Preparation method of organic silicon acrylic ester self-organizing gradient emulsion film

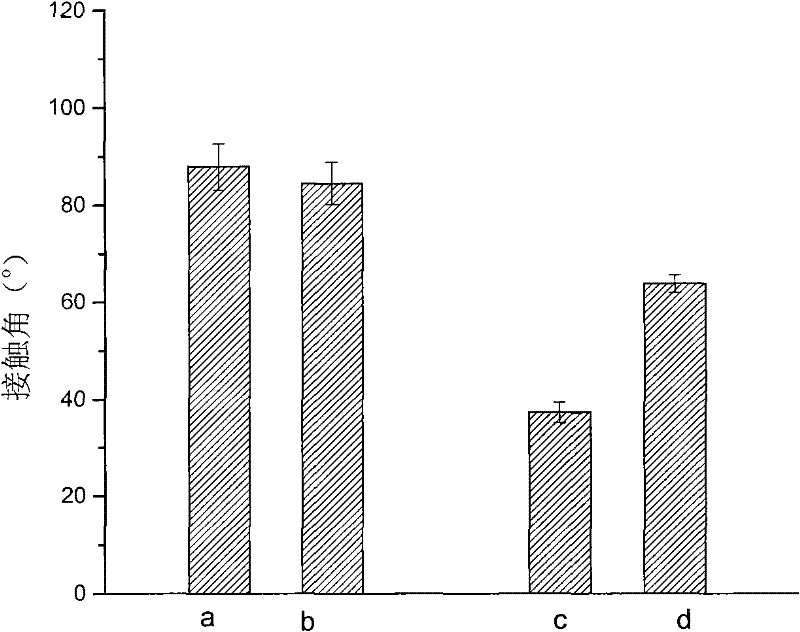

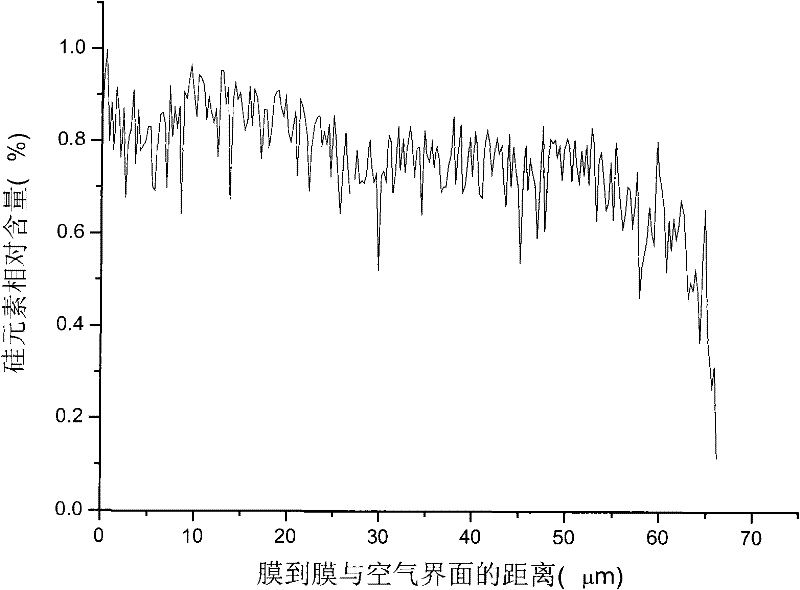

The technology of acrylate and methyl methacrylate is applied in the field of preparation of organosilicon acrylate self-organized gradient latex film, which can solve the problems of complex process, environmental pollution and high energy consumption, and achieves simple preparation method, low energy consumption, The effect of low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] (1) Preparation of pre-emulsion 1:

