Wheat straw drying box

A drying box and wheat straw technology, which is applied in the direction of biomass drying, drying room/container, drying gas arrangement, etc., can solve the problems of needing a certain amount of time, prolonging the production cycle, and reducing the production efficiency of wheat straw paintings, so as to reduce the processing cycle , increase production efficiency, and facilitate use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

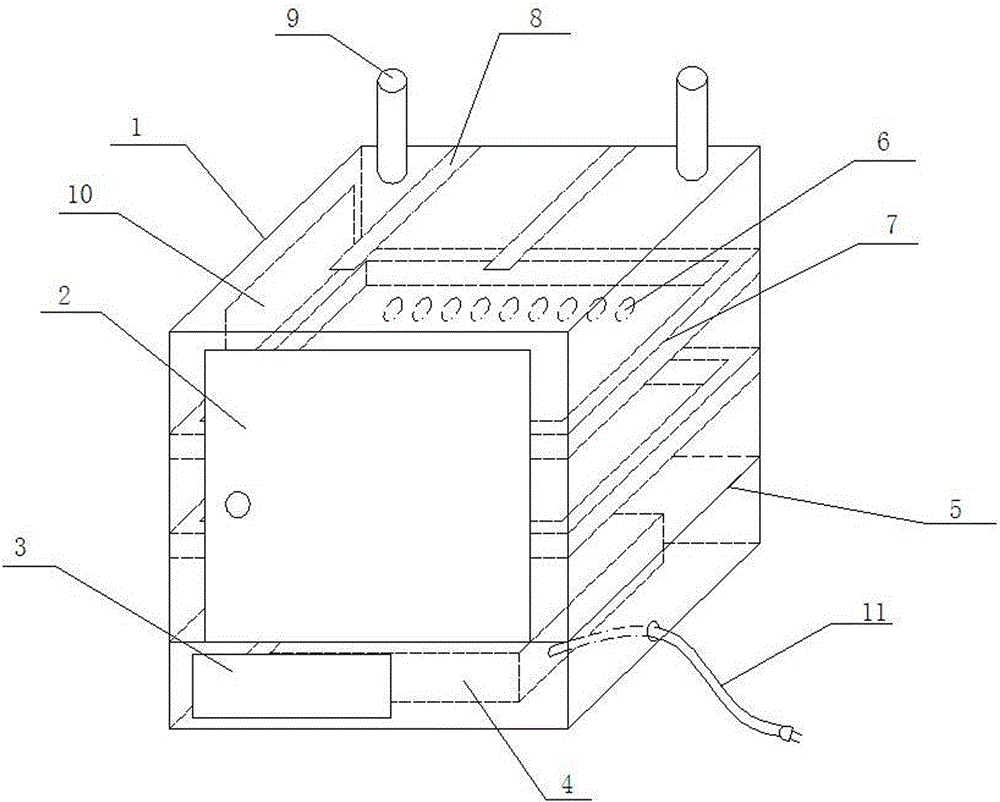

[0019] A wheat straw drying box, comprising a box body 1; it is characterized in that: a box door 2 is provided on the front of the box body 1, and a touch display 3 is provided under the box door 2; There is a control circuit board 4; a partition 5 is arranged above the control circuit board 4; a plurality of drying trays 7 are arranged above the partition 5; a fan 10 is arranged on one side of the drying tray 7; the box body 1 An infrared heat wave tube 8 is arranged on the top of the interior; a plurality of air circulation pipes 9 are arranged on the top of the box body 1 ;

[0020] A plurality of through holes 6 are provided on the bottom surface of each drying tray 7 .

[0021] A temperature and humidity sensor is provided inside the box body 1 , and the temperature and humidity sensor is connected to a control circuit board 4 .

[0022] The control circuit board 4 is provided with a power line 11 , and the power line 11 passes through the side wall of the box b...

Embodiment 2

[0025] The working principle of the present invention:

[0026] In the present invention, by setting relevant functions in the control circuit board 4, the relevant devices inside and outside the box body 1 are controlled, so that the fan 10 blows the air inside the box body 1 to form an air circulation inside the box body 1; The wave tube 8 heats the internal control of the cabinet 1 to achieve the effect of thermal drying; through the temperature and humidity sensor inside the cabinet 1, it is convenient to collect the internal data of the cabinet 1, so as to prompt whether to open the air circulation tube 9 to make the air inside the cabinet 1 Circulation and discharge of moisture; and the touch display 3 on the box 1 displays relevant data inside the box 1, and the drying time and drying temperature can be set through the touch display 3.

Embodiment 3

[0028] In the present invention, the power cord 11 is connected to an external power supply to supply electric energy to related equipment inside the box body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com