Method for recovering extra-heavy oil and super-heavy oil in horizontal well fire flooding assisted gravity drainage mode

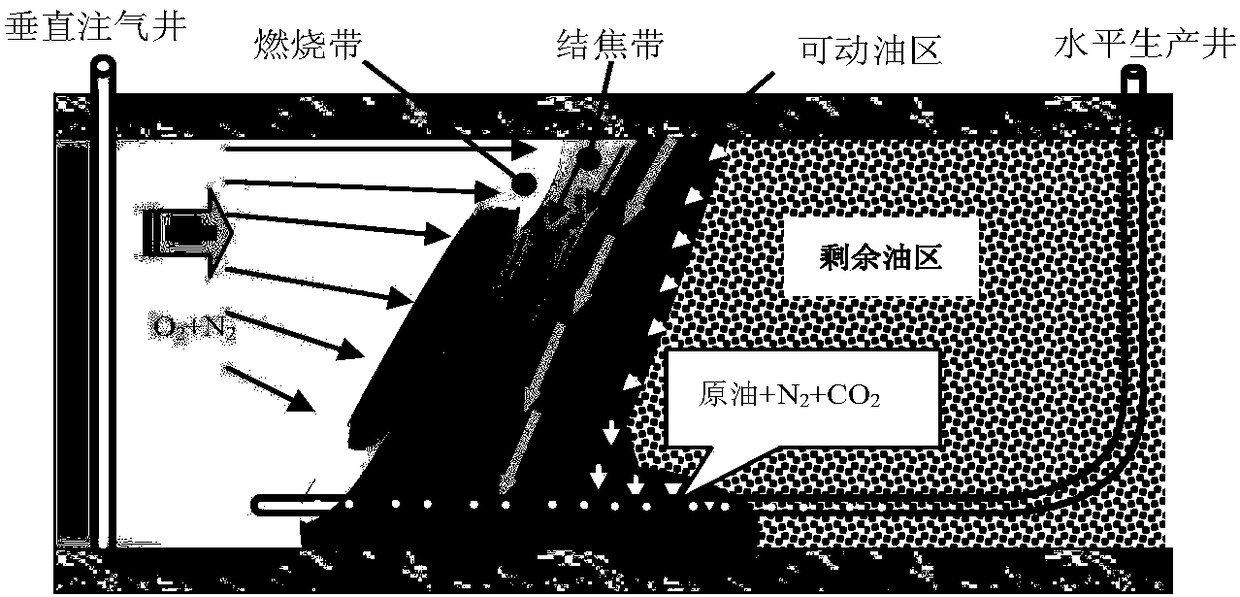

A technology for assisting gravity and horizontal wells, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc. It can solve the problems of increased ground danger, shut-in of injection wells, and enlarged lateral sweep, etc., so as to improve the sweep coefficient. , The effect of small investment in drilling and completion and avoiding one-way migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、1

[0044] Example 1. Indoor physical simulation of 1 vertical well + 4 horizontal wells

[0045] This embodiment is an indoor physical simulation mining of one vertical gas injection / ignition well corresponding to four horizontal production wells. in:

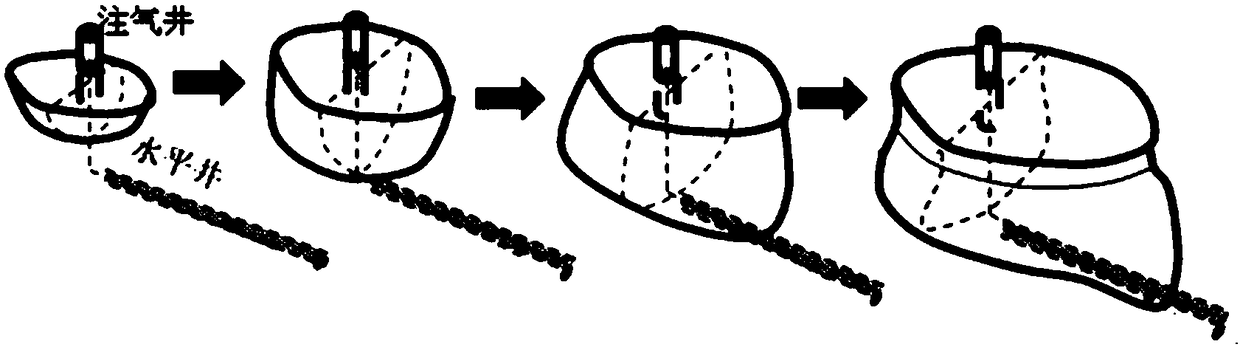

[0046] 1) Using the sand packing model to simulate the feasibility of the development mode of fire flooding assisted gravity drainage with 1 vertical well + 4 horizontal wells in the reservoir, see Figure 3C and Figure 5 , model size (see Figure 5 ): 60cm×60cm×20cm, the length of the horizontal well section is 25cm, the matrix is simulated by quartz sand + 7% clay, the porosity is 38%, the oil saturation is 75%, and the crude oil viscosity at 50°C is 100,000mpa.s.

