Novel ball-milling method used for magnetic material industry

A magnetic material and ball milling technology, applied in grain processing, etc., can solve the problems affecting the particle size of the final material, affecting the grinding efficiency, uneven unevenness, and achieve the effects of high grinding efficiency, reduced pollution, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

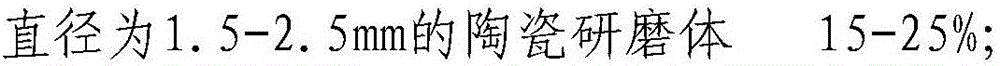

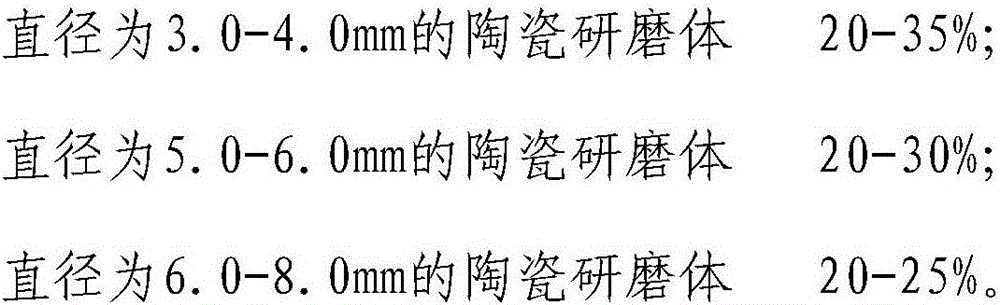

[0024] According to a novel ball milling method used in the magnetic material industry provided by the present invention, the grinding medium and the material to be ground are added to the ball milling equipment, and the material to be ground is ground to a specified particle size (or fineness) through the action of the grinding medium . The material to be ground is a magnetic material, such as iron alloy, nickel alloy, cobalt alloy and the like. The grinding medium is selected to have a Mohs hardness of 7-9 and a density of 3.0-6.0g / cm 3 ceramic grinding body.

[0025] Preferably, the grinding medium can be selected to have a Mohs hardness greater than 8 and less than or equal to 9, and a density of 3.0-4.5g / cm 3 ceramic grinding body.

[0026] As a further preference, the grinding medium can also be selected to have a Mohs hardness greater than 8 and less than or equal to 9, and a density of 3.5-4.0g / cm 3 ceramic grinding body.

[0027] The ceramic grinding body can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com