Manufacturing method of anisotropic optical film

A technology of anisotropy and manufacturing method, applied in the field of manufacturing anisotropic optical films, can solve the problems of easy dazzling, brightness change, easy to produce light interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

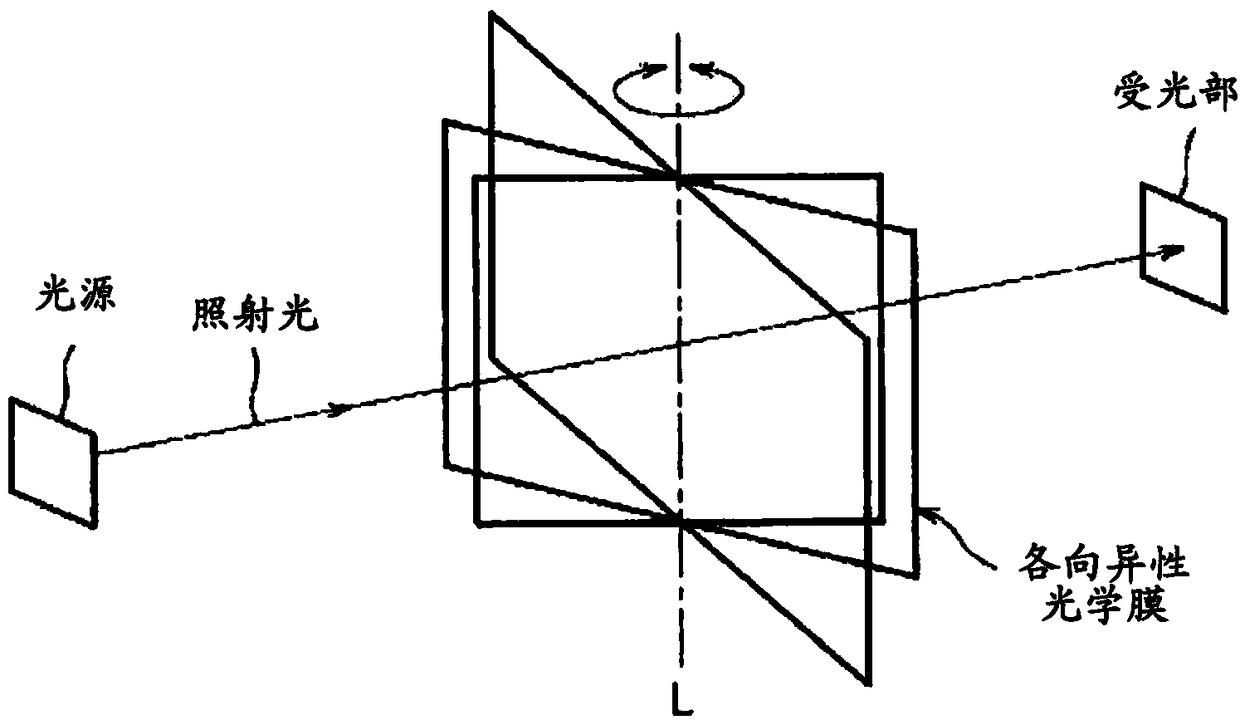

[0135] An anisotropic optical film of the present invention and an anisotropic optical film of a comparative example were produced by the following methods. In addition, in the following content, an anisotropic optical film is a film which consists of only one anisotropic diffusion layer.

[0136]

