Control method and device for DC contactor for rail transit

A DC contactor and rail transit technology, applied in relays, electrical components, circuits, etc., can solve problems such as increased contact resistance, increased material costs, and failure to connect, so as to improve voltage adaptability and temperature adaptability and prolong service life The effect of long life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

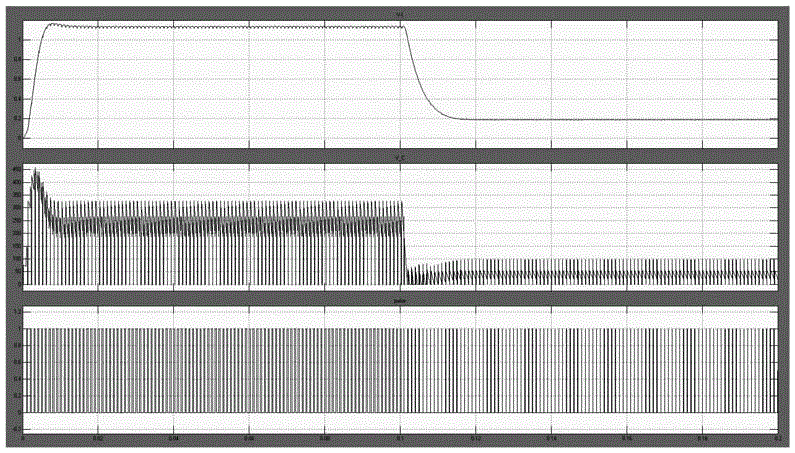

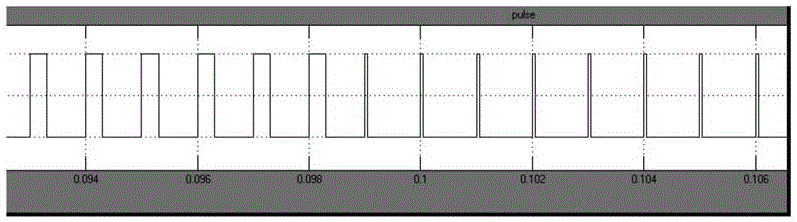

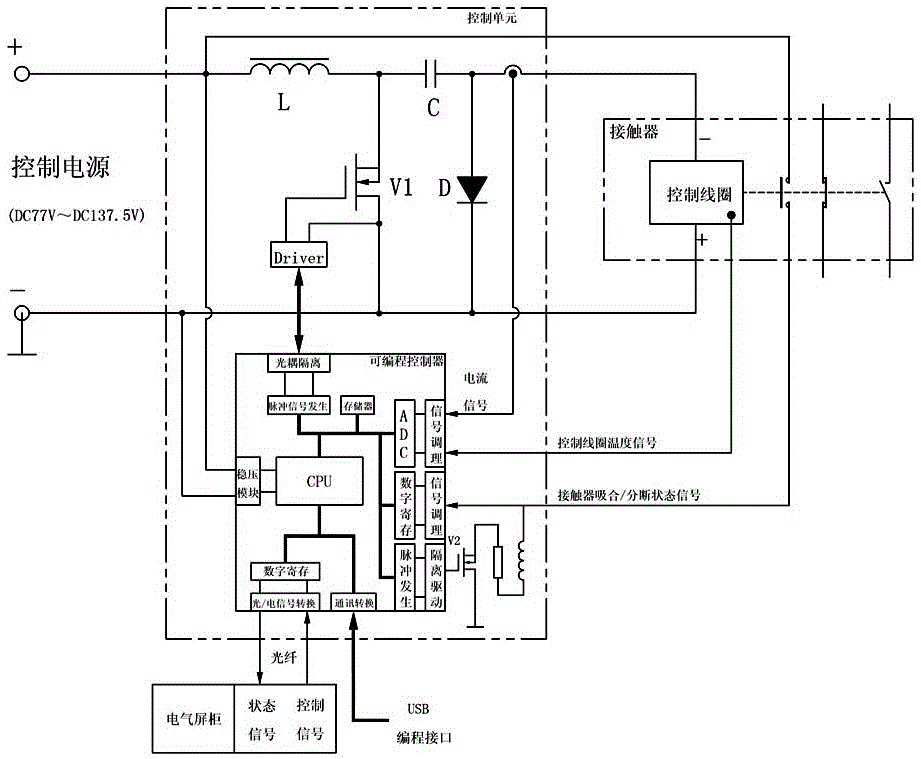

[0026] Such as Figure 1 to Figure 3 As shown, the control method of the DC contactor for rail transit in this embodiment, the specific process is: in the DC contactor pull-in control stage, output a wide pulse voltage to the DC contactor coil so that the coil current reaches the pull-in current; In the closing and holding phase of the DC contactor, a narrow pulse voltage is output to the coil to reduce the coil current from the pull-in current to the hold current. Since the electromagnetic force of the coil is proportional to the square of the coil current, it has no direct relationship with the voltage; therefore, the present invention takes the coil current as the control target and adopts the voltage source pulse width modulation (PWM) control method; when the power supply voltage is low / high When the pulse width is increased / decreased acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com