Post-processing shot blasting device for 3D printed part and working method of post-processing shot blasting device

A 3D printing and shot blasting device technology, which is applied in the direction of abrasive feeding device, manufacturing tools, additive processing, etc., can solve the problems of high time cost of post-processing technology, high risk of operation, low strength of parts, etc., and achieve brightness The coefficient is kept uniform, the risk is reduced, and the effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

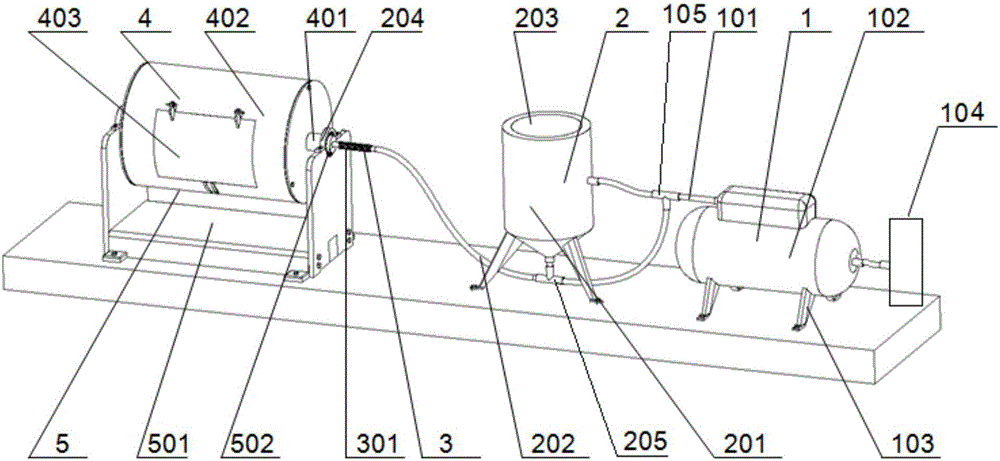

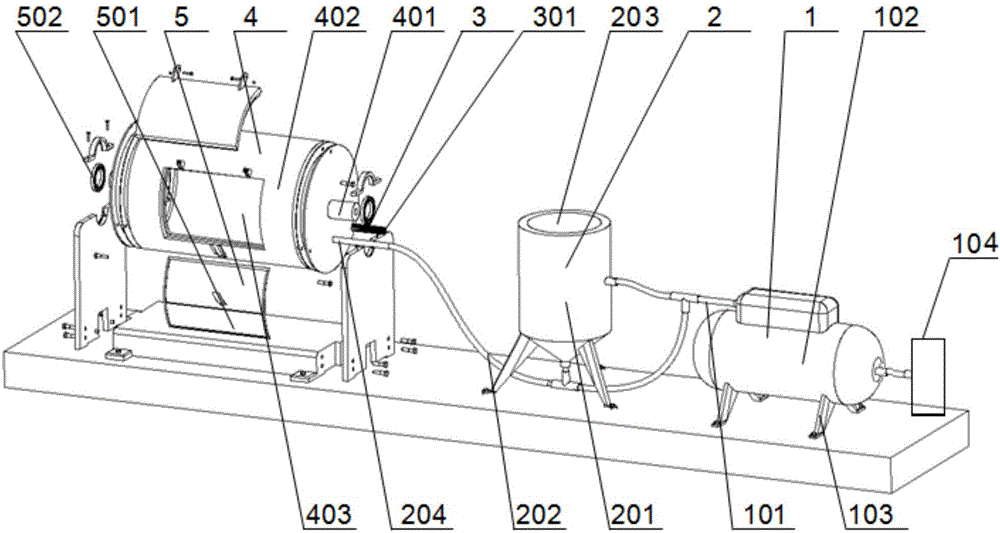

[0036] As shown in the figure, a post-processing shot blasting device for 3D printed parts is characterized by: including an air pump device 1, a shot peening working device 2, a heat treatment device 3, a parts post-processing device 4 and a bracket support device 5,

[0037] The air pump device 1 includes an air guide pipe 101, a gas storage bottle 102, a base 103, an air pump 104 and a tee I 105; 204, three-way II 205 and cone valve; the heat treatment device 3 includes a heating pipe 301 and an electric heating element; the parts post-processing device 4 includes a hollow crankshaft 401, a plexiglass cylinder 402 and a parts inlet 403; the bracket The support device 5 includes a support bottom support 501 and a bearing 502;

[0038] The air pump 104 is connected to the gas storage bottle 102 through the air guide tube 101; the gas storage bottle 102 is connected to the base 103, the gas storage bottle 102 is supported and fixed by the base 103, and the gas storage bottle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com