Engine device

A technology of engine and exhaust gas purification device, which is applied in the direction of power plant, engine components, combustion engine, etc., can solve the problem that the DPF box or SCR box cannot be compactly supported, and achieve the effect of improving maintenance workability and suppressing the cost of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

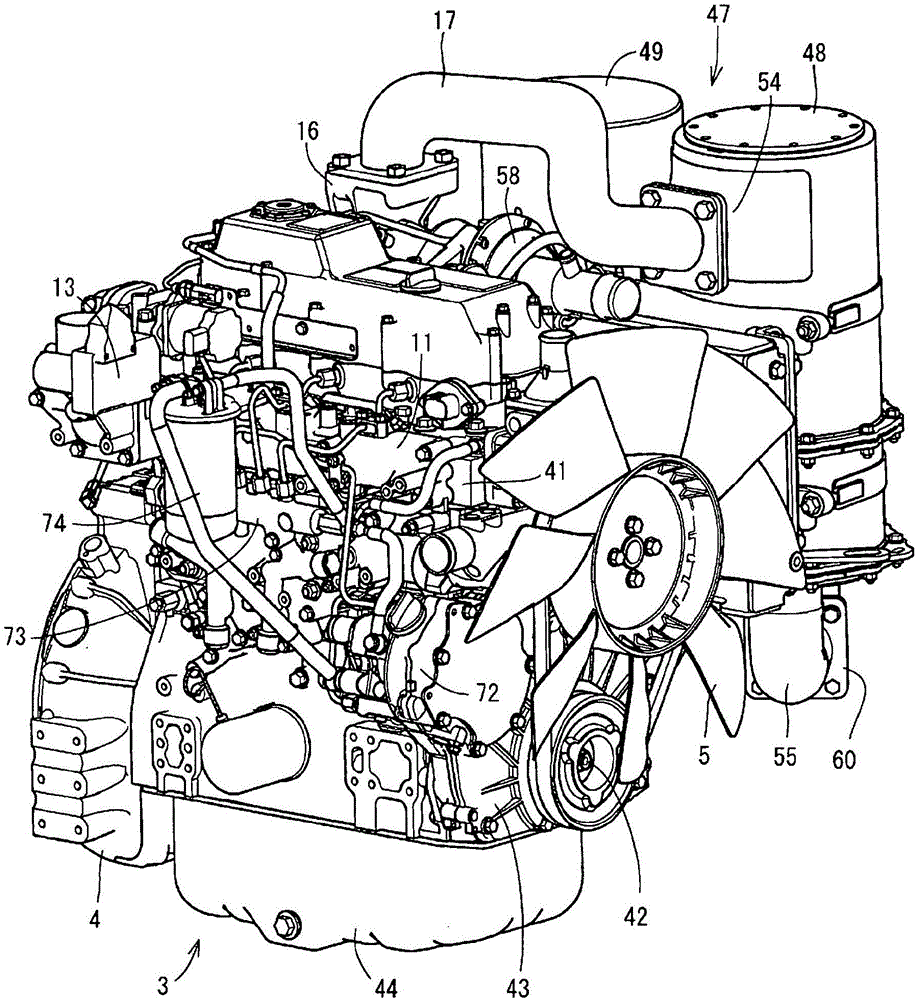

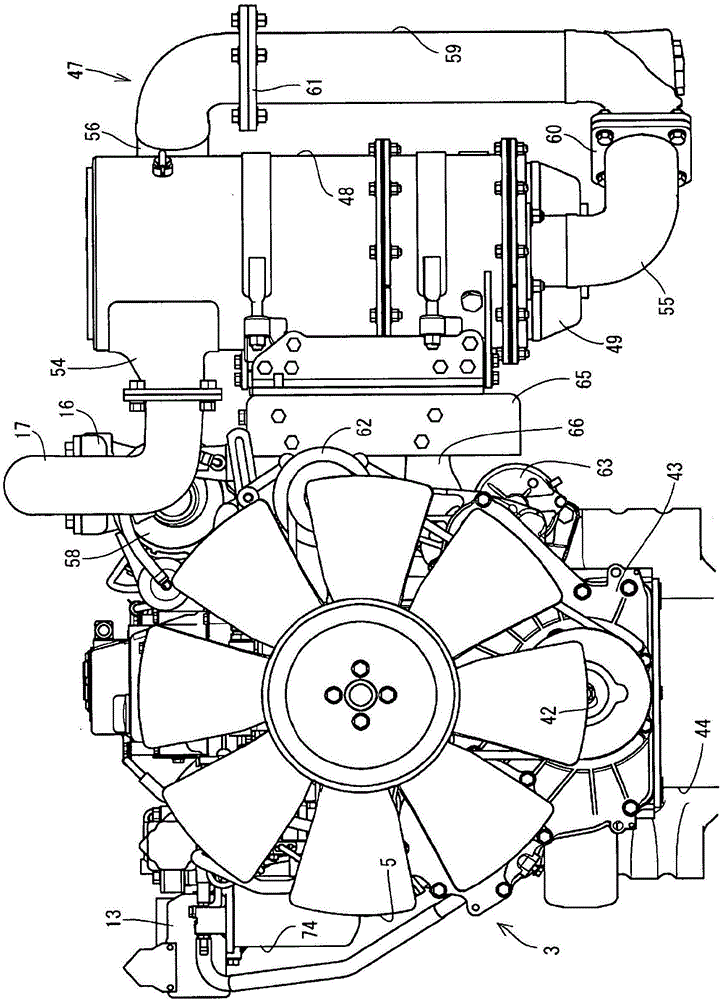

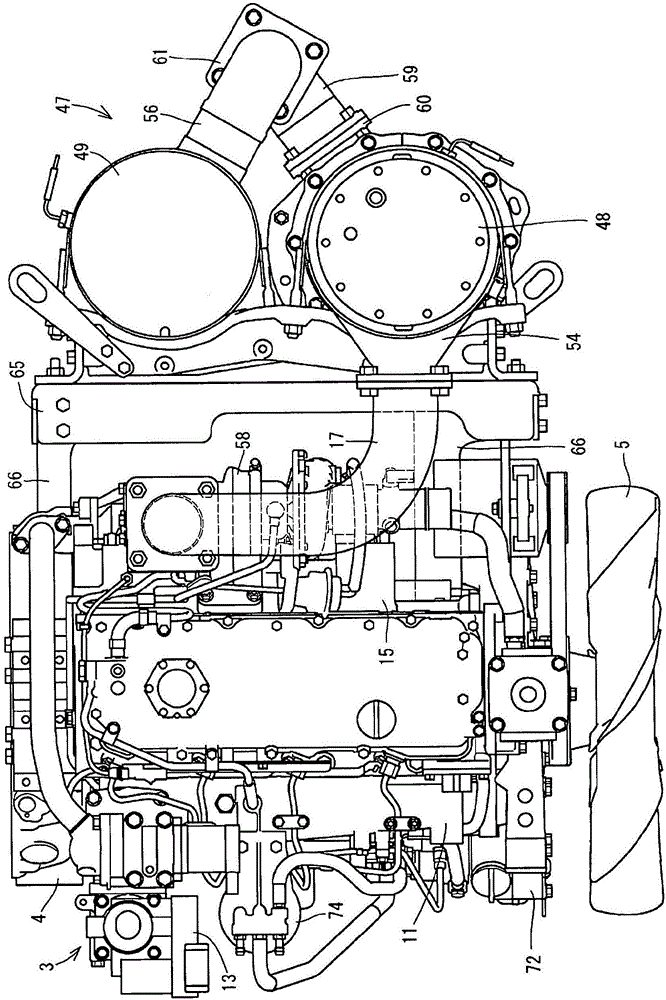

[0051] Below, refer to Figure 1 to Figure 6 , the first embodiment of the engine device of the present invention will be described based on the drawings. Figure 1 ~ Figure 3 It is an explanatory diagram showing the diesel engine of the first embodiment, Figure 4 ~ Figure 6 It is an explanatory diagram of a stationary power generation working machine 70 equipped with the above-mentioned diesel engine and generator.

[0052] refer to Figure 4 ~ Figure 6 , the structure of the stationary power generation working machine 70 of the first embodiment will be described. Such as Figure 4 ~ Figure 6 As shown, a square box-shaped casing 2 is placed on the casing platform 1 . A diesel engine 3 is arranged in the center of the inside of the casing 2 on the upper surface of the machine frame platform 1 . The radiator 6 is arranged on the side where the cooling fan 5 is installed on the front side of the diesel engine 3 . A generator 18 , which will be described later, is disposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com