Water-soluble coating resisting dish washing machine and preparation method of water-soluble coating

A water-soluble paint, washable technology, applied in the direction of coating, etc., can solve the problems of failing to meet export standards and affecting the development of enterprises, and achieve the effects of improving the scope of application, good water boiling resistance and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

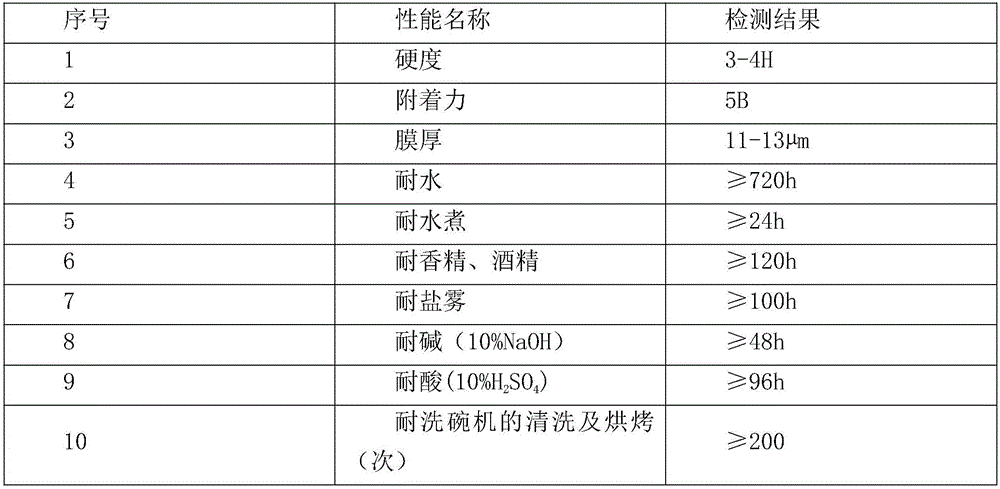

Examples

Embodiment 1

[0026] A kind of dishwasher-resistant water-soluble paint of the present invention includes the following raw materials in parts by mass: 16 parts of water-based epoxy modified silicone resin, 24 parts of water-based polyester modified acrylic resin, and partially methylated melamine resin 10 parts, 2.5 parts of modified silane coupling agent, 8 parts of ethylene glycol monobutyl ether, 12 parts of isobutanol, 2.5 parts of pH regulator, 6 parts of pre-dispersed pigment, and 19 parts of deionized water.

[0027] A preparation method of a dishwasher-resistant water-soluble paint, comprising the following steps:

[0028] a. Weigh 16 parts of water-based epoxy-modified silicone resin and 24 parts of water-based polyester-modified acrylic resin and place them in a container, stir evenly, add 10 parts of partially methylated melamine resin, and stir for 3 minutes;

[0029] b. Add 2.5 parts of modified silane coupling agent while stirring the mixed solution obtained in step (a), and ...

Embodiment 2

[0036] A dishwasher-resistant water-soluble coating of the present invention comprises the following raw materials in parts by mass: 18 parts of water-based epoxy modified silicone resin, 18 parts of water-based polyester modified acrylic resin, and partially methylated melamine resin 8 parts, 2 parts of modified silane coupling agent, 9 parts of ethylene glycol monobutyl ether, 10 parts of isobutanol, 2 parts of pH regulator, 8 parts of pre-dispersed pigment, 25 parts of deionized water.

[0037] A preparation method of a dishwasher-resistant water-soluble paint, comprising the following steps:

[0038] a. Weigh 18 parts of water-based epoxy-modified silicone resin and 18 parts of water-based polyester-modified acrylic resin and place them in a container, stir evenly, add 8 parts of partially methylated melamine resin, and stir for 3 minutes;

[0039] b. Add 2 parts of modified silane coupling agents while stirring the mixed solution obtained in step (a), and stir for 3 minut...

Embodiment 3

[0046] A dishwasher-resistant water-soluble coating of the present invention comprises the following raw materials in parts by mass: 17 parts of water-based epoxy modified silicone resin, 20 parts of water-based polyester modified acrylic resin, and partially methylated melamine resin 8.5 parts, 2.2 parts of modified silane coupling agent, 11 parts of ethylene glycol monobutyl ether, 11 parts of isobutanol, 3 parts of pH regulator, 7 parts of pre-dispersed pigment, 20.3 parts of deionized water.

[0047] A preparation method of a dishwasher-resistant water-soluble paint, comprising the following steps:

[0048]a. Weigh 17 parts of water-based epoxy-modified silicone resin and 20 parts of water-based polyester-modified acrylic resin and place them in a container, stir evenly, add 8.5 parts of partially methylated melamine resin, and stir for 3 minutes;

[0049] b. Add 2.2 parts of modified silane coupling agent while stirring the mixed solution obtained in step (a), and stir fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com