Linalool distillation extraction device and technology

A distillation device and linalool technology, applied in steam distillation, separation/purification of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as low efficiency, cumbersome process, and long distillation time, so as to improve production efficiency and increase Distillation efficiency and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

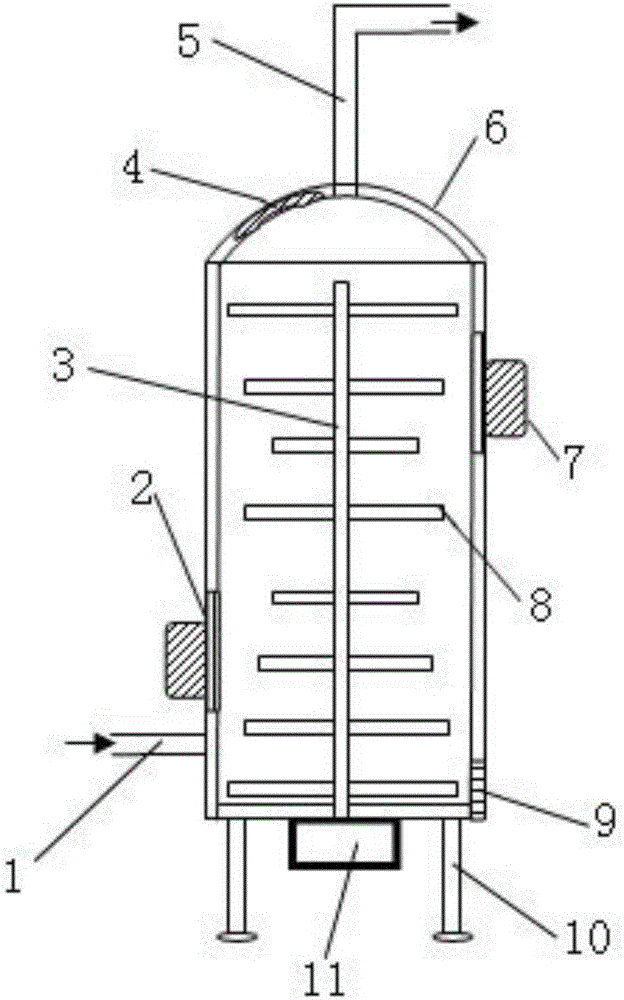

[0049] Such as figure 1 Shown, a kind of linalool distillation extraction device comprises central axis 3, housing 6 and motor 11,

[0050] One side of the bottom of the housing 6 is provided with a steam inlet pipe 1, and the other side of the bottom of the housing 6 is provided with a discharge port 9,

[0051] The top of the housing 6 is provided with a material inlet 4, and the top of the housing 6 is provided with a steam outlet pipe 5,

[0052] A glass panel 2 is provided on both sides of the housing 6, and the two glass panels 2 are arranged diagonally. A microwave transmitter 7 is welded on the outside of the glass panel 2.

[0053] The middle part of the inner cavity of the distillation extraction device is provided with a central shaft 3, and the central shaft 3 is provided with a plurality of metal impellers 8,

[0054] The bottom of the housing 6 is provided with a bracket 10 and a motor 11 , and the motor 11 is connected to the central shaft 3 in transmission. ...

specific Embodiment 2

[0075] A linalool distillation extraction device, comprising a central shaft 3, a housing 6 and a motor 11,

[0076] One side of the bottom of the housing 6 is provided with a steam inlet pipe 1, and the other side of the bottom of the housing 6 is provided with a discharge port 9,

[0077] The top of the housing 6 is provided with a material inlet 4, and the top of the housing 6 is provided with a steam outlet pipe 5,

[0078] A glass panel 2 is provided on both sides of the housing 6, and the two glass panels 2 are arranged diagonally. A microwave transmitter 7 is welded on the outside of the glass panel 2.

[0079] The middle part of the inner cavity of the distillation extraction device is provided with a central shaft 3, and the central shaft 3 is provided with a plurality of metal impellers 8,

[0080] The bottom of the housing 6 is provided with a bracket 10 and a motor 11 , and the motor 11 is connected to the central shaft 3 in transmission.

[0081] A kind of linal...

specific Embodiment 3

[0100] A linalool distillation extraction device, comprising a central shaft 3, a housing 6 and a motor 11,

[0101] One side of the bottom of the housing 6 is provided with a steam inlet pipe 1, and the other side of the bottom of the housing 6 is provided with a discharge port 9,

[0102] The top of the housing 6 is provided with a material inlet 4, and the top of the housing 6 is provided with a steam outlet pipe 5,

[0103] A glass panel 2 is provided on both sides of the housing 6, and the two glass panels 2 are arranged diagonally. A microwave transmitter 7 is welded on the outside of the glass panel 2.

[0104] The middle part of the inner cavity of the distillation extraction device is provided with a central shaft 3, and the central shaft 3 is provided with a plurality of metal impellers 8,

[0105] The bottom of the housing 6 is provided with a bracket 10 and a motor 11 , and the motor 11 is connected to the central shaft 3 in transmission.

[0106] A kind of linal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com