Robot remote ultrasonic induction automatic testing system and control method thereof

An automatic test system and robot technology, applied in the field of remote measurement and control, can solve problems such as low precision, low efficiency of manual testing, long test verification cycle, etc., and achieve the effect of speeding up testing, ensuring accuracy, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

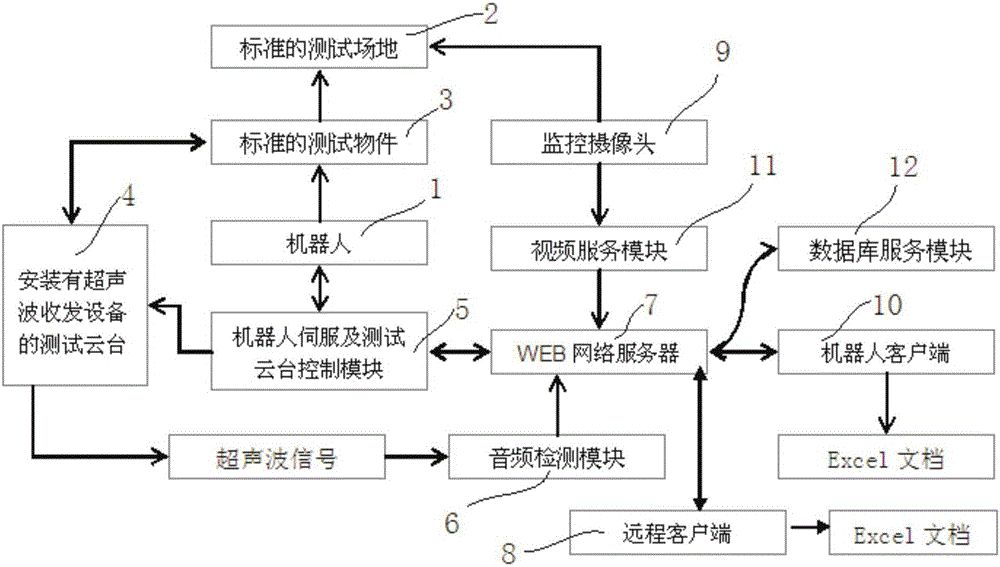

[0062] Robot remote ultrasonic sensing automatic test system, such as figure 1 As shown, the robot is tested by simulating various simulated automobile processing actions, including a robot 1 performing a test action, an industry-standardized test site 2 and a standardized test object 3. Grab and move on the test site 2 to perform various simulation action tests; the test system also includes a test pan-tilt 4, a robot servo and a test pan-tilt control module 5, an audio detection module 6, a WEB network server 7 and a remote client 8, The test platform 4 ensures that the test can be effectively completed at the predetermined test position, and the test platform 4 is a car body for simulating the installation position and direction of the ultrasonic equipment of different vehicle models or the vehicle shell installed with the ultrasonic equipment to simulate the bumper. Rod simulation test cloud platform; remote client 8 is connected with WEB network server 7 network communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com