Processing method for egg product

A processing method and technology for egg products, which are applied in food preparation, application, food science and other directions, can solve the problems of large damage to nutrients, slow drying speed, and high production costs, and achieve the effect of increasing and maintaining nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

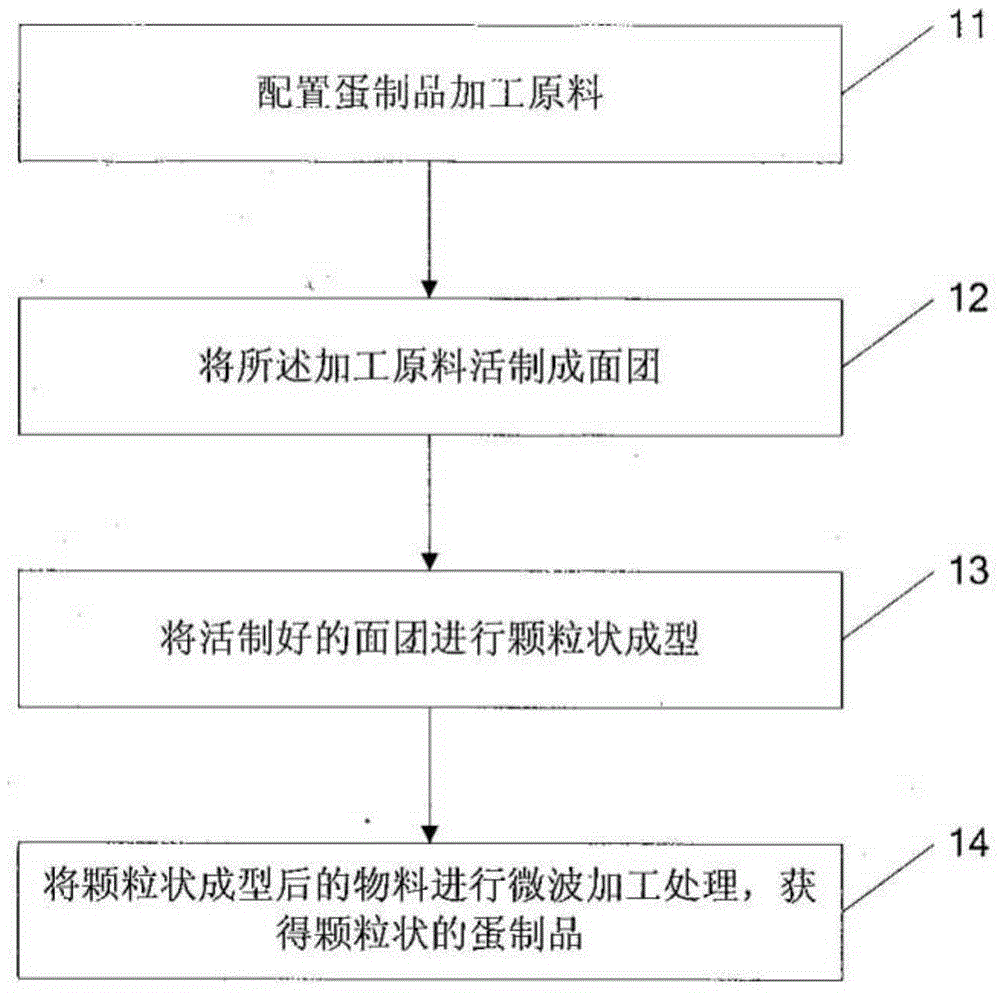

[0023] Such as figure 1 Shown, the processing method of the egg product of the embodiment of the present invention 1 comprises the steps:

[0024] Step 11: Prepare egg product processing raw materials, the processing raw materials include: egg powder or egg liquid, starch, edible oil, seasoning, water, wherein, the dry matter of egg powder or egg liquid accounts for 20% of the total weight of the processing raw materials -50%, starch accounts for 10%-30% of the total weight of the processed raw materials, edible oil accounts for 2% of the total weight of the processed raw materials, seasonings account for 20% of the total weight of the processed raw materials, and water accounts for the total weight of the processed raw materials 18% of the total weight of raw materials.

[0025] Among them, various raw materials need to be accurately weighed. Preferably, the dry matter of the egg powder or egg liquid accounts for 35%-45% of the total weight of the processed raw materials, w...

