Micropore terbium-based metal-organic framework material and preparation method and application thereof

An organic framework and metal-based technology, applied in the field of crystalline materials science, can solve the problems that are rarely reported, and achieve the effect of cheap and easy-to-obtain synthetic raw materials, mild conditions, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

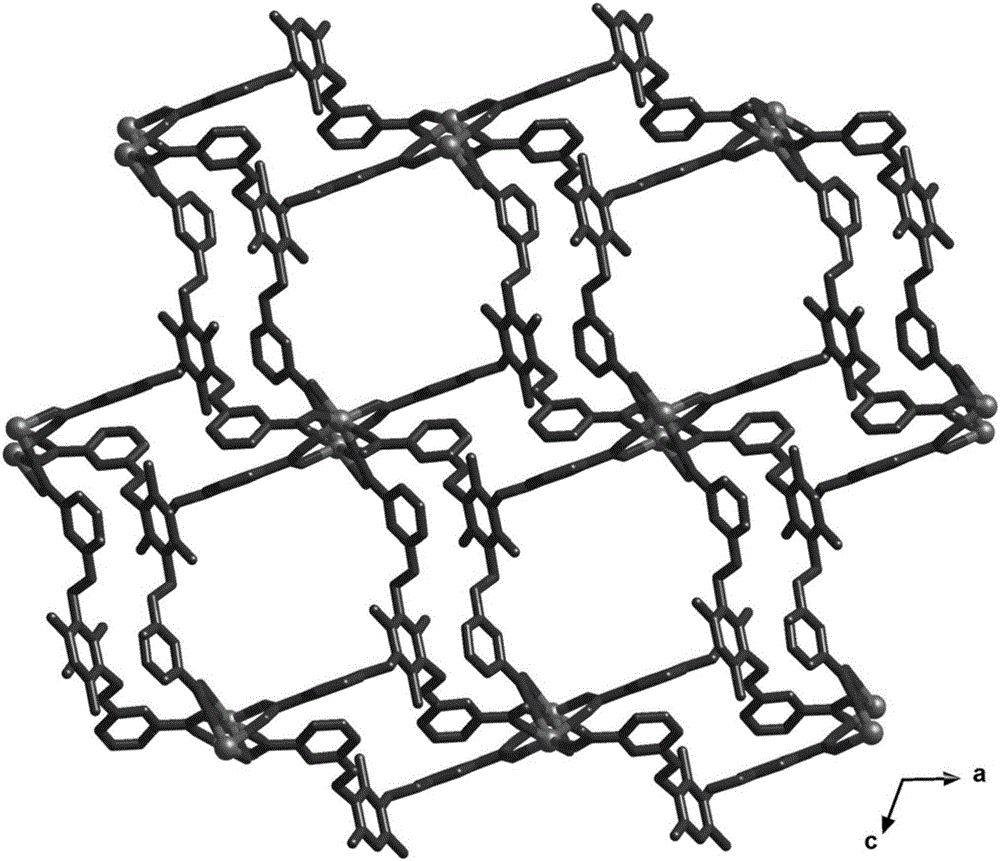

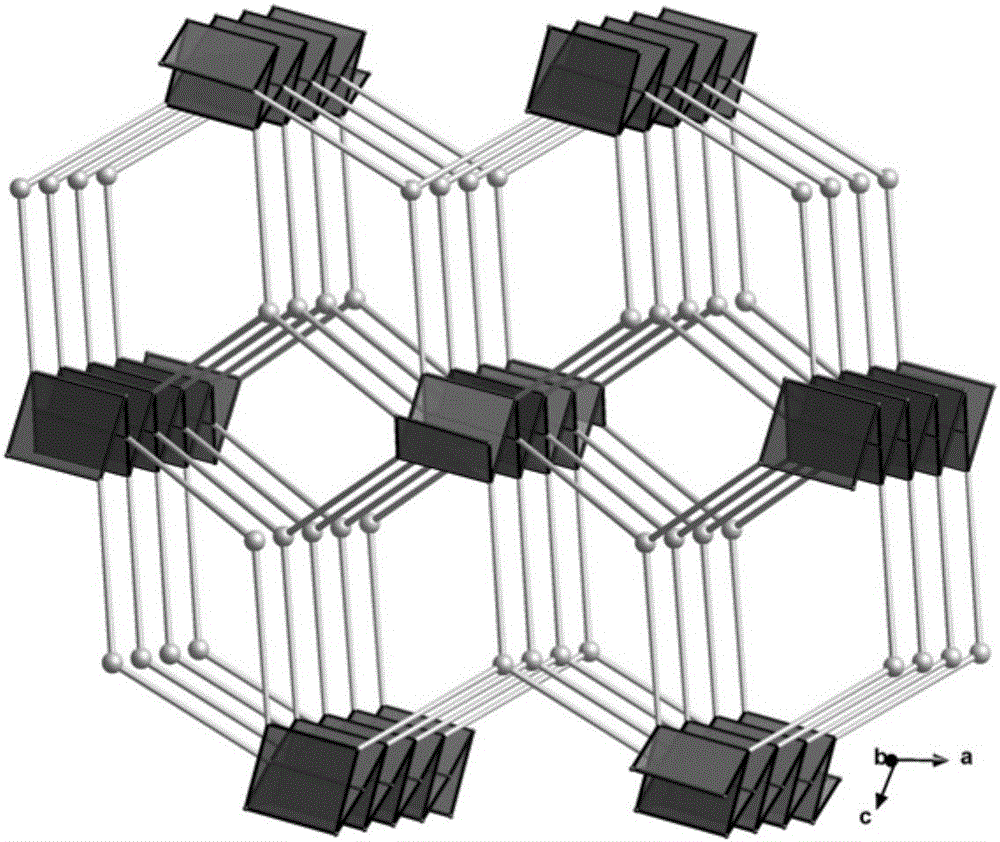

[0029] Example 1: Preparation of microporous terbium-based metal-organic framework materials

[0030] Mix 2,4,6-tris[1-(3-carboxyphenoxy)methyl]-1,3,5-trimethylbenzene (0.03 mmol, 17.1 mg) with terbium nitrate (preferably terbium nitrate hexahydrate , 0.1mmol, 45.4mg) was dissolved in a mixed solvent of DMF (6mL) and NMP (1mL) and sealed in a 25mL hydrothermal reaction kettle. Then the reaction mixture was heated at 10° C. per hour to 140° C., maintained at this temperature for 3 days, and then lowered to room temperature to obtain colorless prismatic crystals with a yield of about 50%. The main infrared absorption peaks are: 3394m, 1656s, 1551s, 1442s, 1408s, 1238m, 1134w, 1010m, 827w, 772m, 685w.

Embodiment 2

[0031] Example 2: Preparation of microporous terbium-based metal-organic framework materials

