A kind of intelligent takeover sewage control method

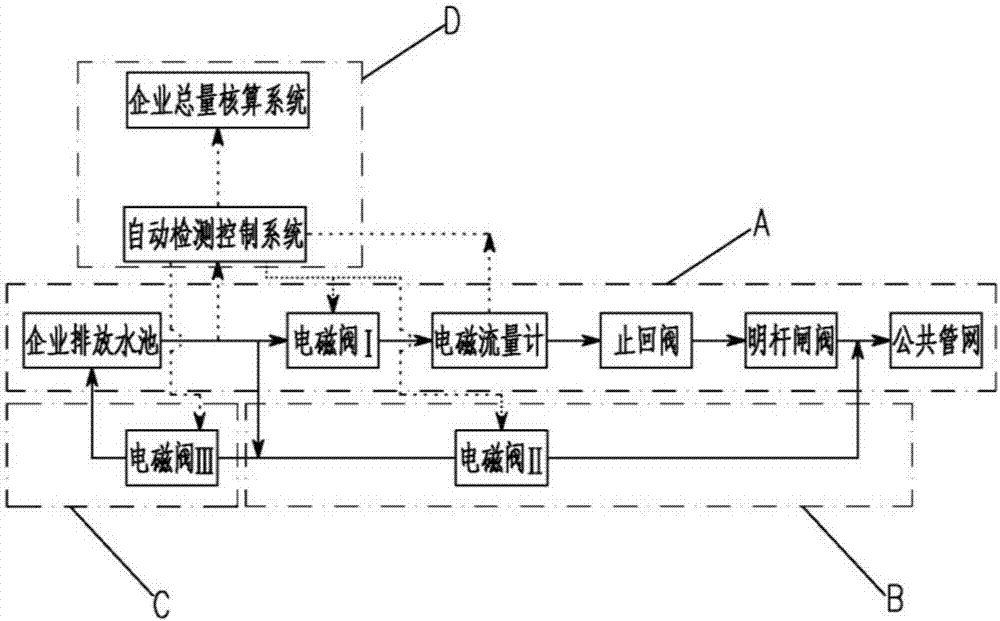

A control method and intelligent technology, applied in water/sewage treatment, electrical program control, chemical instruments and methods, etc., can solve the problem of waste water volume and water quality difficult to monitor in real time, unreasonable distribution of total pollutants, and poor prevention of accident risks, etc. To achieve the effect of reasonable control of the total amount of pollutants, transparent management concepts, and reduction of human intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

