Rim-control type electric bike and drive, brake and range extending methods thereof

A technology for electric vehicles and rims, which is applied in the control of driving, electric vehicles, motor vehicles, etc., can solve the problems of unrealistic continuation mileage, short continuation mileage, and restrictions, and achieves overcoming short continuation mileage and diversified combinations. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

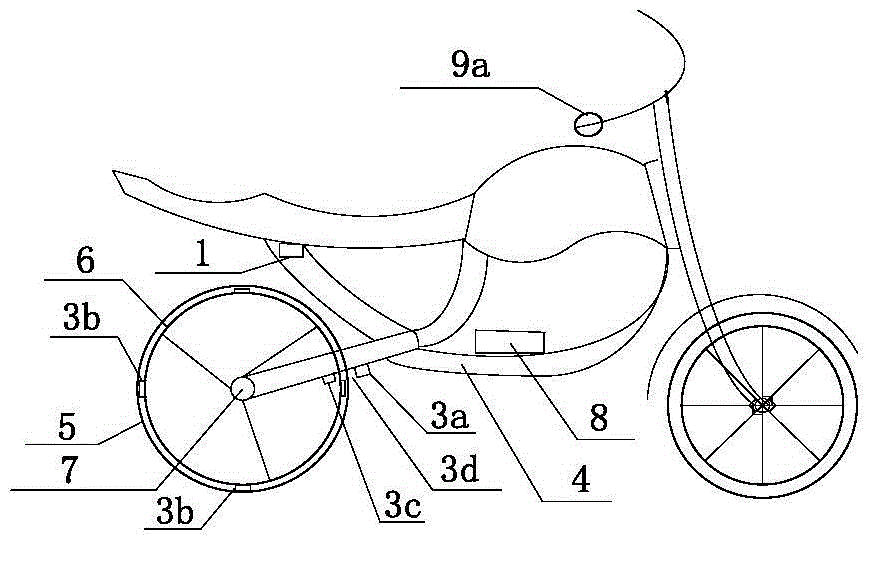

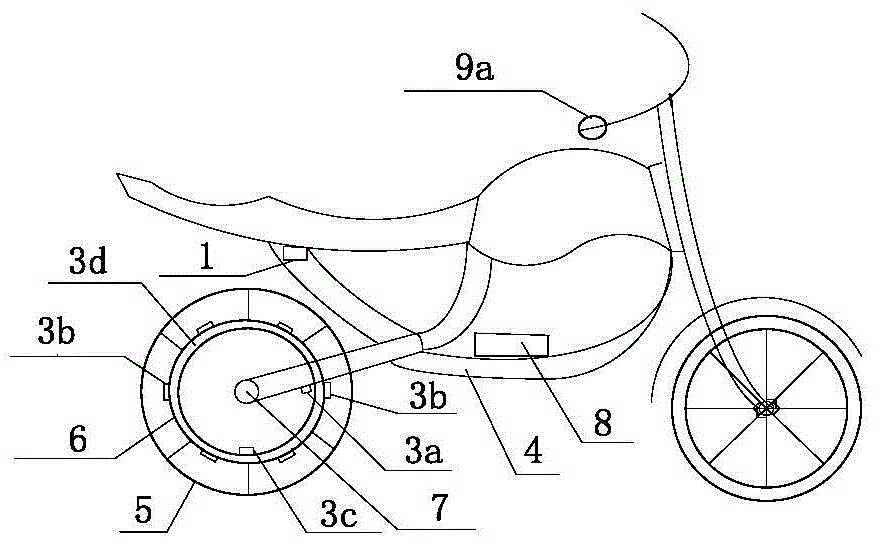

[0092] An electric two-wheeled vehicle with a front and rear two-wheel structure. Figure 1a The frame 4 shown is a wheel 5 with a circumference of 1000mm. The electric device is designed as a combination of a stator unit 3a and eight permanent magnet rotor units 3b on the rim 6. The rotor unit is arranged on the outer edge of the rim, and the stator unit is installed On the frame at the inner edge of the rear wheel.

[0093] The battery pack is made of 24V10Ah lithium iron phosphate battery, which is installed in a special place in the frame.

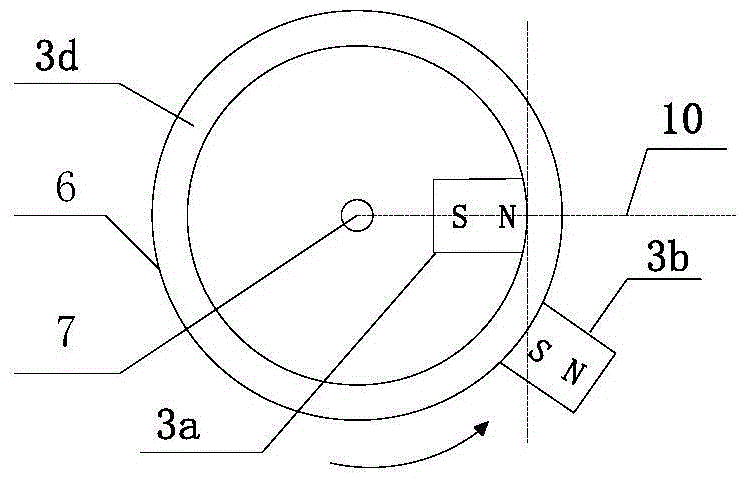

[0094] The length of the permanent magnet rotor unit 3b is 20mm, and the width takes the maximum value without affecting the outer rubber wheel of the rim. It is tightly installed on the outer edge of the rim 6 made of titanium-aluminum alloy. The tangent lines of the circles are parallel, and the S poles of the eight rotor units all face the direction of rotation of the wheel 5; the stator unit core material is a concave ferromagnet t...

Embodiment 2

[0102] Embodiment 1 is provided with an electromagnetic brake function.

[0103] The electromagnetic braking device 9b is a ten-stage rheostat, and the power modulator correspondingly adds a braking signal input terminal 1e to be electrically connected with the electromagnetic braking device, such as Figure 5c shown. The braking logic of the power modulator is: when the manual control electromagnetic brake device sends out a braking signal, the power modulator cuts off the T 1 corresponding to the timing current while starting T 2 time domain power-up, the T 2 The time domain is set as the time period when the sensing unit 3c senses the rotor unit 3b around the axis to the position where θ is from 30 degrees to θ is 0 degrees. The braking current output by the power modulator corresponds to the ten-level resistance setting of the electromagnetic braking device as ten-level intensity, and the output current intensity is set as: the first level is 6A, the last level is 12A, ...

Embodiment 3

[0106] The braking logic of Embodiment 2 is further optimized as follows: the power modulator starts T 2 While powering up in the time domain, the T 0 part of the time domain operating logic is synchronously transformed for power-up, the T 0 Part of the time domain value and (T 1 +T 2 ) are equal, T 0 The moment of energization starts when θ is 0; the power modulator starts at this T 0 The intensity of the braking current output in part of the time domain and T 2 Same time domain. In this embodiment, the time-domain energization of the rotor unit away from the state of the stator unit is added, and the electromagnetic braking / braking effect of the electric device is strengthened, and the corresponding period sequence can be briefly set as: in (T 1 +T 2 +T 0 ) timing, the initial 1 / 3 of T 1 time domain power down, after 2 / 3 of (T 2 +T 0 ) time domain energization. .

[0107] In this embodiment, the winding of the stator unit is changed to a double-wire winding core...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com