A pressurized ultrasonic cavitation three-phase abrasive flow swirl polishing processing device

A cavitation three-phase, processing device technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of low processing efficiency, slow flow rate, low processing flow field pressure, etc., achieve reasonable structure design, improve polishing efficiency, and improve speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

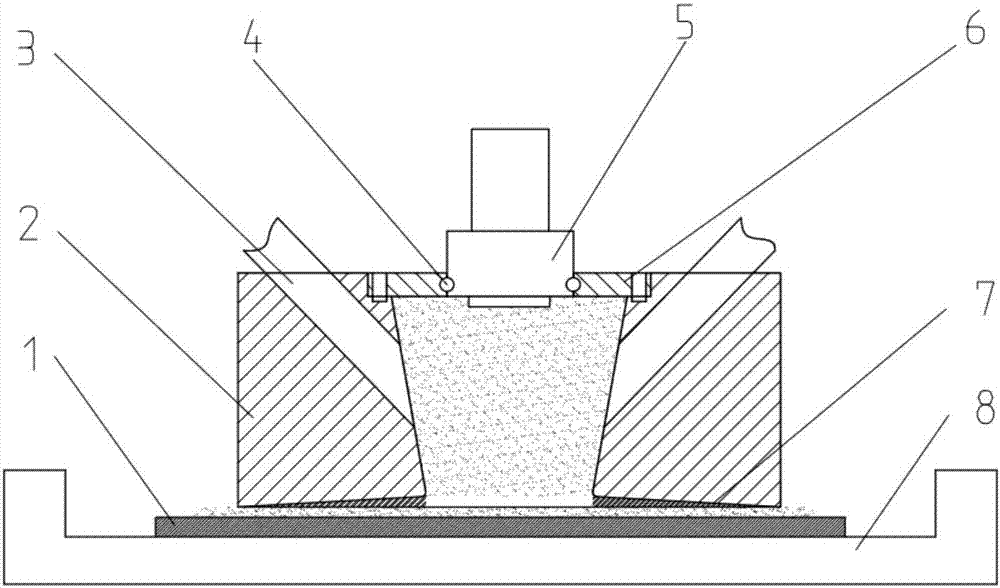

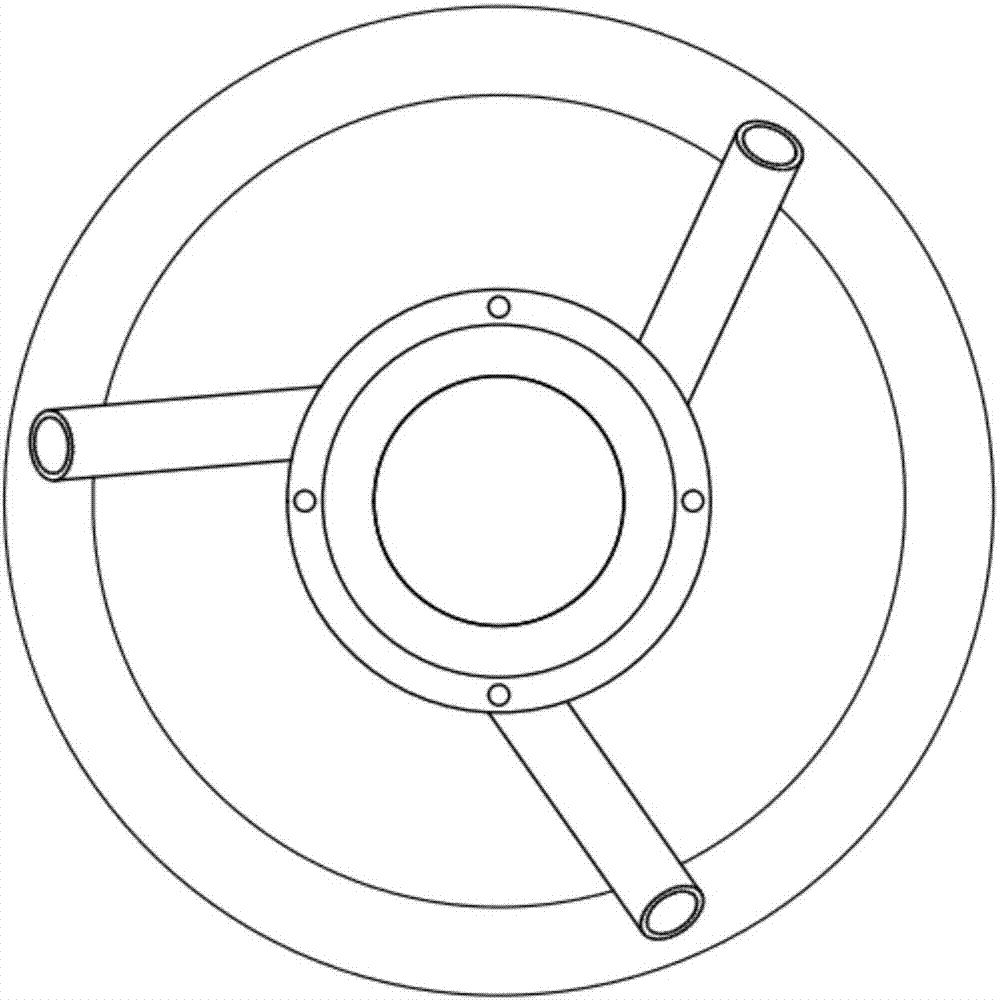

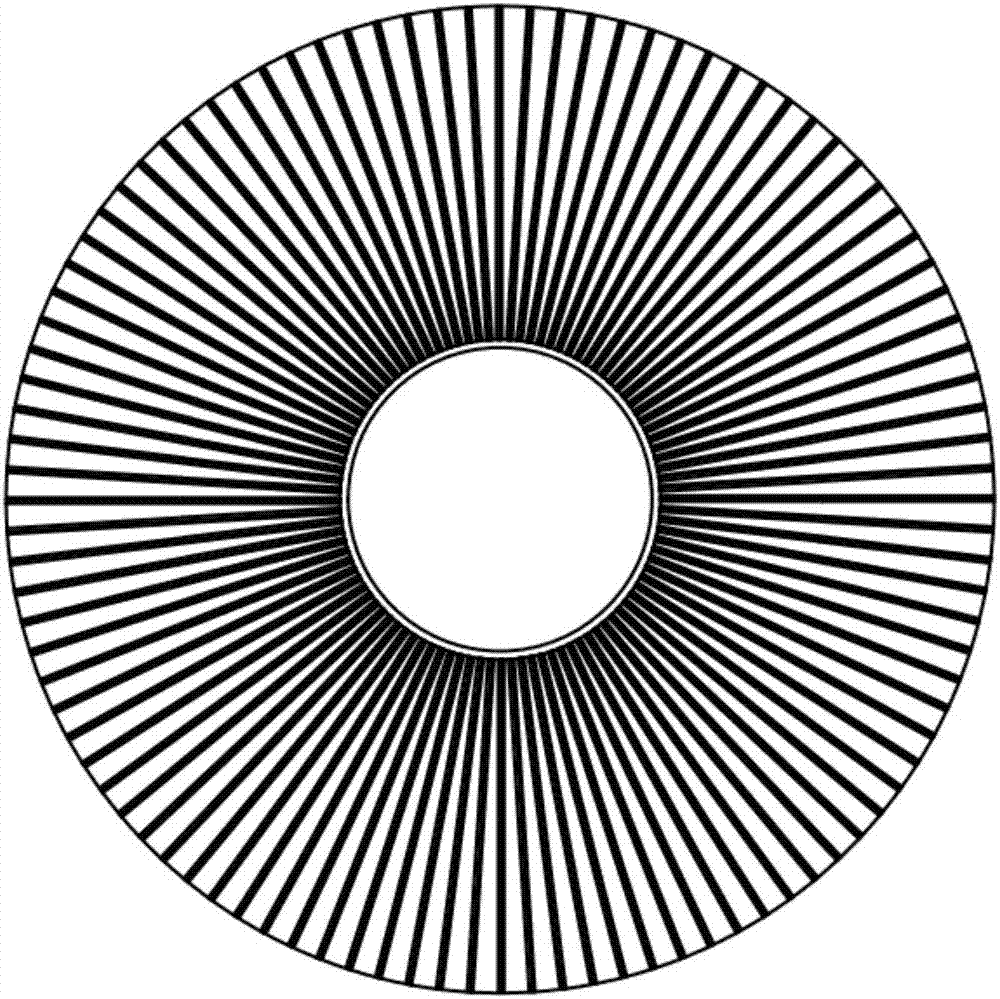

[0021] Such as Figure 1~3 As shown, a pressurized ultrasonic cavitation three-phase abrasive flow swirl polishing processing device includes a disc-shaped swirl polishing tool 2, a workpiece installation platform 8 and an ultrasonic bubble generator 5, and the processed workpiece 1 is installed on the workpiece installation On the platform 8, the disc-shaped swirl polishing tool 2 is fixedly installed directly above the workpiece 1, and the disc-shaped swirl polishing tool 2 forms a micro-distance slit with the surface of the workpiece; the disc-shaped swirl The bottom of the flow polishing tool 2 is provided with a knurling 7 with a certain inclination angle, the inside of the disc-shaped swirl polishing tool 2 is provided with an inverted conical inner cavity, and the top of the disc-shaped swirl polishing tool 2 is provided with a The solid-liquid two-phase abrasive po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com