[0032] 2,4,6-tris[1-(3-carboxyphenoxy)methyl]-1,3,5-trimethylbenzene (0.2mmol, 114.1mg) and terbium nitrate (0.5mmol, 226.5mg) Dissolve in a mixed solvent of DMF (5mL) and NMP (5mL) and seal in a 25mL hydrothermal reactor. Then the reaction mixture was heated at 10°C per hour to 120°C, maintained at this temperature for 3 days, and then lowered to room temperature to obtain colorless prismatic crystals with a yield of about 35%. The main infrared absorption peaks are: 3394m, 1656s, 1551s, 1442s, 1408s, 1238m, 1134w, 1010m, 827w, 772m, 685w.

Embodiment 3

[0033] Example 3: Preparation of microporous terbium-based metal-organic framework materials

[0034] 2,4,6-tris[1-(3-carboxyphenoxy)methyl]-1,3,5-trimethylbenzene (0.02mmol, 11.4mg) and terbium nitrate (0.08mmol, 36.2mg) Dissolve in a mixed solvent of DMF (6mL) and NMP (4mL) and seal in a 25mL hydrothermal reaction kettle. Then the reaction mixture was heated at 10° C. per hour to 120° C., maintained at this temperature for 3 days, and then lowered to room temperature to obtain colorless prismatic crystals with a yield of about 45%. The main infrared absorption peaks are: 3394m, 1656s, 1551s, 1442s, 1408s, 1238m, 1134w, 1010m, 827w, 772m, 685w.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com