A weather-resistant submerged arc welding wire for coating-free weather-resistant steel bridges

A technology of submerged arc welding wire and weathering steel, applied in arc welding equipment, welding medium, welding equipment, etc., can solve problems such as poor weather resistance, achieve uniform droplet transfer, excellent metallurgical quality, and easy rolling and wire drawing processes effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

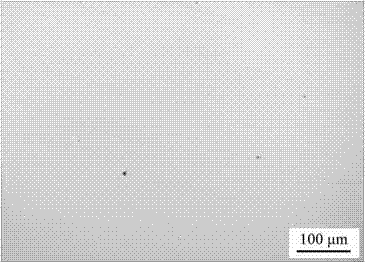

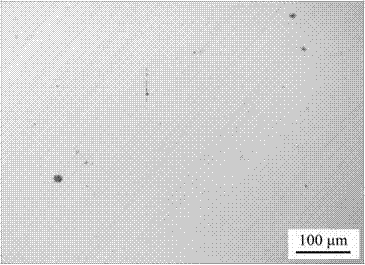

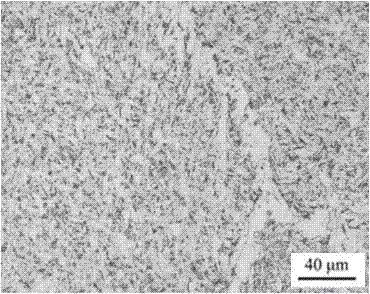

[0032] The invention provides a weather-resistant submerged-arc welding wire for a weather-resistant steel bridge without coating. The chemical composition distribution example is shown in Table 1. According to the accurately calculated welding wire composition distribution ratio, raw materials with low P, S, gas and inclusion content are selected. Calculate the amount of alloy added, use a 50Kg vacuum induction furnace to smelt the steel for welding wire, after charging, melting, and refining, add active element alloys such as Ca and Re in the alloying stage, and cast it into steel ingots after the composition is qualified. After the steel ingot is forged into a billet, it is rolled into a Φ5.5mm wire rod. After the wire rod is shelled, cleaned, electrolytic pickling, cleaned and boronized, it is then rough-drawn and fine-drawn to make a Φ2.0-5.0mm wire rod. Welding wire, the quality of welding wire is stable, and the electroless copper plating method is used to plate copper o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com