Method for making and installing embedded parts of shaft wellhead of high temperature gas-cooled reactor

A high-temperature gas-cooled reactor and embedded parts technology, which is applied to workpiece clamping devices, manufacturing tools, positioning devices, etc. It is not easy to deform, prevents deformation, and increases the effect of the force area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical scheme of the present invention will be introduced below in conjunction with the accompanying drawings.

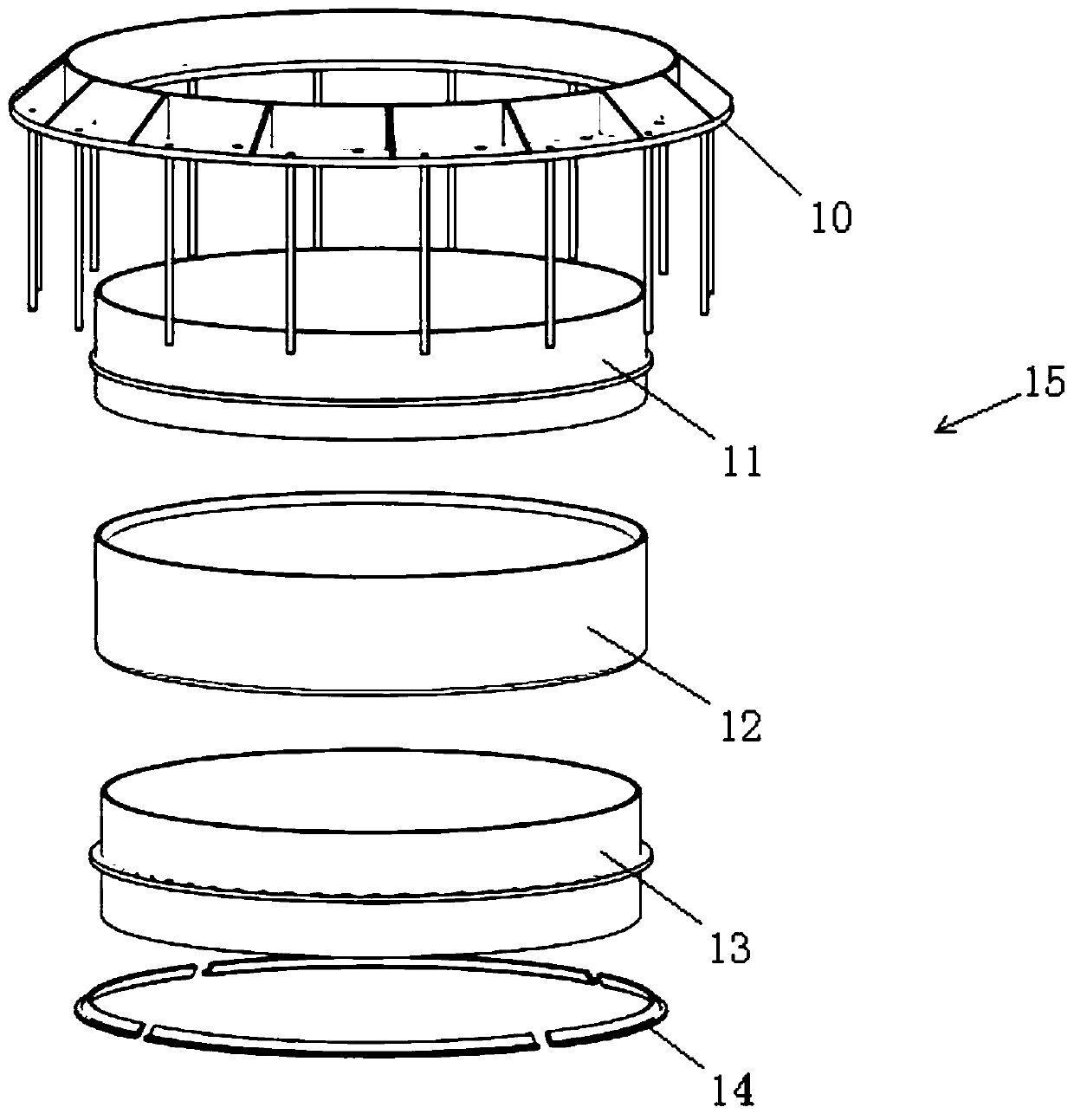

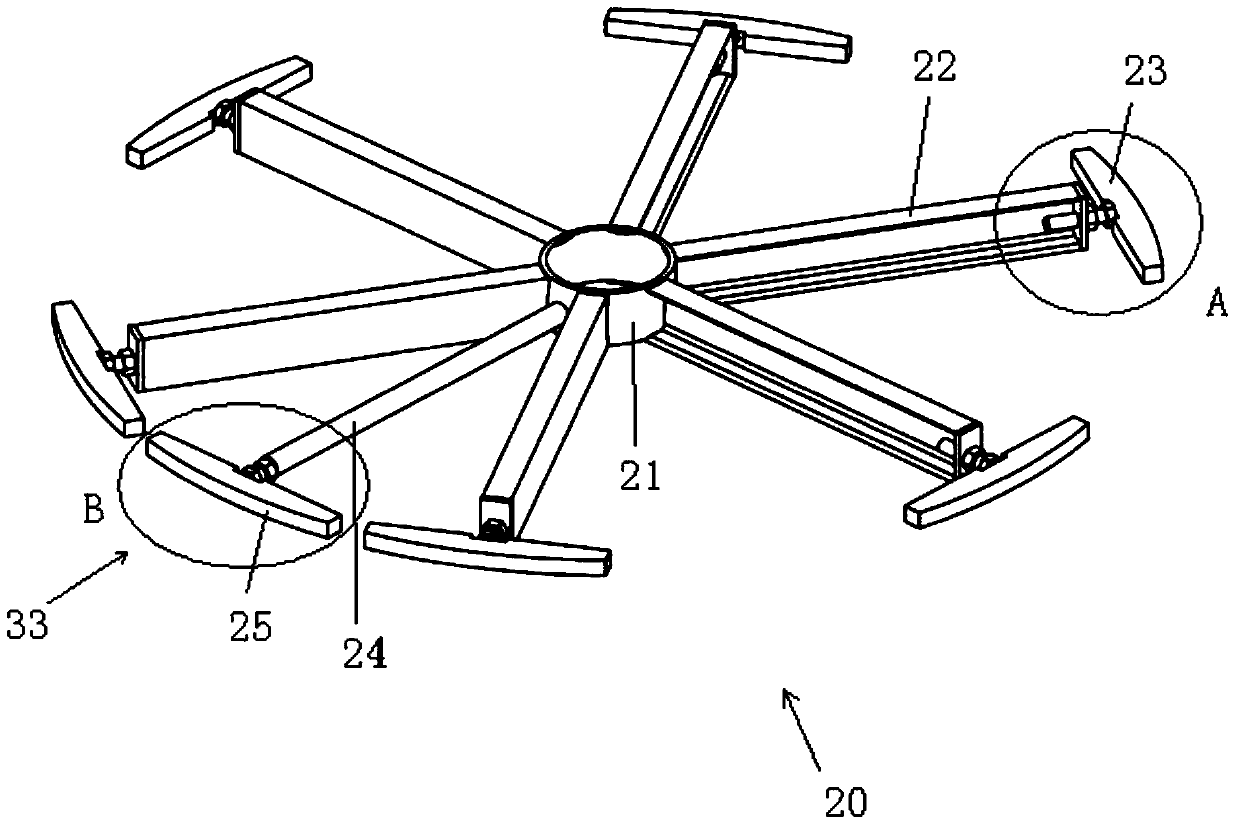

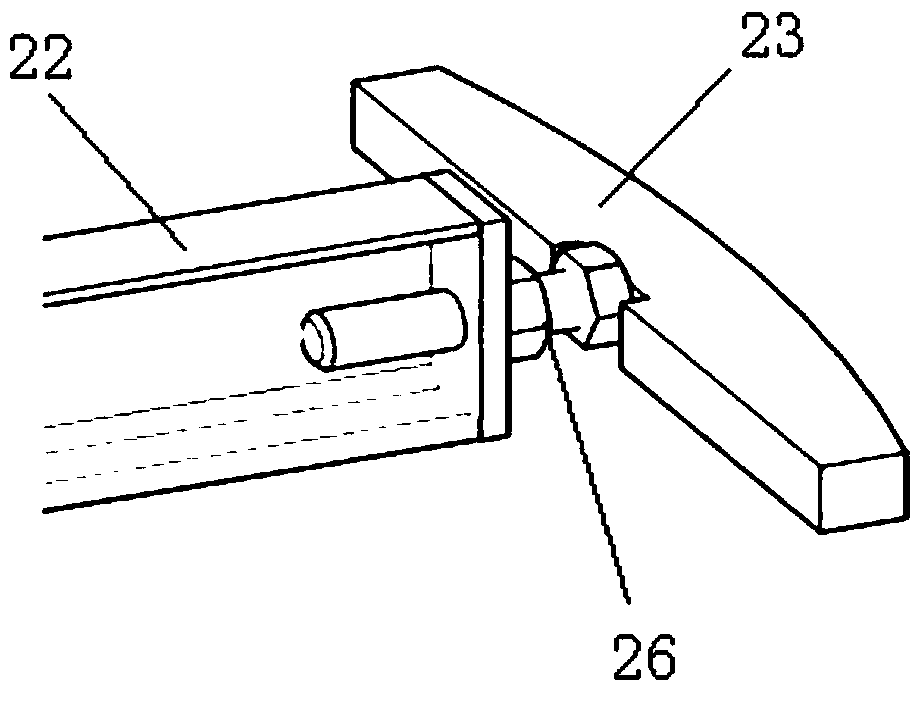

[0044] The auxiliary device for the manufacture and installation of the high temperature gas-cooled reactor shaft wellhead embedded parts of the present invention includes external tooling and at least three internal tooling, such as Figure 2-4 As shown, the internal tooling 20 includes a central tube 21, and on the outer wall of the central tube 21, several support columns 22 are radially distributed. figure 2 Among them, six support columns 22 are distributed radially on the outer wall of the central tube 21, and the number of support columns 22 can be adjusted according to actual needs; the support columns 22 are arranged radially along the central tube 21, that is, the support columns 22 are arranged along the The radial extension of the support columns 22 is evenly distributed on the outer wall of the central tube 21 . Such as image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com