A kind of polyurethane foam concrete and preparation method thereof

A technology of polyurethane foam and polyurethane, which is applied in ceramic products, other household appliances, applications, etc., can solve the problems of low strength, large capacity, and high thermal conductivity of foam insulation materials, and achieve improved insulation performance and durability, and high closed cell rate , good waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

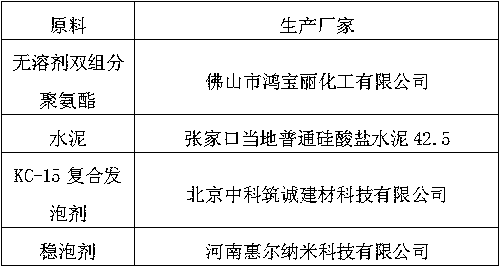

Image

Examples

Embodiment 1

[0043] Embodiment 1 of the present invention provides the preparation method of polyurethane foam concrete comprising the following steps:

[0044] Step 1, preparing polyurethane aggregate; adding water, polyurethane black material and polyurethane white material in sequence to the cement, stirring evenly while adding, and standing to obtain polyurethane aggregate; the specific preparation method is as follows,

[0045] Step a, according to the ratio of water-cement ratio is 0.35, adding water to the cement, stirring evenly while adding;

[0046] Step b, add polyurethane black material accounting for 10% of the cement mass to the solution prepared in step a, stir quickly and evenly, and stir for 20s to 30s;

[0047] Step c, add polyurethane white material accounting for 10% of the cement mass to the solution prepared in step b, stir quickly and evenly, and stir for 20s to 30s;

[0048] Step d, standing still for 5 minutes, until the foam no longer changes, that is, the polyur...

Embodiment 2

[0067] Embodiment 2 of the present invention provides the preparation method of polyurethane foam concrete comprising the following steps:

[0068] Step 1, preparing polyurethane aggregate; adding water, polyurethane black material and polyurethane white material in sequence to the cement, and stirring evenly while adding, and standing to obtain polyurethane aggregate; the specific preparation method is as follows,

[0069] In step a, according to the ratio of water-cement ratio of 0.4, water is added to the cement, stirring while adding, and stirring evenly;

[0070] Step b, add polyurethane black material accounting for 15% of the cement mass to the solution prepared in step a, stir quickly and evenly, and stir for 20s to 30s;

[0071] Step c, add polyurethane white material accounting for 15% of the cement mass to the solution prepared in step b, stir quickly and evenly, and stir for 20s to 30s;

[0072] Step d, standing still for 5 minutes, until the foam no longer change...

Embodiment 3

[0091] Embodiment 3 of the present invention provides the preparation method of polyurethane foam concrete comprising the following steps:

[0092] Step 1, preparing polyurethane aggregate; adding water, polyurethane black material and polyurethane white material in sequence to the cement, and stirring evenly while adding, and standing still to obtain polyurethane aggregate;

[0093] The specific preparation method is as follows,

[0094] Step a, according to the ratio of water-cement ratio of 0.5, add water to the cement, and stir evenly while adding;

[0095] Step b, add polyurethane black material accounting for 20% of the cement mass to the solution prepared in step a, stir quickly and evenly, and stir for 20s to 30s;

[0096] Step c, add polyurethane white material accounting for 20% of the cement mass to the solution prepared in step b, stir quickly and evenly, and stir for 20s to 30s;

[0097] Step d, standing still for 5 minutes, until the foam no longer changes, tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com