Preparation method of low-odor oil-extended styrene butadiene rubber

An oil-extended styrene-butadiene rubber and low-odor technology, which is applied in the field of synthetic rubber production, can solve problems such as unpleasantness, toxicity of mercaptans, and strong odor of mercaptans, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) First, vacuum and nitrogen replacement are carried out to the polymerization kettle. Add soft water, emulsifier, electrolyte solution, reducing agent, environment-friendly regulator, styrene, butadiene, and isoprene to the polymerization kettle in turn. When the temperature of the polymerization kettle drops to 5°C, add the initiator to peroxidize Hydrogen is used for menthane, and the polymerization experiment is carried out. When the conversion rate reaches 60%, the terminator HSD is added to terminate the reaction, and the oil-extended rubber base glue is obtained.

[0024] (2) Mix the oil-extended adhesive base glue and the extended oil emulsion evenly, add it to the dilute sulfuric acid solution with a pH value of 3, stir, and control the temperature at 55°C for 5 minutes. After coagulation, wash and dry to obtain the filled Finished oil glue.

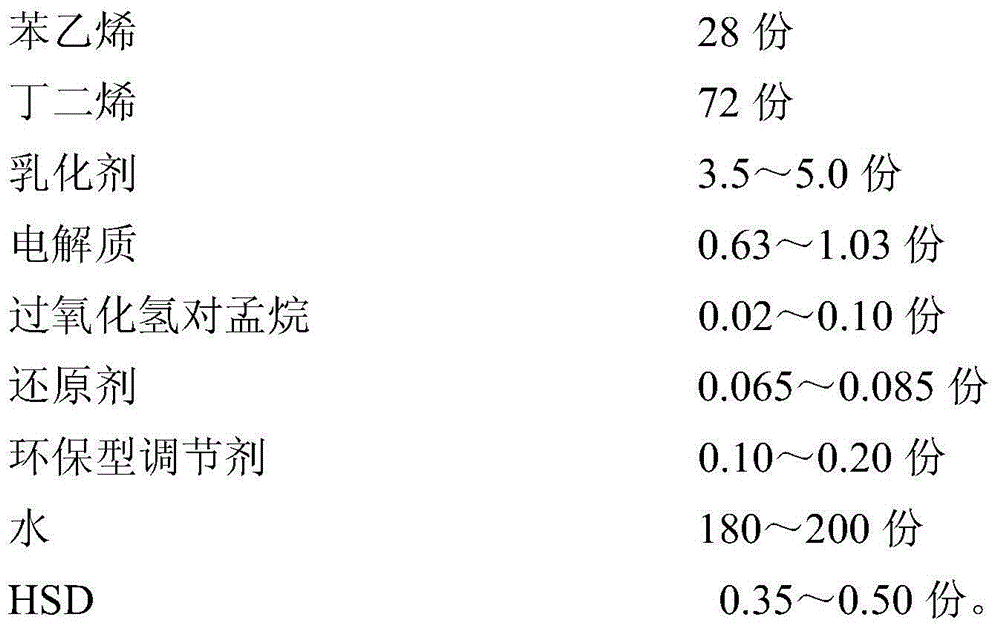

[0025] The polymerization component and parts by weight that above-mentioned step (1) comprises are:

[0026]

...

Embodiment 2

[0044] (1) First, vacuum and nitrogen replacement are carried out to the polymerization kettle. Add soft water, emulsifier, electrolyte solution, reducing agent, environment-friendly regulator, styrene, butadiene, and isoprene to the polymerization kettle in turn. When the temperature of the polymerization kettle drops to 5°C, add the initiator to peroxidize Hydrogen is used for menthane, and the polymerization experiment is carried out. When the conversion rate reaches 60%, the terminator HSD is added to terminate the reaction, and the oil-extended rubber base glue is obtained.

[0045] (2) Mix the oil-extended adhesive base glue and the extended oil emulsion evenly, add it to the dilute sulfuric acid solution with a pH value of 4, stir, and control the temperature at 65°C for 10 minutes. After coagulation, wash and dry to obtain the filled Finished oil glue.

