Solid solution strengthened heat-resistant alloy c-hra-2 welding wire for argon arc welding

A C-HRA-2, heat-resistant alloy technology, applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problems of poor matching of chemical composition and mechanical properties of deposited metal, and achieve excellent welding process performance. Good physical and weld formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

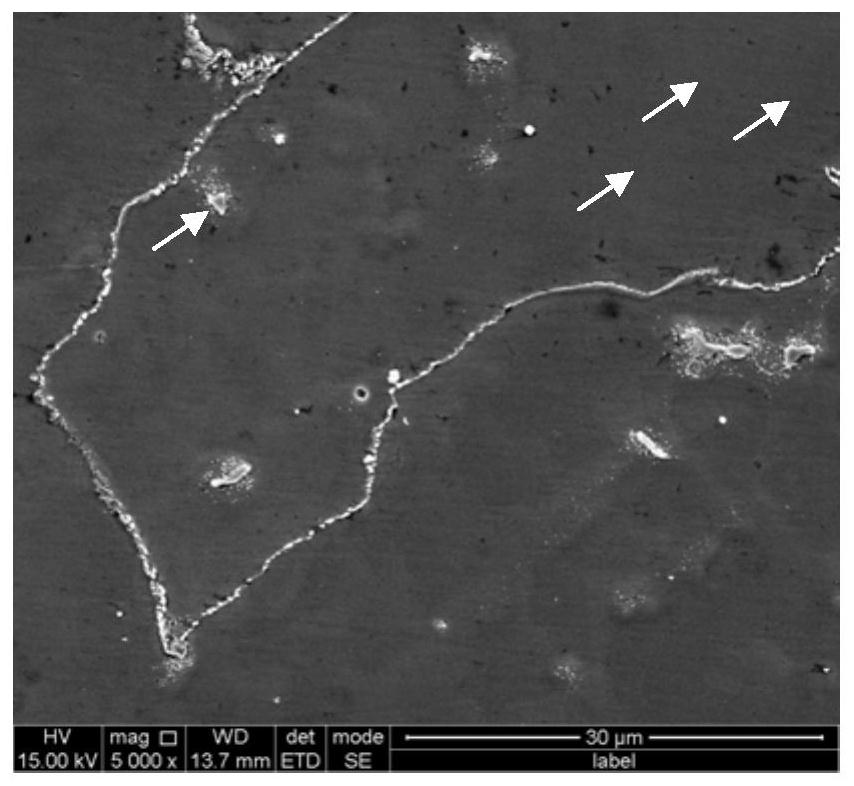

Image

Examples

Embodiment 1

[0024] The chemical composition and weight percentage of welding wire are: C: 0.05%; Si 0.9%; Mn 0.9%; P 0.015%; S0.001%; Cr: 22%; Co: 14%; Mo: 8.8%; W: 1.0%; N 0.0018%; O 0.0015%; the balance is Ni and unavoidable impurity elements. In this embodiment, the welding wire is welded by manual argon arc welding, the specification of C-HRA-2 alloy tube: Φ44.5×10mm, the back of the tube is protected by high-purity argon (≥99.99%), the gas flow rate is 10L / min, and the flow rate of welding torch shielding gas 8L / min; welding wire specification: Φ2.4mm, welding parameters: welding current 130A, arc voltage 13V, preheating temperature 100°C, interpass temperature 100°C; no post-weld heat treatment. The radiographic flaw detection of the welded joint is 100% qualified, and the mechanical properties of the weld metal are: impact energy at room temperature 115J; tensile strength at room temperature 780MPa, yield strength 465MPa.

Embodiment 2

[0026] The chemical composition and weight percentage of welding wire are: C: 0.10%; Si 0.3%; Mn 0.6%; P 0.010%; S0.001%; Cr: 20%; Co: 10%; Mo: 8.1%; W: 0.5%; N 0.0015%; O 0.002%; the balance is Ni and unavoidable impurity elements. In this embodiment, the welding wire is welded by manual argon arc welding, the specification of C-HRA-2 alloy tube: Φ44.5×10mm, the back of the tube is protected by high-purity argon (≥99.99%), the gas flow rate is 10L / min, and the flow rate of welding torch shielding gas 9L / min; welding wire specification: Φ2.4mm, welding parameters: welding current 110A, arc voltage 14V, preheating temperature 100°C, interpass temperature 100°C; no post-weld heat treatment. The radiographic flaw detection of the welded joint is 100% qualified, and the mechanical properties of the weld metal are: impact energy at room temperature 125J; tensile strength at room temperature 775MPa, yield strength 465MPa.

Embodiment 3

[0028] The chemical composition and weight percentage of welding wire are: C: 0.08%; Si 0.5%; Mn 0.6%; P 0.010%; S0.001%; Cr: 21%; Co: 12%; Mo: 8.5%; W: 0.5%; N 0.0019%; O 0.002%; the balance is Ni and unavoidable impurity elements. In this embodiment, the welding wire is welded by narrow gap hot wire TIG welding, the specification of C-HRA-2 alloy tube: outer diameter Φ510mm×wall thickness 85mm, welding wire specification: Φ1.6mm, welding parameters: bottoming parameters: current 120A, voltage 10V, send Wire speed 70cm / min, welding speed 110mm / min, shielding gas is high-purity argon (≥99.99%), flow rate 25L / min; filling parameters: current 150A, voltage 11V, wire feeding speed 90cm / min, welding speed 70mm / min, the shielding gas is high-purity argon (≥99.99%), the flow rate is 27L / min; cover parameters: current 170A, voltage 10V, wire feeding speed 70cm / min, welding speed 50mm / min, shielding gas is high-purity argon (≥99.99%), the flow rate is 30L / min. The interpass tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com