Embodiment 2

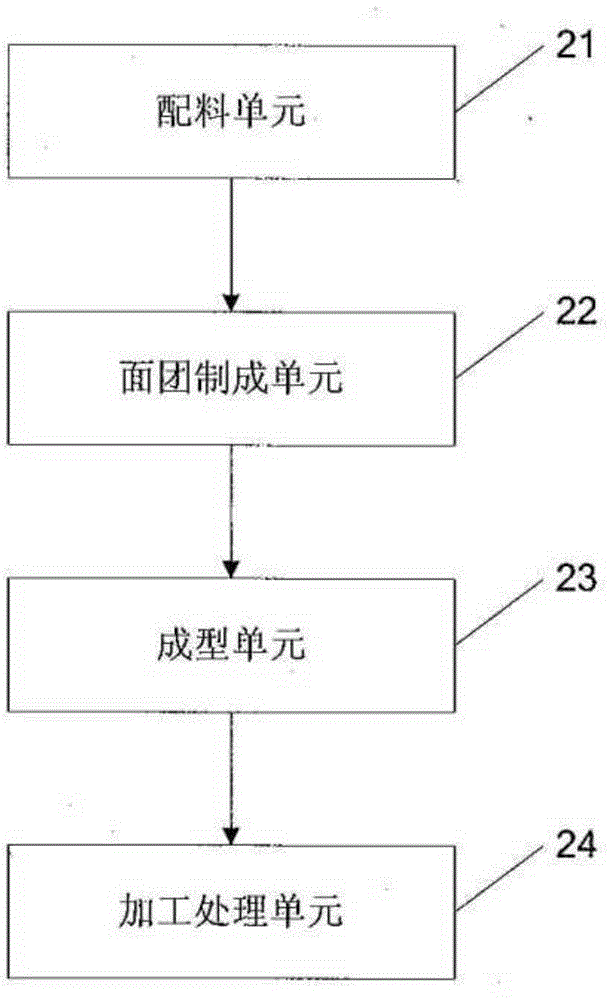

[0038] Such as figure 2 Shown, the processing device of the egg product of the embodiment of the present invention 2 comprises:

[0039] The batching unit 21 is used to mix straight egg product processing raw materials, and the processing raw materials include: egg powder or egg liquid, starch, edible oil, seasoning, water, wherein, the dry matter of egg powder or egg liquid accounts for the total of the processing raw materials. 20%-50% by weight, starch accounts for 10%-30% of the total weight of the processed raw materials, edible oil accounts for 2% of the total weight of the processed raw materials, seasonings account for 20% of the total weight of the processed raw materials, water Accounting for 18% of the total weight of the processed raw materials;

[0040] Dough making unit 22, which is used to stir the processed raw materials obtained by said batching unit 21 into dough;

[0041] The forming unit 23 is used for forming the dough stirred by the dough making unit 2...

Embodiment 3

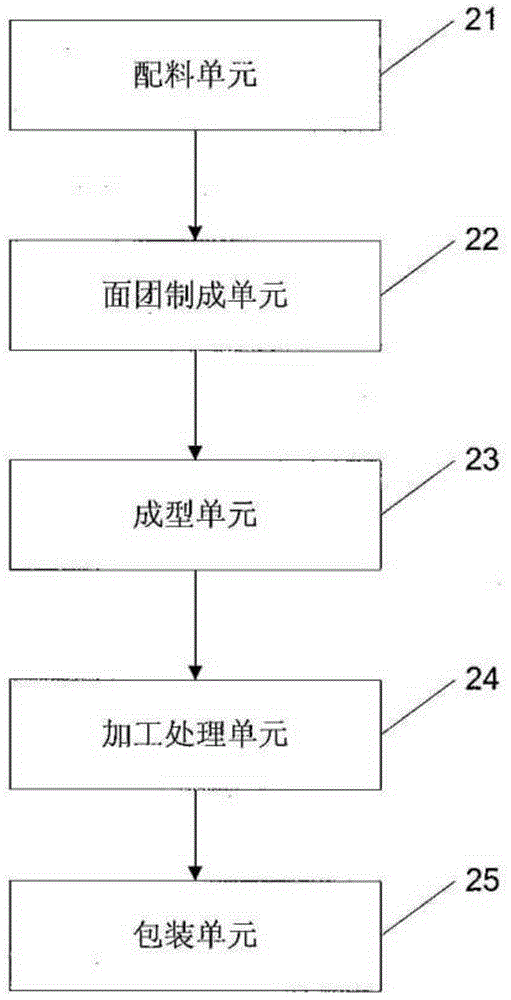

[0046] If the product is sold, such as image 3 As shown, on the basis of the processing device in Embodiment 2, the egg product processing device of the present invention may further include a packaging unit 25 for containing the finished egg product. During the packaging process, the food used in the inner packaging is heat-sealed with two layers of plastic packaging bags to prevent the dry product from absorbing moisture; the outer packaging should use high-strength corrugated boxes to prevent the product from being affected by external extrusion.

[0047]Wherein in the embodiment of the invention, egg powder or egg liquid includes but not limited to egg powder or egg liquid made from chicken eggs, duck eggs, goose eggs and other poultry eggs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com