Surface hydrophobic anti-icing method

An anti-icing and hydrophobic technology, which is applied in the fields of crafts, decorative arts, and gaseous chemical plating for producing decorative surface effects, can solve problems such as high cost, poor practicability, and complex surface, and achieve low cost and simplified The effect of simple formation process and processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

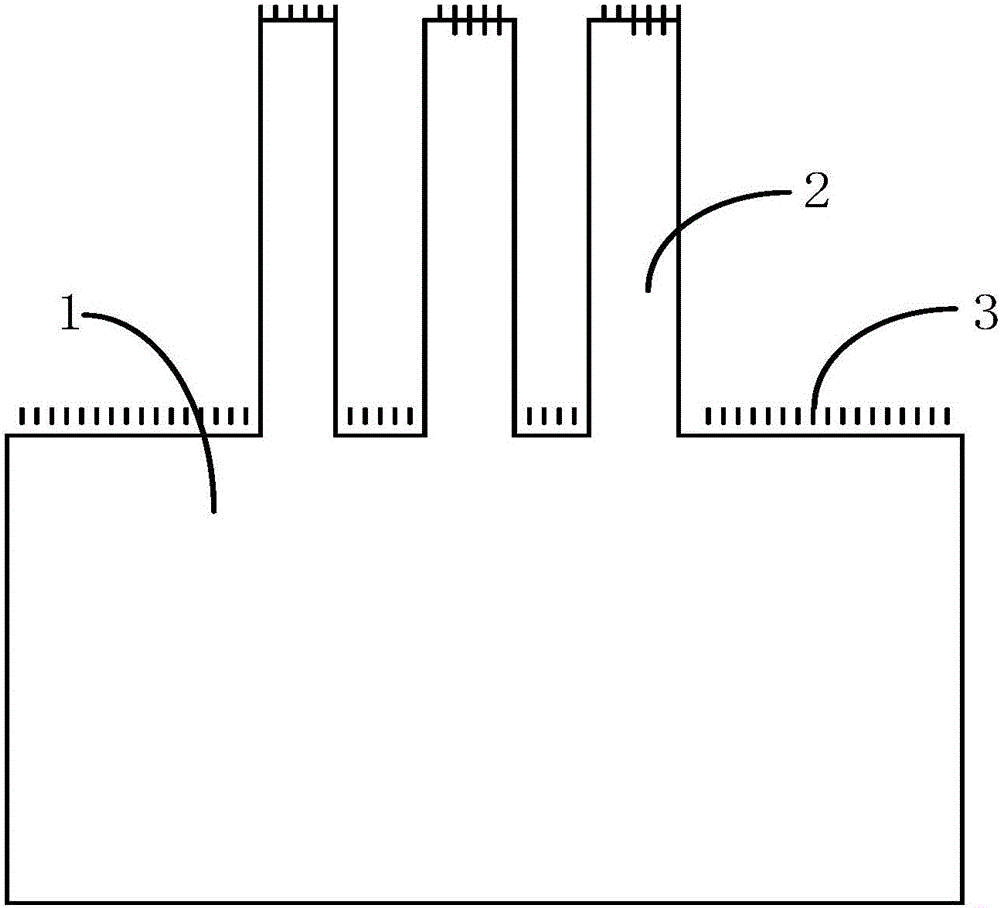

[0044] For deep air pre-cooled engines, anti-icing is the key technology in the design of pre-coolers. According to research, using hydrophobic surface treatment to change the surface characteristics of pre-cooling devices can prevent or delay surface icing and frosting. characteristics, thereby solving the freezing problem of the precooler. Considering the anti-icing characteristics of the hydrophobic surface, the anti-icing problem of the pre-cooling device can be solved by using the hydrophobic surface treatment. characteristics or mechanism, so as to achieve the anti-icing effect. This method has the characteristics of no energy consumption, no pollution, and environmental friendliness, so it has become a research hotspot in the field of anti-icing and anti-frost. However, although the hydrophobic surface can reduce the ice adhesion strength and delay the freezing time of droplets, the solid surface with good hydrophobic performance may not have good anti-icing and anti-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com