[0047] 2) Four horizontal wells are located in the middle and lower part of the model, completed with screens, and one vertical well is completed with perforation, and the perforation section is the upper 1 / 3.

[0048] 3) The electric ignition method, the elec...

Embodiment 2

[0052] Reservoir 2 The reservoir depth is 1060m; the total thickness is 25m; the reservoir permeability is 478×10 -3 μm 2 ; The viscosity of crude oil is 48000mPa.s; the oil saturation is 55.9%. The block belongs to an anticline structure without interlayers.

[0053] 1) According to the geological structure characteristics of the block, the well pattern is designed to maximize the control degree (reserves) of the formation. In this embodiment, one vertical gas injection / ignition well corresponds to three horizontal production wells (1 vertical well + 3 horizontal wells) injection-production well pattern ( Figure 6 );

[0054] 2) Three horizontal wells (H1, H2, H3) are located in the middle and lower part of the reservoir, and the plane projection distance between the tip of each horizontal well and the vertical well is about 4m; , H3 horizontal section length is 300m, 250m, 400m, perforated completion, 1 vertical well perforated completion, the perforated section is the u...

Embodiment 3

[0060] Reservoir 3 The reservoir depth is 610m; the total thickness is 30m; the reservoir permeability is 1500×10 -3 μm 2 ; The viscosity of crude oil is 100000mPa.s; the oil saturation is 83%.

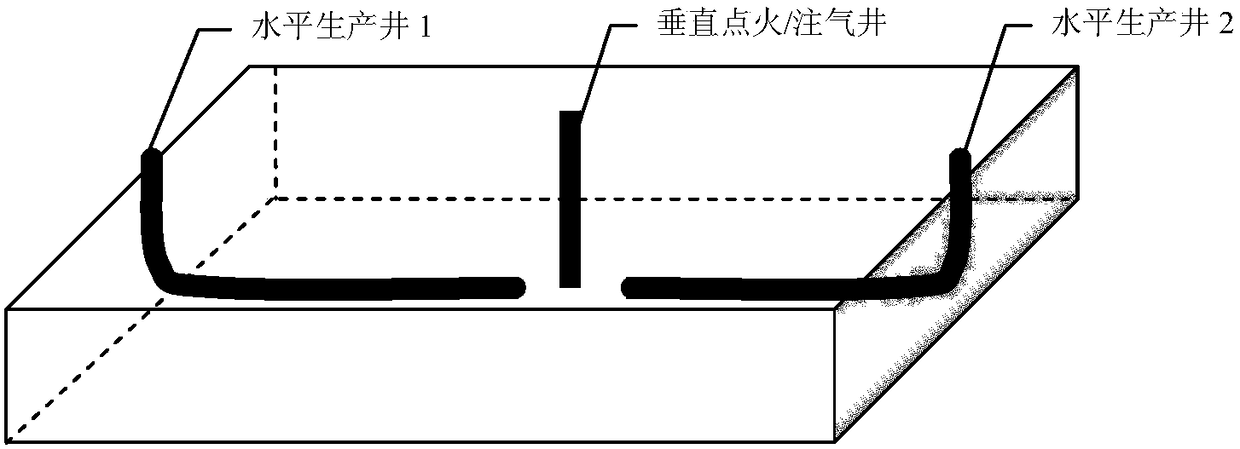

[0061] 1) According to the geological structure characteristics of the block, the well pattern is designed to maximize the control degree (reserves) of the formation, so 1 vertical well + 2 horizontal wells ( Figure 7 );

[0062] 2) The two horizontal wells are located in the middle and lower part of the model, and the plane projection distance between the toe of each horizontal well and the vertical well is about 4.5m; the distance between the horizontal section of each horizontal well and the bottom of the oil layer is about 1.5m, and the length of the H1 and H2 horizontal well sections is 450m , 350m, perforation completion, 1 vertical well perforation completion, perforation section is the upper 1 / 3;

[0063] 3) First, the vertical well is connected with the two horizontal wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com