A YAB/SIO2 near-infrared micro-nano composite luminescent material synergistic EVA film and its preparation method and application

A luminescent material, micro-nano technology, applied in luminescent materials, chemical instruments and methods, photovoltaic power generation, etc., can solve the problems of near-infrared micro-nano luminescent materials that are difficult to uniformly disperse, unfavorable for battery photoelectric conversion efficiency, and unfavorable for industrialized production, etc. Easy long-term storage, stable fluorescence performance, uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of YAB / SiO provided by the present embodiment 2 The preparation method of the micro-nano near-infrared emitting material, the specific steps are as follows:

[0050] 1) take by weighing following material: the Y of 95.3822g 2 o 3 , 136.5448g Al 2 o 3 , 249.2986g of H 3 BO 3 , 23.2848g of Bi(NO 3 ) 3 ·5H 2 O, 13.2410 g of Yb 2 o 3 , 15.3206g Cr 2 o 3 .

[0051] 2) Mix and stir the above-mentioned raw materials in a high-speed disperser;

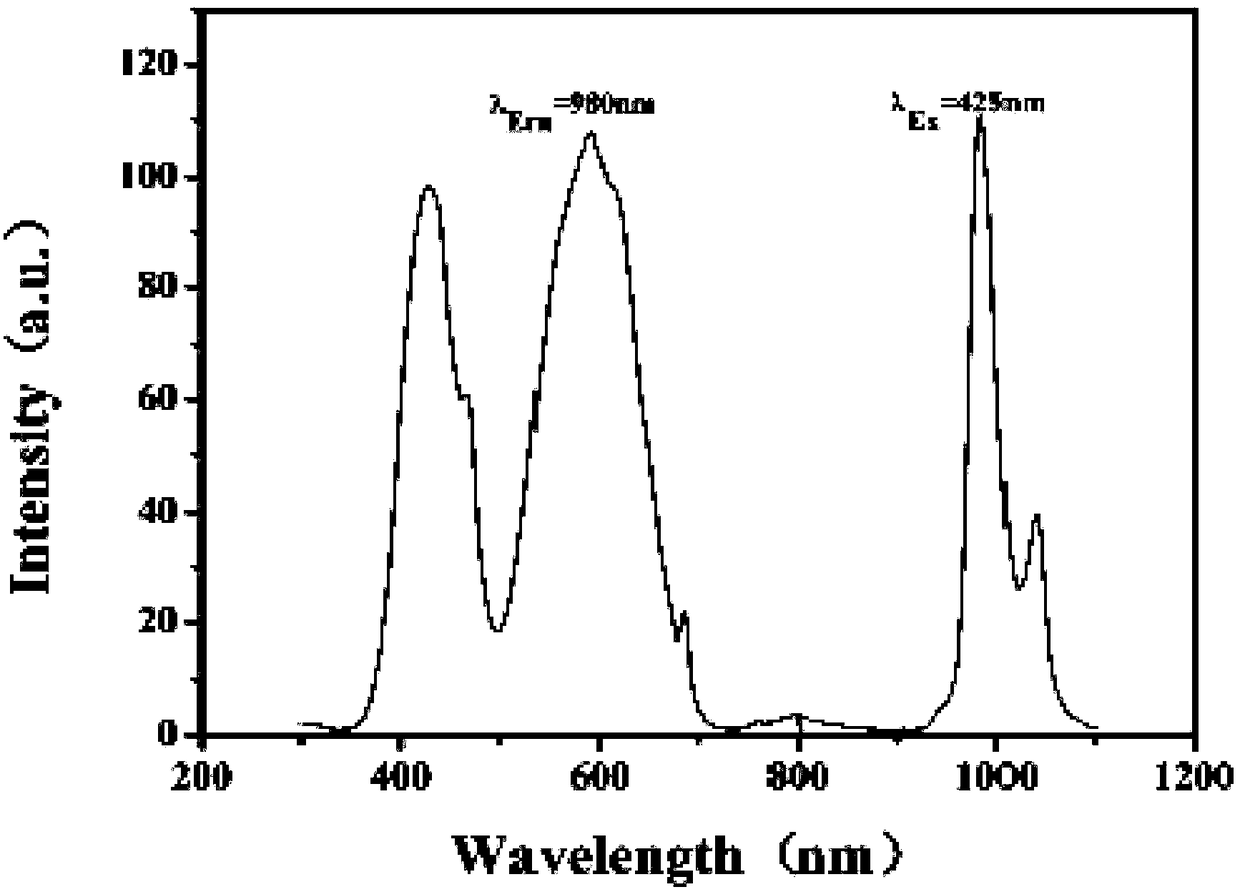

[0052] 3) Sinter the above uniformly mixed powder in a high-temperature furnace at 1200°C for 6 hours to obtain a YAB fluorescent emission material. The excitation and emission spectra are as follows: figure 1 shown;

[0053] 4) Take 200g of the above-mentioned YAB fluorescent emitting material in a ball mill jar, add nano-SiO 2 16g, after adding appropriate amount of agate beads for ball milling and deionized water, ball mill for 12 hours;

[0054] 5) The above ball-milled slurry is dried at 120°C in a blast dr...

Embodiment 2

[0058] A kind of YAB / SiO provided by the present embodiment 2 The preparation method of the micro-nano near-infrared emitting material is basically the same as that of Example 1, except that:

[0059] Step 5) change the above-mentioned 200g YAB fluorescent emitting material after ball milling and 16g SiO 2 The airgel was stirred and mixed in the ethanol solution for 1 hour.

Embodiment 3

[0061] A kind of YAB / SiO provided by the present embodiment 2 The preparation method of the micro-nano near-infrared emitting material is basically the same as that of Example 1, the difference is:

[0062] SiO in step 5) 2 The amount of airgel added is changed to 12g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com