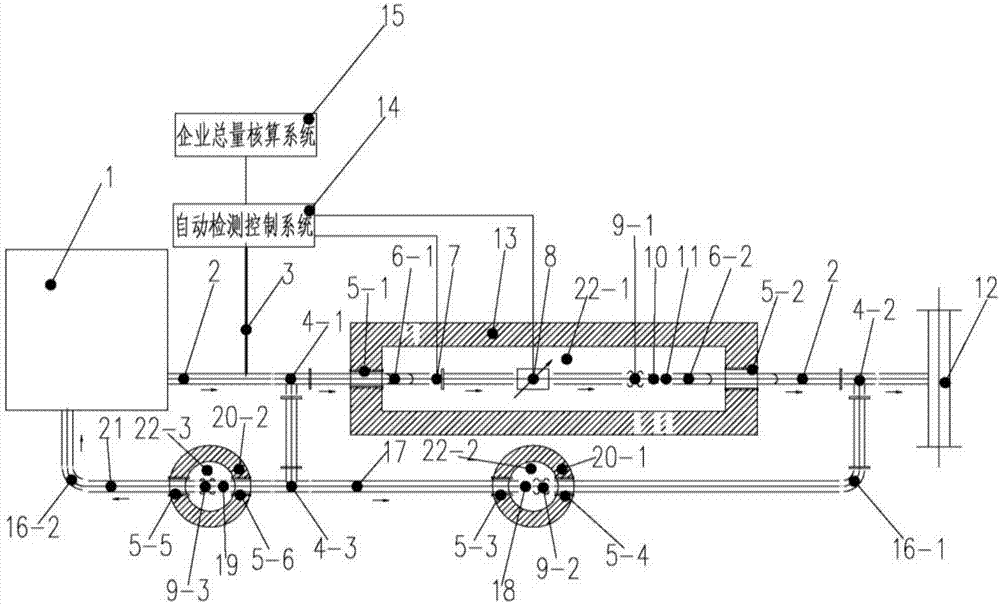

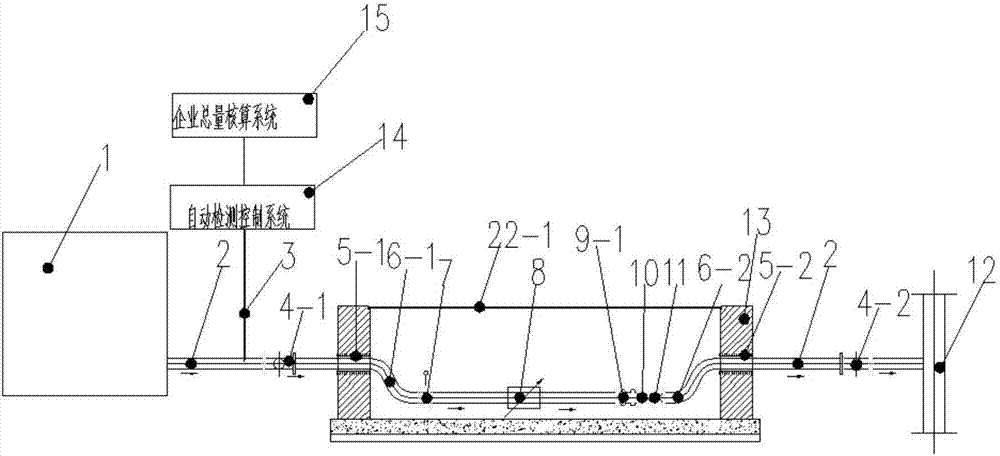

[0067] combine Figure 2-3, the difference from the specific implementation in this embodiment is that the intelligent drainage system A also includes a sewage pipe 2 (connection between the components and the function of transporting sewage), a tee-4-1 (the forced discharge system B connected with return system C), tee two 4-2 (for connecting forced discharge system B and public pipe network 12), waterproof casing one 5-1 (for connecting sewage pipe 2 and square inspection well 13 ), waterproof casing two 5-2 (used to connect sewage pipe 2 and square inspection well 13), 90° elbow one 6-1 (can ensure smooth water flow), 90° elbow two 6-2 (can ensure stable water flow), expansion joint 1 9-1 (can absorb the damage to the pipeline due to external reasons, and can also reduce vibration and noise, and is one of the indispensable tools for pipeline repair), square inspection well 13 (convenient for inspection , maintenance and installation) and FRP cover plate-22-1 (to facilitate...

Embodiment 2

[0069] combine Figure 2-3 , The difference from the specific implementation in this embodiment is that the forced discharge system B also includes a three-way three 4-3 (connecting the return system C, the intelligent discharge system A and the forced discharge system B), a bypass pipe 17 (sewage Able to flow in the forced discharge system B), waterproof casing three 5-3 (for connecting the bypass pipe 17 and the circular inspection well one 20-1), waterproof casing four 5-4 (for connecting the bypass pipe 17 and circular inspection well 1 20-1), solenoid valve Ⅱ 18 (controlling forced discharge system B drainage), expansion joint 2 9-2 (absorbing damage to the pipeline due to external reasons, and can also reduce vibration and noise, It is one of the indispensable tools for pipeline repair), bypass pipe 90° elbow 16-1 (to ensure smooth water flow), circular inspection well 1 20-1 (convenient for inspection, maintenance and installation) and FRP cover plate 2 22 -2 (to facil...

Embodiment 3

[0072] combine Figure 2-3 In this embodiment, the difference from the specific implementation is that the backflow system C also includes waterproof casing five-5-5 (circular inspection well two 20-2 and return pipe 21), waterproof casing six 5-6 (Circular inspection well 2 20-2 and return pipe 21), circular inspection well 2 20-2 (convenient for inspection, maintenance and installation), expansion joint 3 9-3 (absorbing damage to the pipeline due to external reasons) , can also reduce vibration and noise, it is one of the indispensable tools for pipeline repair), bypass pipe 90° elbow II 16-2 (to ensure stable water flow), return pipe 21 (conveying return sewage) and FRP cover plate III 22 -3 (to facilitate observation of the circular inspection well II 20-2, and to protect the circular inspection shaft II 20-2 from being crushed by heavy objects); wherein:

[0073] One end of the return pipe 21 communicates with the left port of the tee three 4-3, and the upper port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com