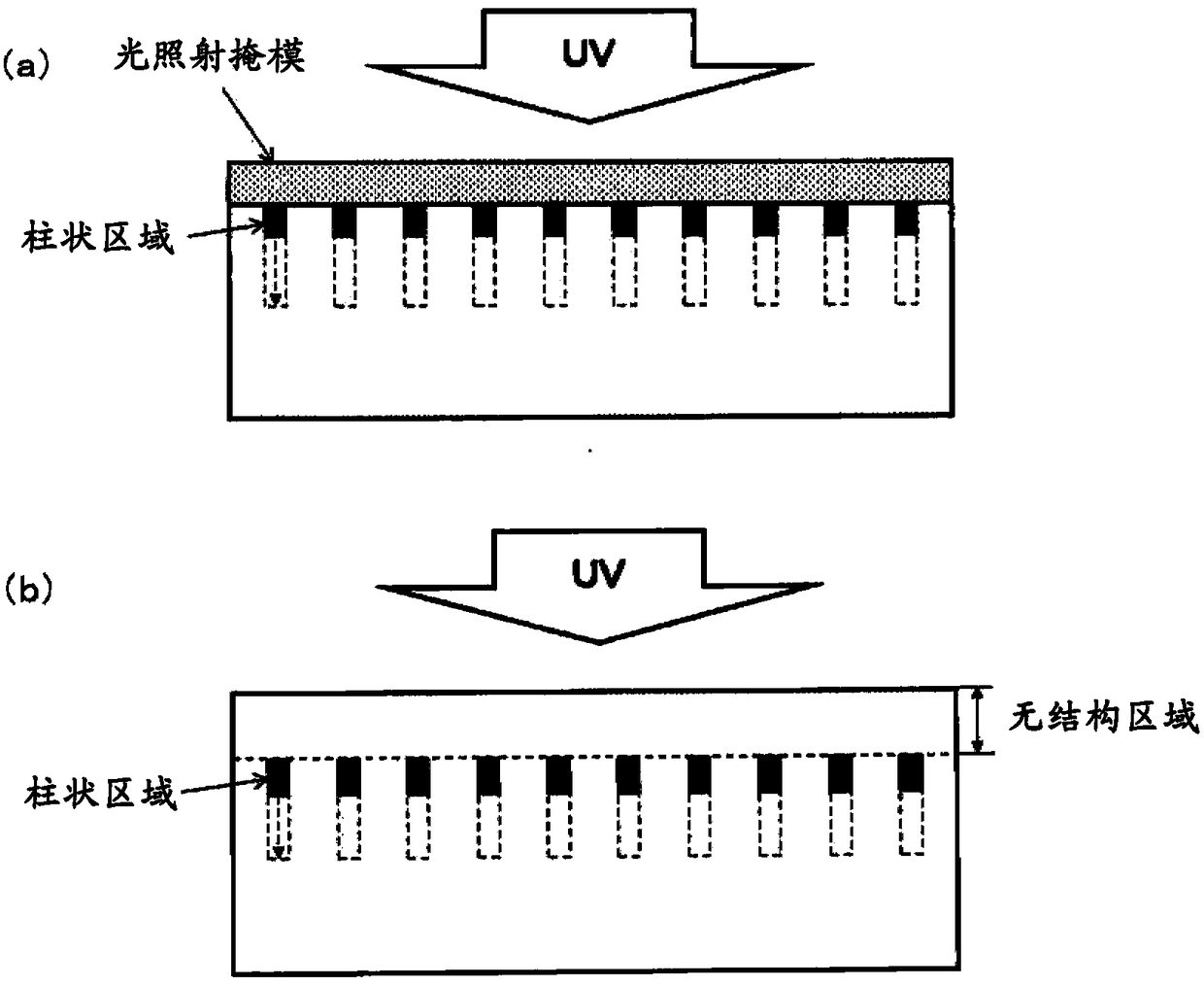

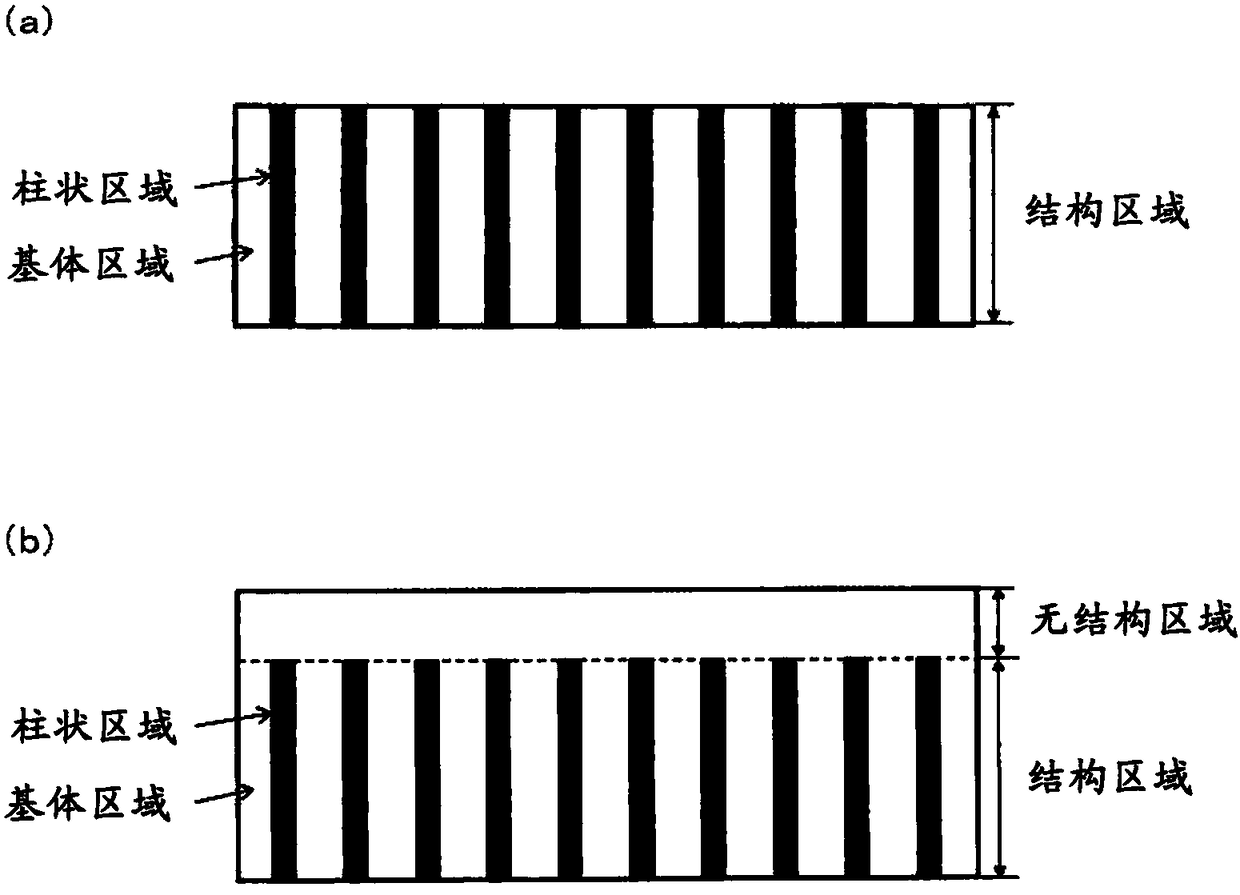

[0137] A PET film with a thickness of 100 μm and a size of 76×26 mm (manufactured by Toyobo Co., Ltd., trade name: A4100, haze=0.5%) was used as the base film, and a photocurable film was applied to the entire periphery of the edge portion using a dispenser. The resin composition forms partition walls. The formed partition walls are shown in Table 1, which differ according to different examples. The height of this partition wall corresponds substantially to the thickness of the obtained anisotropic optical film. The following photocurable resin composition was filled in this partition, and it covered with a UV irradiation mask (photoirradiation mask). However, when the UV irra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com