Scale removal equipment and method of plate heat exchanger

A technology of plate heat exchangers and heat exchangers, which is applied to the types of heat exchangers, indirect heat exchangers, lighting and heating equipment, etc., which can solve problems such as equipment corrosion, increased circulation resistance, and waste of heat energy, and achieve extended use Long life, improved heat transfer efficiency, and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

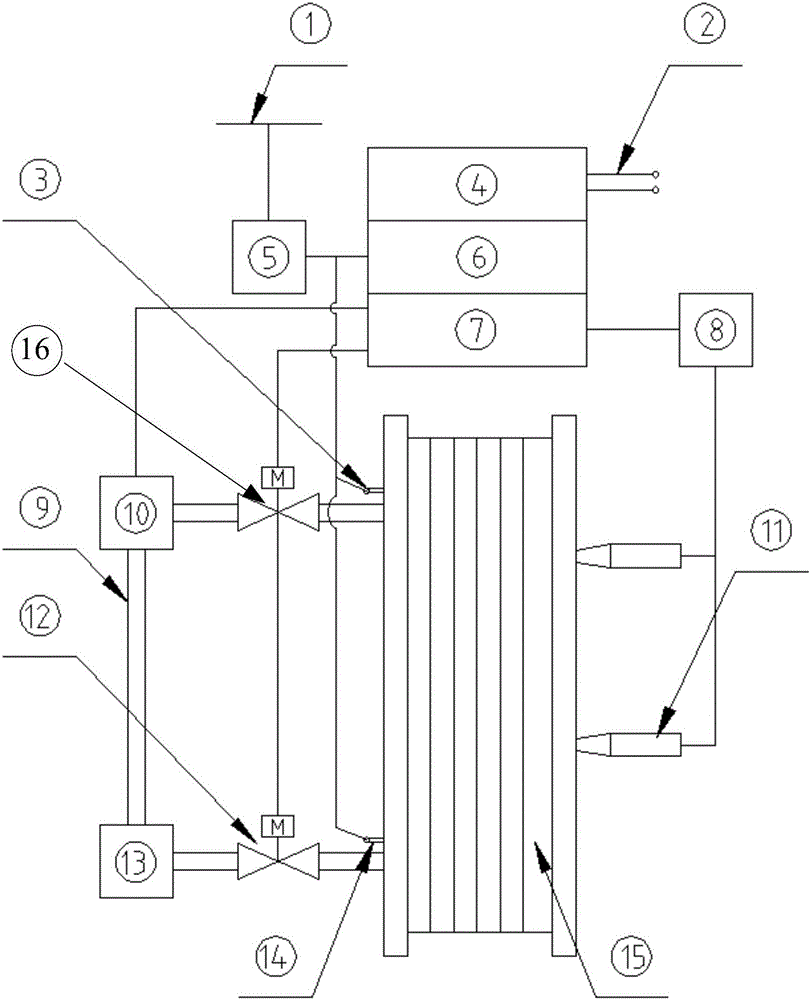

[0013] Such as figure 1 As shown, a plate heat exchanger descaling equipment includes a plate heat exchanger body 15, an ultrasonic generator 8, a gas pulse generator 10, an electric control device 7, a first valve 12, a circulation pipe 9, and a display operating system 1 , a communication module 5, a control device 4, and a buffer expansion container 13. The gas pulse generating device 10 is connected to the second valve 16 through a pipeline, the second valve 16 is connected to the plate heat exchanger body 15, the heat exchanger body 15 is connected to the first valve 12 through a pipeline, and the first valve 12 is connected to the buffer expansion vessel 13 Connected, the buffer expansion vessel 13 is connected to the gas pulse generator 10 through the circulation pipe 9, the gas pulse generator 10-the second valve 16-the plate heat exchanger body 15-the first valve 12-the circulation pipe 9-the gas pulse generator 10 The pipes are connected to each other to form a clos...

Embodiment 2

[0028] Correspondingly, the present invention also provides a method for descaling a plate heat exchanger, including the following steps, S100: installing an ultrasonic generator 8 and a gas pulse generator 10 on the plate heat exchanger body 15; The ultrasonic generator 8 and the gas pulse generator 10 descale the plate heat exchanger.

[0029] Further, it also includes setting a first signal collector 3 at the inlet of the plate heat exchanger body 15, and setting a second signal collector 14 at the outlet, and the first signal collector 3 and the second signal collector 14 are all connected to the industrial computer 6, and the industrial computer 6 sends the collected data to the electronic control device 7 after processing. The industrial computer 6 obtains the temperature difference or pressure difference between the inlet and outlet of the heat exchanger body 15 from the first signal collector 3 and the second signal collector 14, and when the difference temperature dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com