Master batch and use thereof

A masterbatch, organic substrate technology, applied in railway braking systems, railway car body parts, transportation and packaging, etc., can solve the problems of inability to lighten weight, poor dispersibility, high melt viscosity, and achieve the effect of good disposal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0129] Hereinafter, examples of the present invention will be specifically described. Moreover, this invention is not limited to these Examples. In the following examples and comparative examples, unless otherwise specified, the so-called "%" means "% by weight", and the so-called "part" means "parts by weight".

[0130] Before the examples, production examples of various heat-expandable microspheres are given. Hereinafter, thermally expandable microspheres may be referred to as "microspheres" for simplicity.

[0131] 〔Measurement of average particle diameter and particle size distribution〕

[0132] A laser diffraction particle size distribution analyzer (HEROS & RODOS manufactured by Sympatec Corporation) was used. The dispersion pressure of the dry dispersing module is 5.0 bar, and the vacuum degree is 5.0 mbar. It is measured by a dry measurement method, and the D50 value is taken as the average particle diameter.

[0133] Determination of expansion start temp...

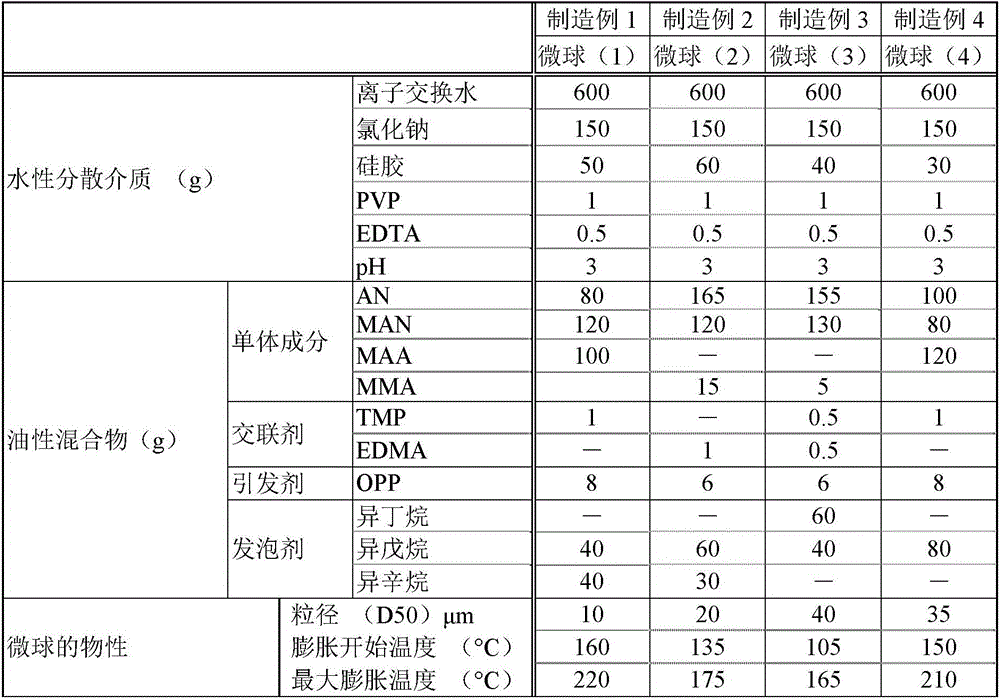

manufacture example 2~4

[0147] Thermally expandable microspheres were respectively obtained in the same manner as in Production Example 1, except that various components and amounts used in the polymerization step of Production Example 1 were changed to those shown in Table 1. Table 1 shows the physical properties of the obtained microspheres.

[0148] The heat-expandable microspheres obtained in Production Examples 1 to 4 above were referred to as microspheres (1) to (4), respectively.

[0149] [Table 1]

[0150]

Embodiment 1

[0152] (masterbatch)

[0153] Using a pressurized kneader with a capacity of 10 L, ethylene-ethyl acrylate copolymer (manufactured by Dow Chemical Japan Co., Ltd., NUC-6070, melt flow rate 250 g / 10 min, melting point 87 ° C, ethylene content rate 75 % by weight, true specific gravity 0.94, tensile failure stress 5MPa) 2.4kg melt-kneaded, when the kneading temperature reached 95°C, mixed with 5.6kg of heat-expandable microspheres obtained in Production Example 1 and uniformly mixed to make a premix . The discharge amount of the premix from the pressurized kneader was measured, and the discharge performance (handling performance) at the time of masterbatch production was evaluated based on the evaluation criteria shown below. As a result, good discharge performance was confirmed. The results are shown in Table 2.

[0154] Then, the obtained premix was supplied to a twin-screw extruder with a barrel diameter of 40 mm, and extruded at an extrusion temperature of 90° C. to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com