Preparing method for diesel oil lubricity improver

A lubricity and improver technology is applied in the field of preparation of diesel lubricity additives, which can solve the problems of reducing the lubricating ability of the engine injection system, reducing the lubricity of diesel oil, damage, etc., and achieving strong lubricating ability, improving lubricity and good lubricating ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

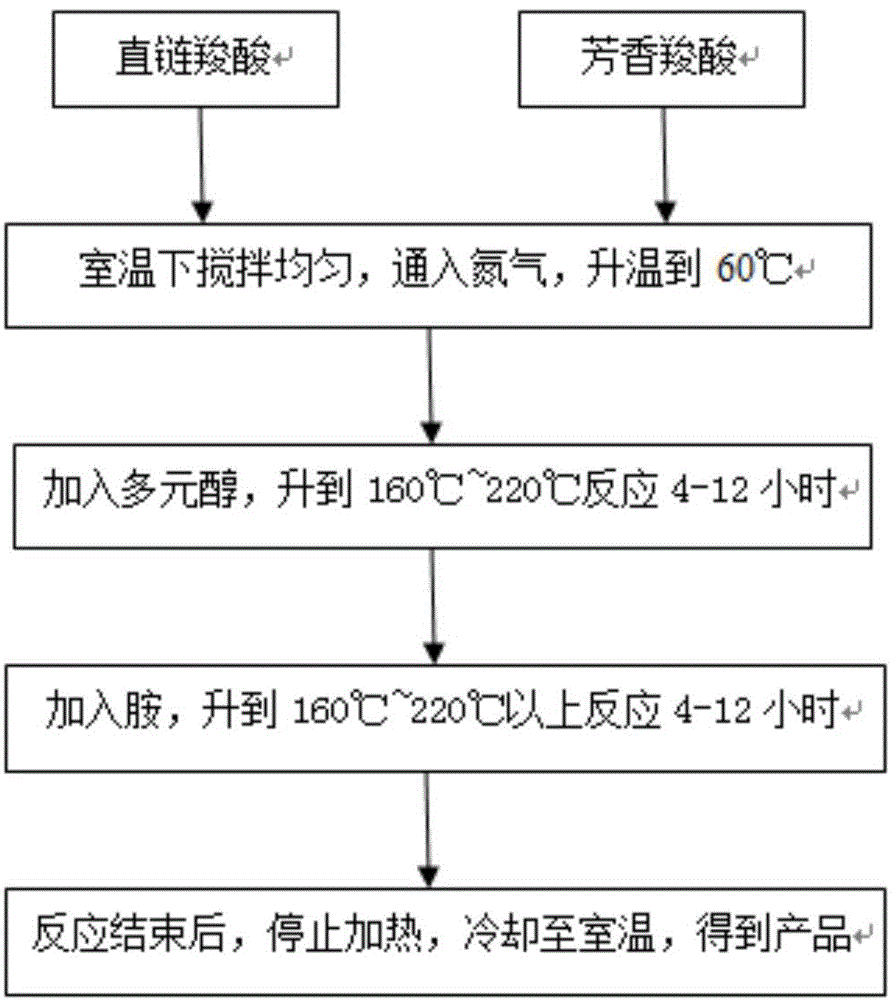

Method used

Image

Examples

preparation example Construction

[0030] The dosage of each raw material in the preparation method of diesel lubricity improver:

[0031] In the present invention, the amount of each raw material used in the preparation method of the diesel lubricity improver is not particularly limited, usually in parts by weight, 100 parts of linear carboxylic acid, 2 to 100 parts of aromatic carboxylic acid, 2 to 100 parts of polyol 20 parts, 2-20 parts of amine; preferably, in parts by weight, 100 parts of linear carboxylic acid, 5-50 parts of aromatic carboxylic acid, 5-15 parts of polyol, and 5-15 parts of amine.

[0032] If the amount of aromatic carboxylic acid is less than 2 parts, the lubricating performance of the product will be deteriorated due to too little amount of aromatic carboxylic acid, while if the amount of aromatic carboxylic acid is more than 100 parts, the low-temperature fluidity of the product will be deteriorated due to the excessive amount of aromatic carboxylic acid. Nothing else works.

[0033...

Embodiment 1

[0044] Add 80 parts of linoleic acid and 20 parts of cinnamic acid to the reaction kettle, stir and mix at room temperature, feed nitrogen, and heat slowly, when the reaction temperature rises to 60 ° C, add 8 parts of ethylene glycol, and react at 180 ° C After 6 hours, 6 parts of diethanolamine were added, and the reaction was continued at 180° C. for 4 hours. After the reaction was completed, the heating was stopped, and after cooling to room temperature, a liquid diesel oil lubricity improver was obtained.

Embodiment 2

[0046] Add 90 parts of linoleic acid and 10 parts of cinnamic acid to the reaction kettle, stir and mix evenly at room temperature, introduce nitrogen, slowly heat, when the reaction temperature rises to 60 ° C, add 8 parts of glycerol, and react at 200 ° C After 6 hours, 6 parts of diethanolamine were added, and the reaction was continued at 200° C. for 4 hours. After the reaction was completed, the heating was stopped, and after cooling to room temperature, a liquid diesel oil lubricity improver was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com