3D printing integrated preparation method for metal dies of gradient materials

A metal mold and 3D printing technology, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency, can solve problems such as difficulty in achieving continuous and uniform changes in material components, waste of precious element usage, and cumbersome preparation processes, etc., to achieve The effect of shortening the preparation cycle, reducing the preparation cost and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

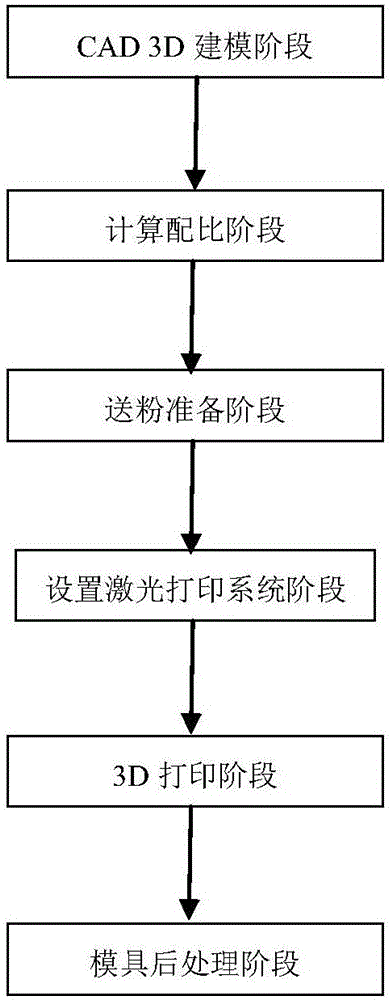

[0023] Attached below figure 1 An integrated preparation method for 3D printing of a gradient material metal mold according to the present invention will be described in detail.

[0024] An integrated preparation method for gradient material metal mold 3D printing, the preparation method comprising the following steps:

[0025] 1) CAD 3D modeling stage: The industrial computer on the workbench has built-in CAD 3D modeling software and establishes a 3D model diagram, and performs layered slice processing on the established mold 3D model diagram to obtain the material component information and slice of each slice The surrounding contour trajectory of the slice, wherein the thickness of the layered slice is 10-100 μm; according to the material component information of each slice and the surrounding contour trace information of the slice, the scanning path of the laser printing system and the powder feeder is generated;

[0026] 2) Calculation ratio stage: The industrial computer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com