3D printing-based capsule contracture-preventive breast prosthesis manufacturing method and breast prosthesis

A technology of capsular contracture and 3D printing, applied in prosthesis, fake breast, medical science, etc., can solve problems such as capsular contracture, reduce the formation of capsular contracture, reduce the incidence of capsular contracture, and prevent excessive proliferation of fibroblasts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

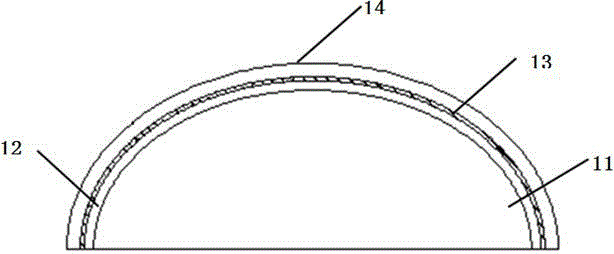

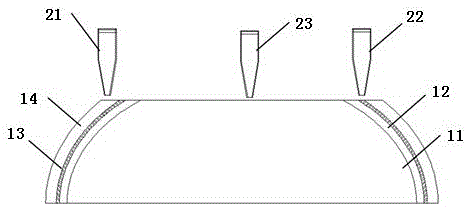

[0022] The specific embodiments of the present application will be described in further detail below with reference to the accompanying drawings.

[0023] The purpose of this application is to provide a method for making a breast prosthesis and a breast prosthesis for preventing capsular contracture based on 3D printing, so as to solve the problem that a capsule will be formed after the existing breast prosthesis is implanted into the human body, and the capsular contracture will cause the capsule that accommodates the prosthesis. The cavity shrinks and the prosthesis is compressed and deformed.

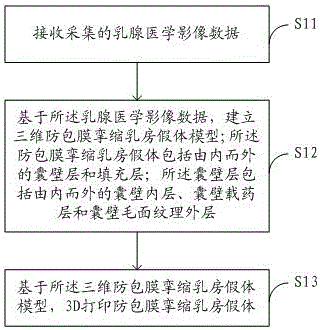

[0024] like figure 1 As shown, the method for making a capsular contracture-resistant breast prosthesis based on 3D printing proposed in this application includes the following steps:

[0025] Step S11: Receive the collected breast medical image data:.

[0026] The breast imaging data of the patient is collected, and the size and shape of the breast prosthesis required for the pati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com