High-voltage alternating-current circuit breaker arc burning time measuring system and method

A high-voltage AC and arcing time technology, applied in the field of power system power transmission, transformation and distribution, can solve the problems of measurement system measurement, inability to measure arcing time of high-voltage AC circuit breaker breaking test, inability to identify jump characteristic points, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

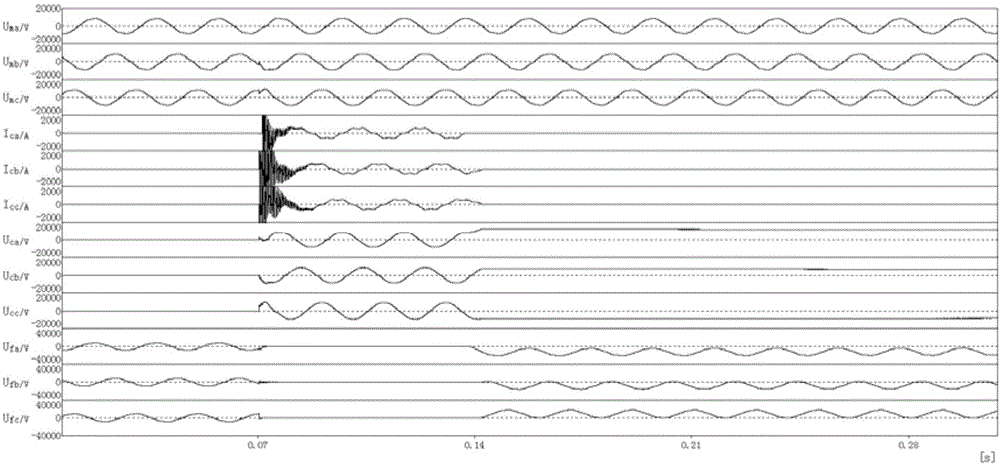

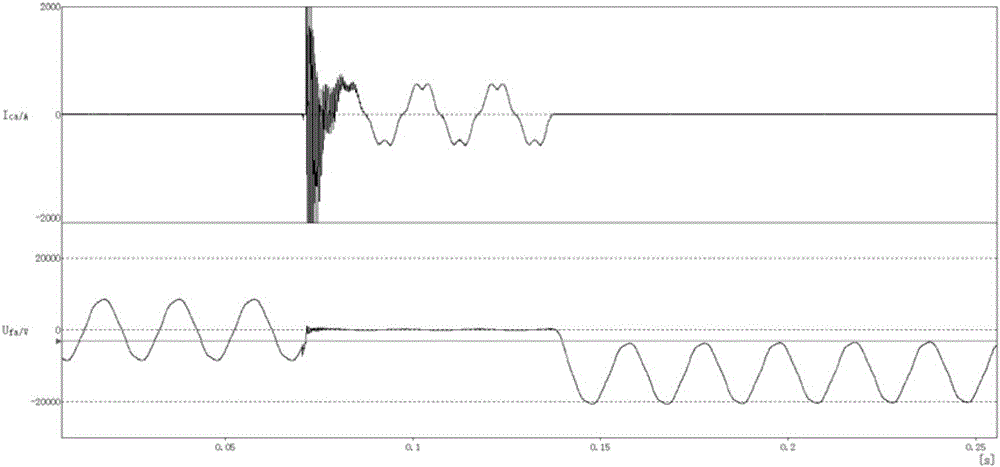

[0065] In this embodiment 1, the arcing time is determined by the current switching test of the AC high-voltage vacuum circuit breaker 400A back-to-back switching capacitor bank conducted by the quality inspection and testing center of the complete set of reactive power compensation equipment in the electric power industry.

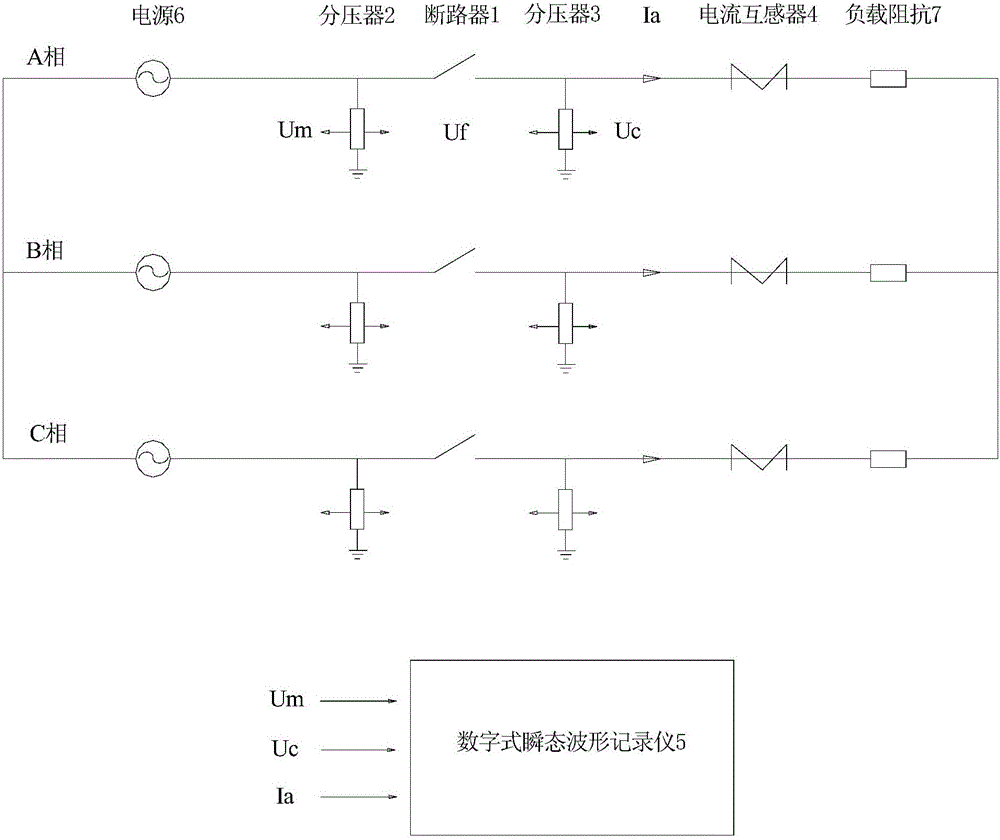

[0066] This embodiment provides a high-voltage AC circuit breaker arcing time measurement system, the schematic diagram of the test circuit is as follows figure 1 As shown, the test product includes a high-voltage AC circuit breaker 1, the bus side (power side) of the high-voltage AC circuit breaker is installed with a bus-side voltage divider 2 to the ground, and the load side of the high-voltage AC circuit breaker is installed with a load-side divider to the ground. A voltage transformer 3, the high-voltage AC circuit breaker 1 is installed in series with a current transformer 4, the bus side voltage divider 2, the load side voltage divider 3, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com