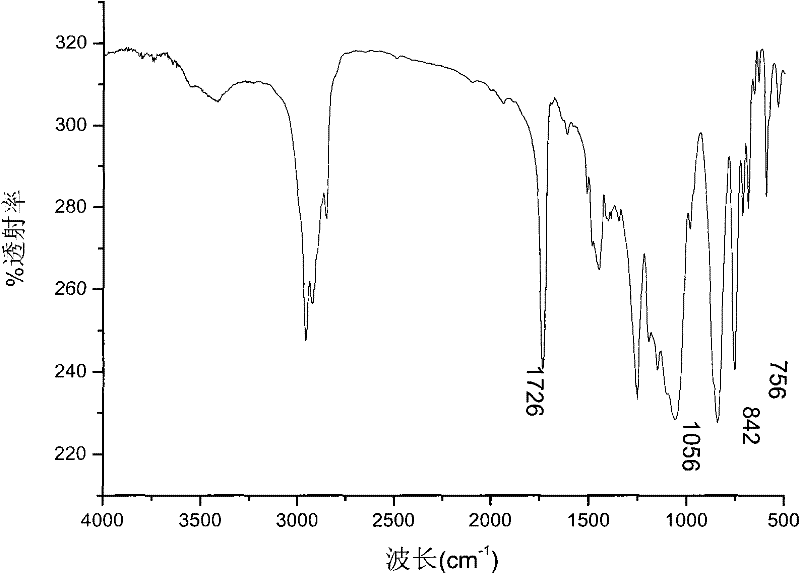

[0024] Add deionized water and sodium 1-propenyl-2-hydroxyalkyl sulfonate into a three-necked flask equipped with a condensing reflux device and a constant-speed feeding device, stir rapidly for 5-60 minutes, then ultrasonicate for 0-20 minutes, and then add a mixing unit body to obtain a pre-emulsion 1; the mixed monomer is composed of two monomers, organosilicon monomer and methyl methacrylate, and the weight ratio of the two monomers is 1:4 to 4:1; the organosilicon monomer refers to γ -Methacryloxypropyl tri(trimethylsiloxy)silane, the amount of 1-propenyl-2-hydroxyl alkyl sodium sulfonate is 4%~10% of the total mass of the two monomers; 1 The structural formula of sodium propenyl-2-hydroxyalkylsulfonate is: CH 2 =CH-CH 2 -O-CH 2 -CH(OH)-CH 2 -SO 3 Na.

[0025] (2) Preparation of pre-emulsion 2:

[0026] Add deionized water and sodium 1-propenyl-2-hydroxyalkylsulfonate into a three-necked flask, stir rapidly for 5 to 60 mi...

Embodiment 1

[0040] Embodiment 1, the preparation of silicone acrylate copolymerization soap-free emulsion:

[0041] Add a certain amount of water and 0.02g sodium 1-propenyl-2-hydroxyalkylsulfonate into a three-necked flask equipped with a condensation reflux device and a constant-speed feeding device, and add mixed monomers (0.1g γ-methylpropene Acyloxypropyltris(trimethylsiloxy)silane, 0.4 g methyl methacrylate). The pre-emulsion was stirred for 5 minutes to obtain pre-emulsion 1. Add the remaining water and 0.04g sodium 1-propenyl-2-hydroxyalkylsulfonate into the three-necked flask, stir quickly and then add the mixed monomer (0.2g γ-methacryloyloxypropyltri(trimethylsilyl oxy) silane, 0.8 g methyl methacrylate). The pre-emulsion was stirred for 5 minutes to obtain pre-emulsion 2. Pass the pre-emulsion 1 with nitrogen for half an hour, add 0.0178g of disodium hydrogen phosphate solution and part of potassium persulfate, raise the temperature to 75°C, react for about half an hour and...

Embodiment 2

[0042] Embodiment 2, the preparation of silicone acrylate copolymerization soap-free emulsion:

[0043] Add a certain amount of water and 0.05g sodium 1-propenyl-2-hydroxyalkylsulfonate into a three-necked flask equipped with a condensing reflux device and a constant-speed feeding device, and after rapid stirring, add mixed monomers (0.4g γ-methylpropene Acyloxypropyltris(trimethylsiloxy)silane, 0.1 g methyl methacrylate,). The pre-emulsion was stirred for 60 minutes, and the ultrasonic wave was used for 20 minutes to obtain pre-emulsion 1. Add the remaining water and 0.1g sodium 1-propenyl-2-hydroxyalkylsulfonate into the three-necked flask, stir quickly and then add the mixed monomer (0.8g γ-methacryloxypropyltris(trimethylsiloxane) base) silane, 0.2 g methyl methacrylate). The pre-emulsion was stirred for 60 minutes, and the ultrasonic wave was used for 20 minutes to obtain the pre-emulsion 2. Pass the pre-emulsion 1 with nitrogen for half an hour, add 0.0178g of disodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com