Preparation method for molybdenum carbide/ graphene nanoribbonn composite material

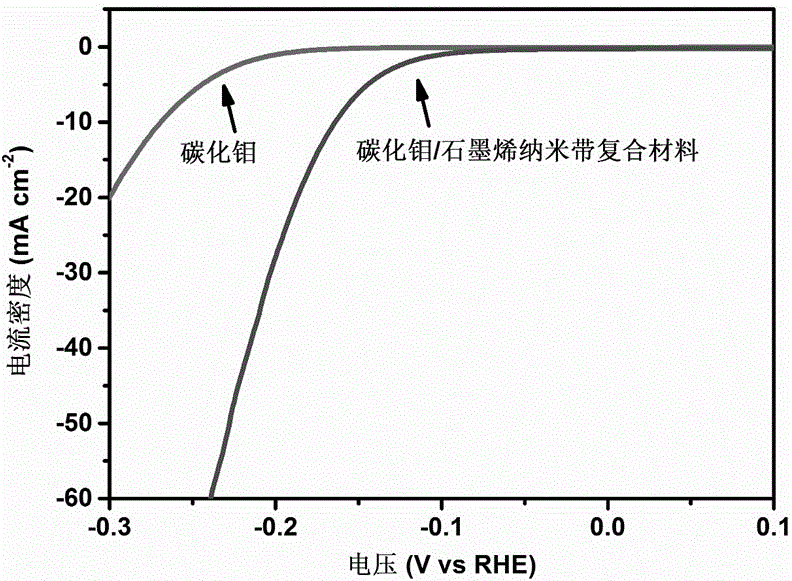

A graphene nanoribbon and composite material technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of affecting catalytic properties, and the electrochemical active sites cannot be fully exposed, and achieve good catalytic performance. , Effective and fast preparation method, the effect of enhancing electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

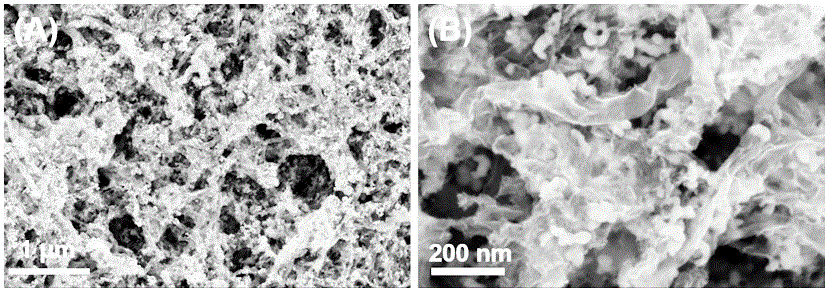

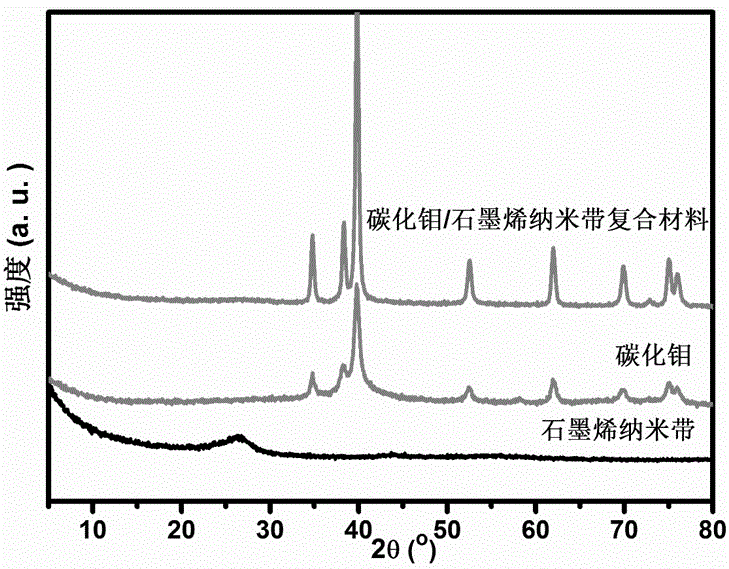

[0030] Example 1 、 This embodiment includes the following steps:

[0031] (1) Dissolve 100 mg ammonium heptamolybdate and 25 mg glucose in 20 mL water to prepare a uniform salt solution;

[0032] (2) Dilute 20 mL to a concentration of 2 mg mL -1 The graphene oxide nanoribbon aqueous dispersion liquid is dropped into the mixed salt solution obtained in step (1), and stirred for a period of time to form a uniform dispersion liquid;

[0033] (3) The mixture obtained in step (2) was subjected to hydrothermal reaction at 180°C for 12 h;

[0034] (4) The product obtained in step (3) was centrifuged, the precipitate was washed and dried, and then carbonized at a high temperature under the protection of a nitrogen atmosphere. The carbonization temperature was 900 ° C, and the carbonization time was 2 hours. 2 C-GNR-1.

Embodiment 2

[0036] The quality of ammonium heptamolybdate in embodiment 1 becomes 200 mg, the quality of glucose becomes 50mg, all the other are the same as embodiment 1, and the composite material finally obtained is denoted as Mo 2 C-GNR-2.

Embodiment 3

[0038] The quality of ammonium heptamolybdate in Example 1 is changed to 400 mg, the quality of glucose is changed to 100 mg, all the other are the same as in Example 1, and the composite material finally obtained is denoted as Mo 2 C-GNR-3.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap