Corrosion-resisting and anti-dry-grinding magnetic axially split pump

An anti-dry wear, anti-corrosion technology, used in pumps for special fluids, components of pumping devices for elastic fluids, pumps, etc. Large problems, to achieve the effect of expanding applicability, improving work efficiency, and reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

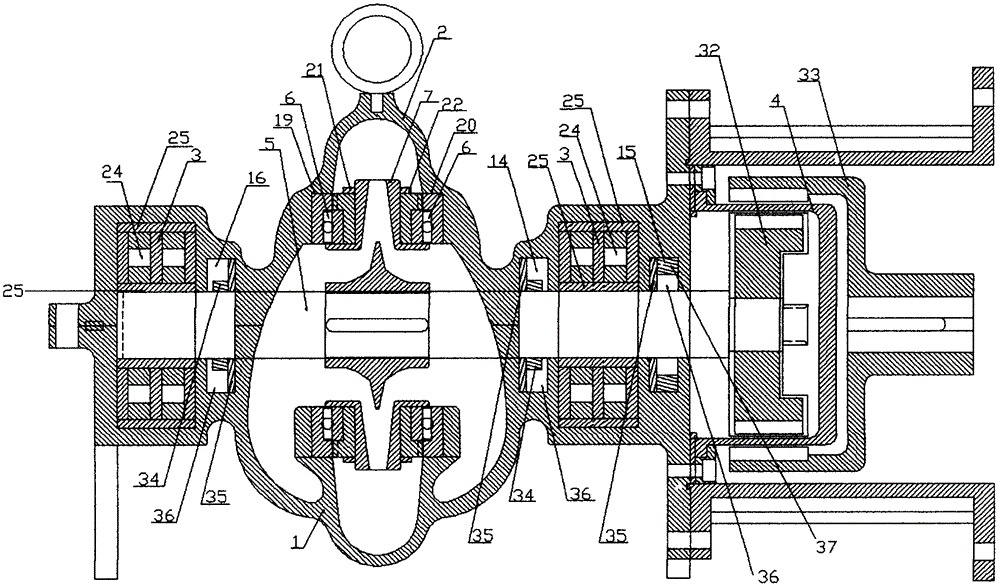

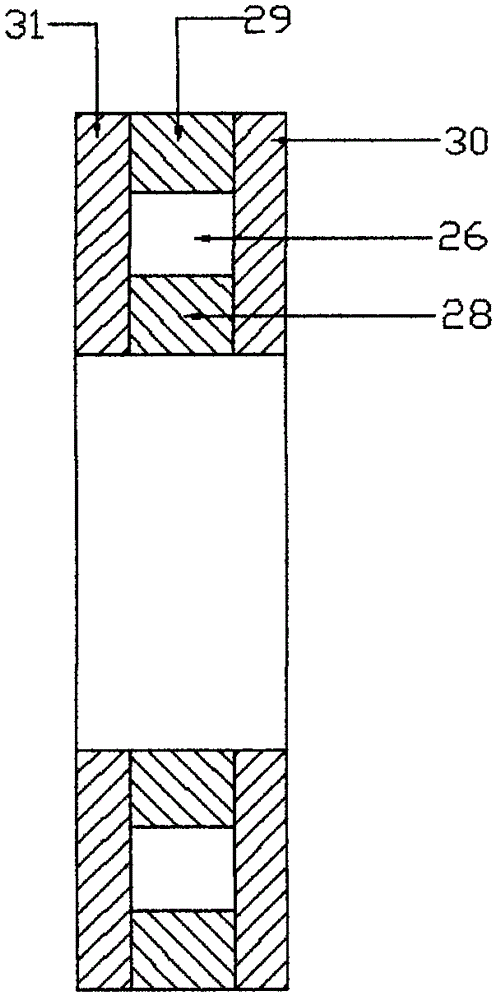

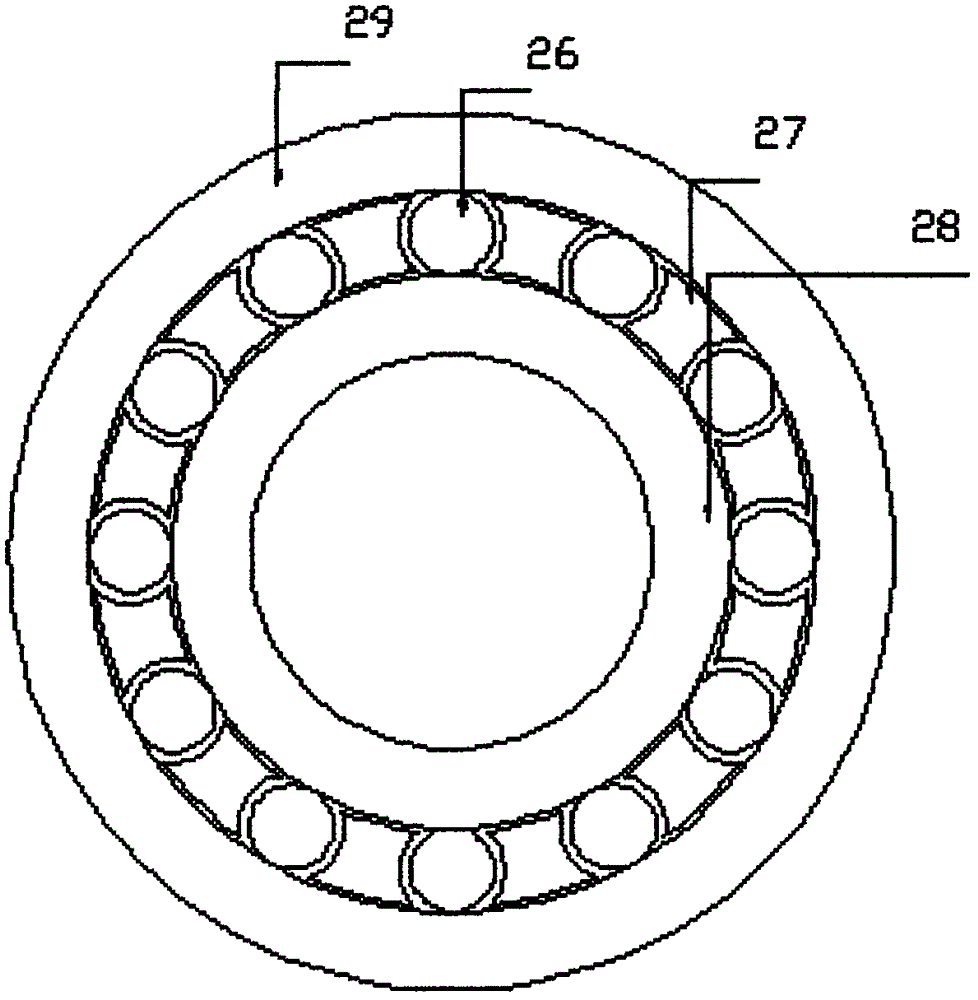

[0019]Embodiment: A kind of anti-corrosion and anti-dry wear magnetic split pump, including bearing 5, pump body 1, pump cover 2, bearing component 3, sealing ring 6, impeller 7, inner magnetic rotor 32, outer magnetic rotor 33, isolation Sleeve 4, anti-corrosion filter parts 14, 15, 16, the impeller 7 and the pump shaft 5 are installed in the pump cavity through the key and the keyway, placed between the driving end and the non-driving end of the pump shaft 5, the outside of the impeller 7 and the pump A sealing ring 6 is provided between the inner walls of the cavity, the inner magnetic rotor 32 is installed at the end of the driving end of the pump shaft 5, the outer magnetic rotor 33 is installed at the motor shaft end, and an isolation sleeve 4 is arranged between the inner magnetic rotor 32 and the outer magnetic rotor 33 to isolate The sleeve 4 is sealed and fixedly connected with the pump body 1 and the pump cover 2. The pump body 1, the pump cover 2 and the spacer slee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap