Unbounded prestress and steel plate-concrete combined reinforcing design method of T-type beam

A design method and non-bonding technology, applied in bridge reinforcement, bridge construction, bridges, etc., can solve the problems of reducing the resonance effect between prestressed tendons and structures, high maintenance costs, and maintenance difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Such as figure 1 The design method of unbonded prestressed and steel plate-concrete combined reinforcement of a T-shaped beam includes the following steps:

[0080] Step 1. Combination reinforcement structure determination: determine the unbonded prestressed and steel plate-concrete composite reinforcement structure of the reinforced T-beam 3; the reinforced T-beam 3 is a reinforced concrete beam;

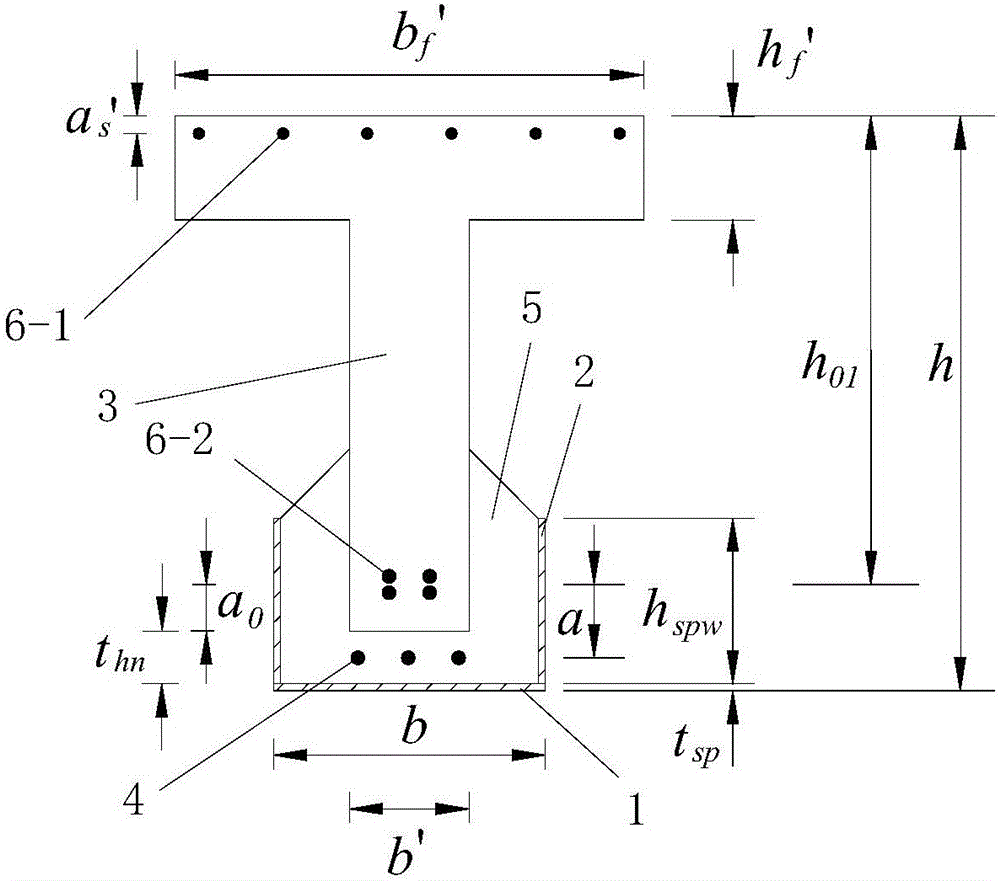

[0081] Such as figure 2 As shown, the combined reinforcement structure of unbonded prestress and steel plate-concrete includes a bottom steel plate 1 arranged under the area to be reinforced of the T-beam 3 to be reinforced, and two steel plates arranged on the left and right sides of the area to be reinforced respectively. The longitudinal side steel plates 2 and two end-blocking steel plates respectively arranged at the front and rear ends of the area to be reinforced, the bottom steel plate 1 and the two longitudinal side steel plates 2 are arranged in the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com