Heat-insulating coating additive and production method

A technology of thermal insulation coatings and additives, applied in antifouling/underwater coatings, reflective/signal coatings, coatings, etc., can solve problems such as poor use feeling, poor thermal insulation effect, and poor environmental protection performance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

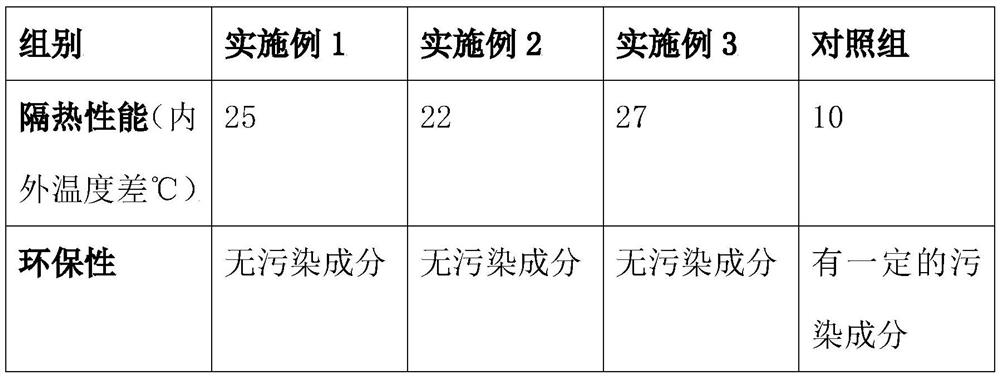

Examples

Embodiment 1

[0027]S1, select 15 parts of nano-titanium dioxide, 15 parts of nano-calcium carbonate and 15 parts of sodium bicarbonate, pour the selected nano-titanium dioxide, nano-calcium carbonate and sodium bicarbonate into the ball mill, start the ball mill to grind and mix the raw materials, and the ball milling time is controlled at In 55 minutes, a mixed powder of nano-titanium dioxide, nano-calcium carbonate and sodium bicarbonate can be obtained;

[0028] S2. Pour 11 parts of polyvinyl alcohol, 20 parts of silica sol and 25 parts of deionized water into the blender, start the blender to mix the three raw materials, raise the stirring temperature of the blender to 100 ° C, at a speed of 105 rpm Stir for 1.5 hours to make it fully mixed to obtain a mixed solution;

[0029] S3. Pour 20 parts of polyamide resin, 9 parts of coupling agent, and 15 parts of polyvinyl alcohol colloid into the mixer, start the mixer to mix and stir, stir and mix at a temperature of 110 ° C for 1.5 hours, ...

Embodiment 2

[0032] S1. Select 10 parts of nano-titanium dioxide, 10 parts of nano-calcium carbonate and 20 parts of sodium bicarbonate, pour the selected nano-titanium dioxide, nano-calcium carbonate and sodium bicarbonate into the ball mill, start the ball mill to grind and mix the raw materials, and the ball milling time is controlled at In 50 minutes, a mixed powder of nano-titanium dioxide, nano-calcium carbonate and sodium bicarbonate can be obtained;

[0033] S2. Pour 8 parts of polyvinyl alcohol, 15 parts of silica sol and 20 parts of deionized water into the blender, start the blender to mix the three raw materials, raise the stirring temperature of the blender to 90 ° C, at a speed of 90 rpm Stir for 1 hour to make it fully mixed to obtain a mixed solution;

[0034] S3. Pour 15 parts of polyamide resin, 6 parts of coupling agent, and 10 parts of polyvinyl alcohol colloid into the mixer, start the mixer to mix and stir, stir and mix at a temperature of 100 ° C for 1 hour, make it ...

Embodiment 3

[0037] S1, select 20 parts of nano-titanium dioxide, 20 parts of nano-calcium carbonate and 25 parts of sodium bicarbonate, pour the selected nano-titanium dioxide, nano-calcium carbonate and sodium bicarbonate into the ball mill, start the ball mill to grind and mix the raw materials, and the ball milling time is controlled at In 60 minutes, a mixed powder of nano-titanium dioxide, nano-calcium carbonate and sodium bicarbonate can be obtained;

[0038] S2. Pour 14 parts of polyvinyl alcohol, 25 parts of silica sol and 30 parts of deionized water into the blender, start the blender to mix the three raw materials, raise the stirring temperature of the blender to 110 ° C, at a speed of 120 rpm Stir for 2 hours to make it fully mixed to obtain a mixed solution;

[0039] S3. Pour 25 parts of polyamide resin, 12 parts of coupling agent, and 20 parts of polyvinyl alcohol colloid into the mixer, start the mixer to mix and stir, stir and mix at a temperature of 120 ° C for 2 hours, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com