Multi-unit linear driving planar controllable slip type wood forklift

A linear drive and linear drive technology, applied in mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of weak load capacity, poor mechanical performance of controllable mechanism loading and unloading machinery, etc. , to achieve the effect of improving the bearing capacity, realizing the numerical control of the operation, and avoiding the transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

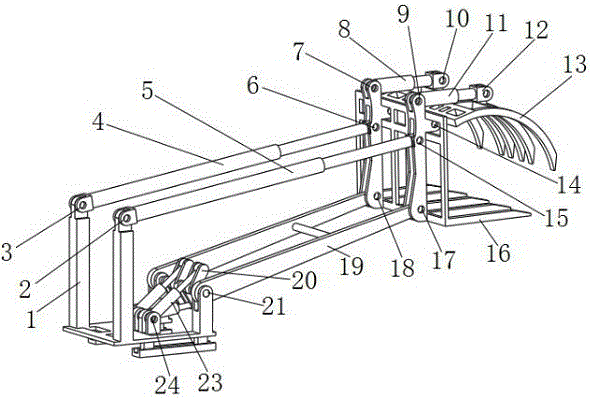

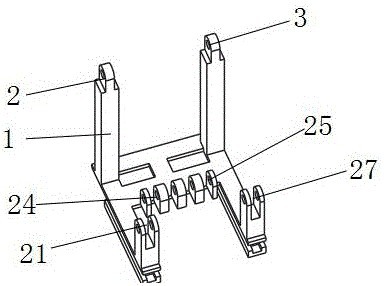

[0026] control figure 1 , a multi-unit linear drive planar controllable sliding forklift according to the present invention includes a multi-unit linear drive mechanism, a boom 19, a bucket control mechanism and a frame 1.

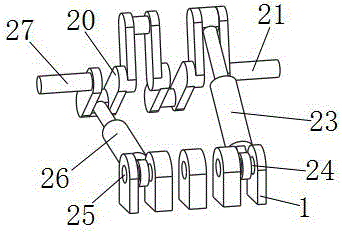

[0027] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , the multi-unit driving mechanism includes a crankshaft 20, a first linear driver 23 and a second linear driver 26, one end of the first linear driver 23 is connected to the frame 1 through the first rotating pair 24, and the other end is connected to the frame 1 through the second The rotary pair 28 is connected to the crankshaft 20 , one end of the second linear drive 26 is connected to the frame 1 through the third rotary pair 25 , and the other end is connected to the crankshaft 20 through the fourth rotary pair 29 . The crankshaft 20 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com