Self-detection indirect heating type rotary furnace

A heating type, rotary furnace technology, applied in the field of heating rotary furnace, bulk material drying, can solve the problems of uneven heating of the furnace barrel, uneven heating, contaminated materials, etc., to achieve uniform heating and stable operation, continuous and stable temperature, The effect of easy maintenance operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

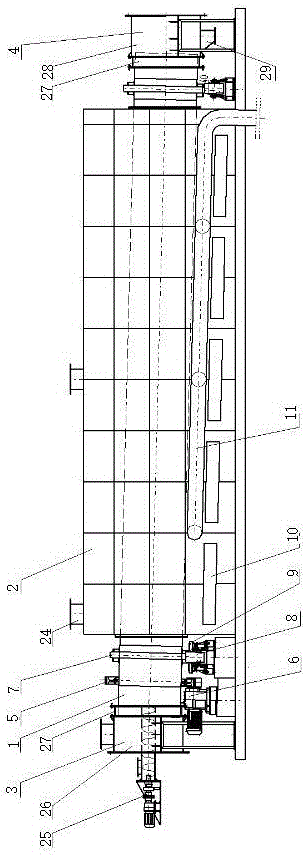

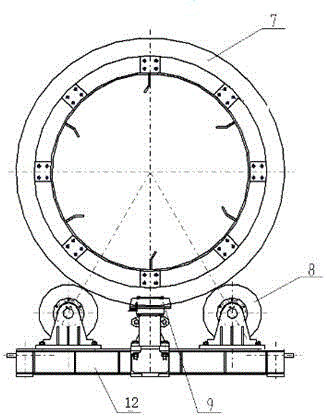

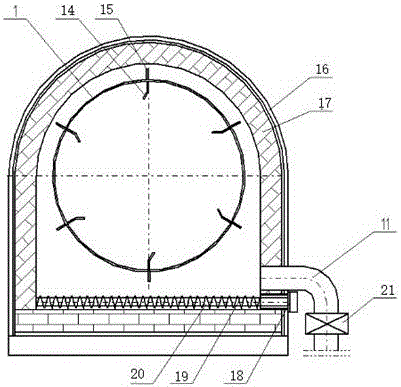

[0031] A self-inspecting indirect heating rotary furnace, comprising a furnace drum 1, a heating furnace 2, a feeding system 3, a discharging system 4, a drive system, and an electrical control system, characterized in that the heating furnace 2 is located in the middle of the furnace 1 One end of the furnace drum 1 is connected to the feeding system 3, and the other end is connected to the discharging system 4. The feeding system 3 transports the material to the heating furnace 2 through the feeding screw conveyor 25, and the driving system provides the transportation force to heat the furnace 2. Electric heating elements are evenly arranged at the bottom, and a hot air system 11 is arranged in the heating furnace 2 through bent pipes. A temperature control detector is installed inside the heating furnace 2, and the heating and heating are intelligently controlled through the electrical control system. After the material is heated, it passes through the The discharge system 4 ...

specific Embodiment 2

[0043] A self-inspecting indirect heating rotary furnace, comprising a furnace drum 1, a heating furnace 2, a feeding system 3, a discharging system 4, a drive system, and an electrical control system, characterized in that the heating furnace 2 is located in the middle of the furnace 1 One end of the furnace drum 1 is connected to the feeding system 3, and the other end is connected to the discharging system 4. The feeding system 3 transports the material to the heating furnace 2 through the feeding screw conveyor 25, and the driving system provides the transportation force to heat the furnace 2. Electric heating elements are evenly arranged at the bottom, and a hot air system 11 is arranged in the heating furnace 2 through bent pipes. A temperature control detector is installed inside the heating furnace 2, and the heating and heating are intelligently controlled through the electrical control system. After the material is heated, it passes through the The discharge system 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com