Sewage treatment method and sewage treatment device

A sewage treatment method and sewage treatment device technology, which is applied in water/sewage treatment, light water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of loss of purification effect, death of bacteria, high operating cost, etc., and achieve simplification Sewage treatment technology, effect of improving effect and reducing operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

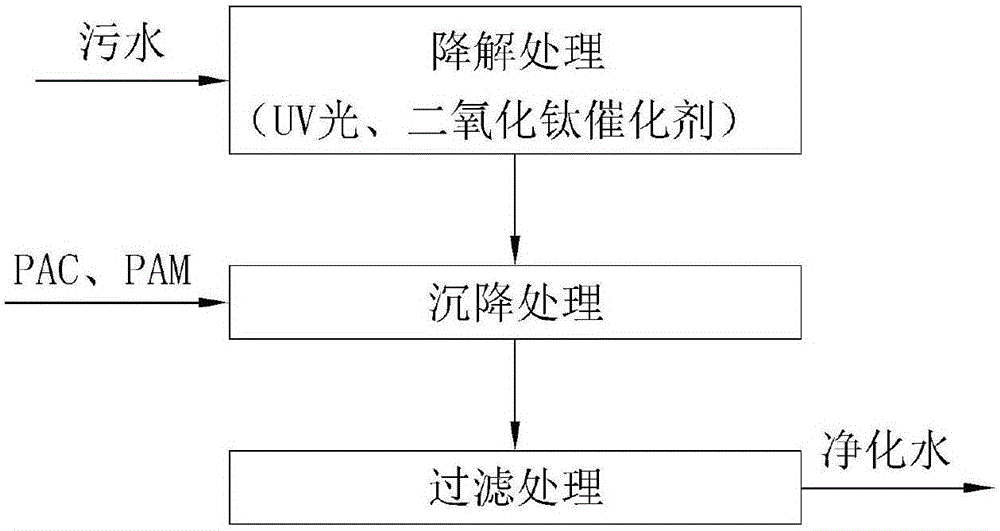

[0043] The present embodiment provides a kind of sewage treatment method, and it comprises the following steps successively:

[0044] (1) Pass the sewage into the degradation zone, and degrade it under the irradiation of UV light and the catalysis of titanium dioxide;

[0045] (2) Pass the degraded sewage into the sedimentation area for sedimentation treatment;

[0046] (3) Pass the supernatant of the sewage after sedimentation treatment into the filter area for filtration treatment, so that the filtered effluent can meet the water quality standard for reclaimed water

[0047] In order to improve the effect of sedimentation treatment, preferably, PAC and PAM are also added during the sedimentation treatment in step (2), so that the sedimentation effect can be better improved through the adsorption of PAC and PAM.

[0048] Meanwhile, the duration of the sedimentation treatment in step (1) is preferably 1-2 hours.

[0049] Its workflow is as follows figure 1 As shown, the sew...

Embodiment 2

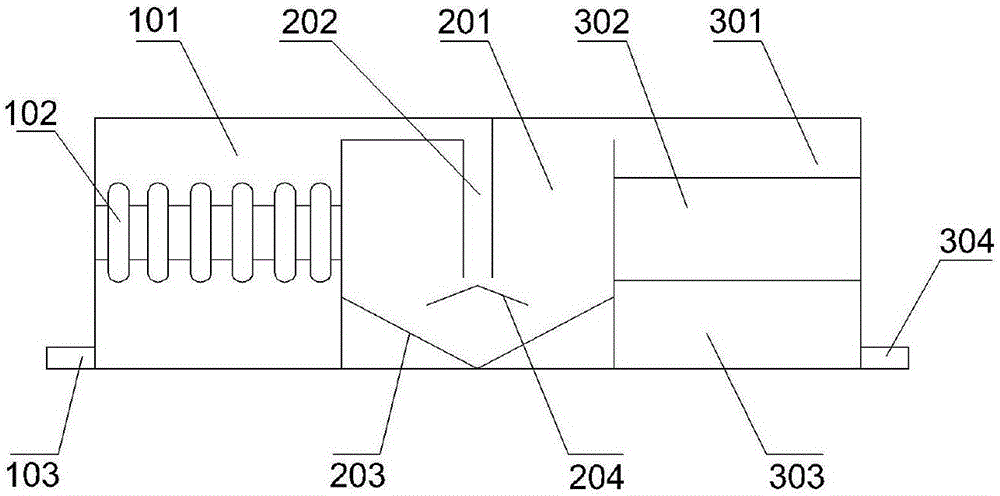

[0051] Such as figure 2 As shown, this embodiment provides a sewage treatment device based on the sewage treatment method in Example 1, which includes a degradation chamber 101 , a sedimentation chamber 201 and a filtration chamber 301 arranged in sequence.

[0052] The degradation chamber 101 is provided with a water inlet 103 , a titanium dioxide catalyst and several UV lamps 102 ;

[0053] The settling chamber 201 is provided with a central guide pipe 202, an umbrella-shaped reflector 204, an overflow weir and a conical sedimentation bucket 203; the conical sedimentation bucket 203 is arranged at the bottom of the sedimentation chamber 201; the central guide pipe 202 and The umbrella-shaped reflectors 204 are all arranged above the conical sedimentation bucket 203 , and the umbrella-shaped reflectors 204 are arranged below the water outlet end of the central draft pipe 202 .

[0054] Wherein, preferably, the conical sedimentation bucket 203 , the umbrella-shaped reflector 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com