Cutter-inverted fresh lotus seed shelling machine and application method thereof

An upside-down, shelling machine technology, applied in the field of agricultural machinery, can solve the problems of easy damage, short conveyor belt life, low reliability, etc., and achieve the effects of wide market demand, improved cutting effect, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

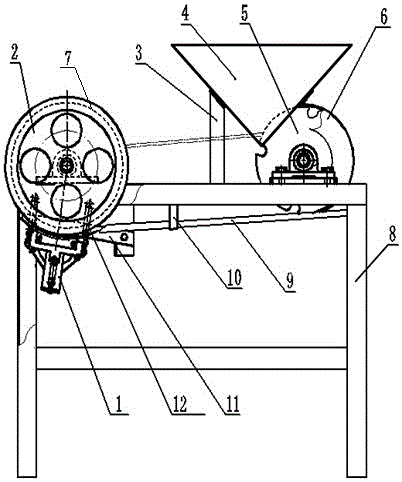

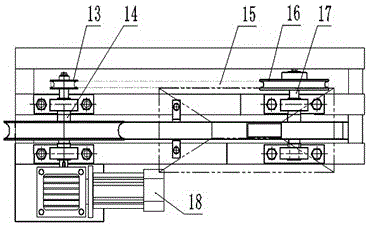

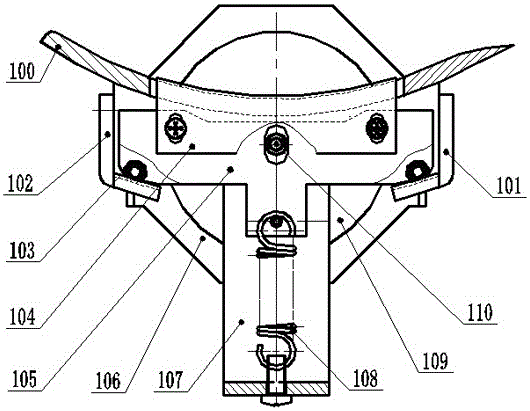

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0029] Such as Figure 1~5 As shown, a kind of cutter inverted type fresh lotus seed peeling machine of the present embodiment comprises a frame 8, and a hopper 4 for inputting fresh lotus seeds is vertically provided with a support frame 3 on the said frame 8, so The lower side of the hopper 4 is provided with a discharge port, and the discharge port is connected with a discharge mechanism for grading and discharging; the bottom of the discharge mechanism is connected with an obliquely arranged rolling groove for conveying fresh lotus seeds. 9. The upper end of the rolling groove 9 is engaged with the discharge mechanism, and the lower end extends downward to the bottom of a sheave 2, and the outer circumference of the sheave 2 is provided with a groove 7 along the circumferential direction; it also includes a groove for cutting The lotus see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com