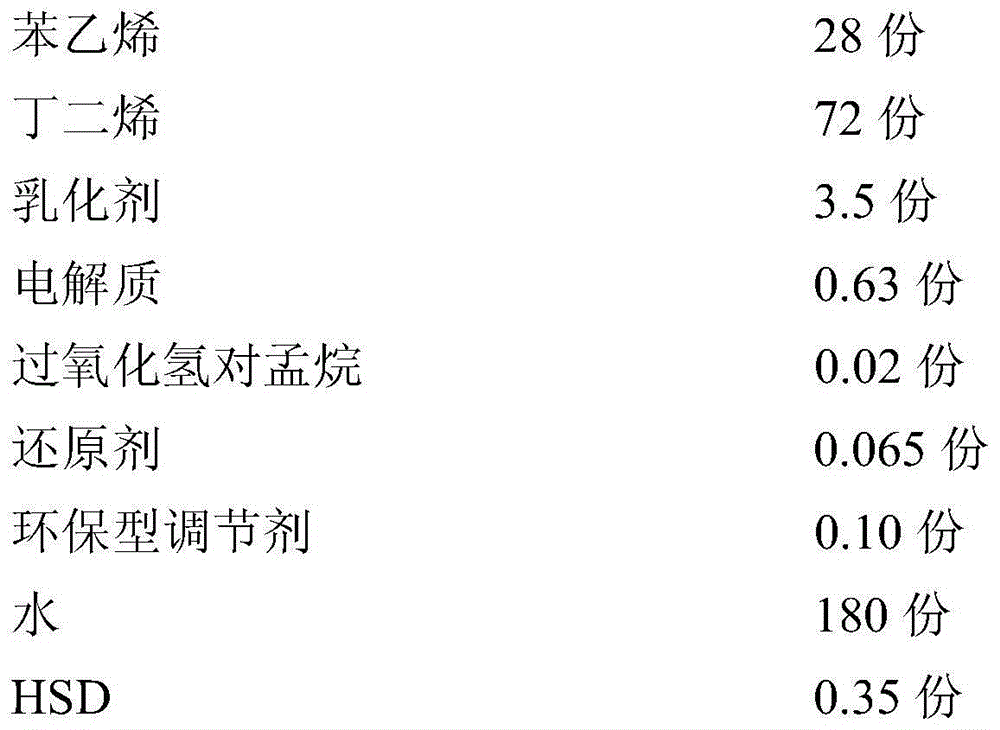

[0046] The polymerization component and parts by weight that above-mentioned step (1) comprises are:

[0047]

...

Embodiment 3

[0065] (1) First, vacuum and nitrogen replacement are carried out to the polymerization kettle. Add soft water, emulsifier, electrolyte solution, reducing agent, environment-friendly regulator, styrene, butadiene, and isoprene to the polymerization kettle in turn. When the temperature of the polymerization kettle drops to 5°C, add the initiator to peroxidize Hydrogen is used for menthane, and the polymerization experiment is carried out. When the conversion rate reaches 60%, the terminator HSD is added to terminate the reaction, and the oil-extended rubber base glue is obtained.

[0066] (2) Mix the oil-extended adhesive base glue and the extended oil emulsion evenly, add it to the dilute sulfuric acid solution with a pH value of 3.5, stir, and control the temperature at 60°C for 7.5 minutes. After coagulation, wash and dry to obtain the filled Finished oil glue.

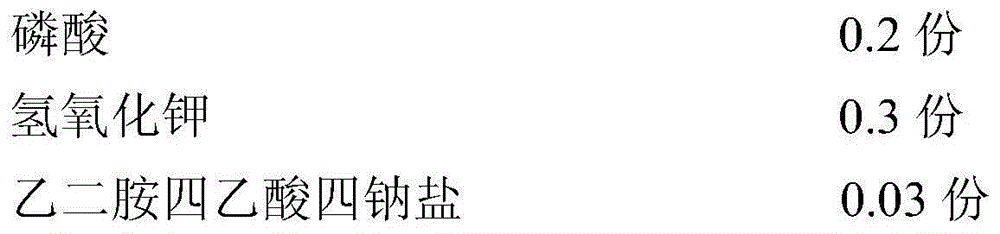

[0067] The polymerization component and parts by weight that above-mentioned step (1) comprises are:

[0068] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com