Composition for making hard coating layer

A hard coating and composition technology, applied in coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of being unsuitable for protective window covers, difficult to achieve high hardness, and insufficient flexibility, and achieve durable Improved scratch resistance and adhesion, improved hardness and flexibility, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0117] Production Example 1. Production of Radical Polymerizable Composition (A-1)

[0118] 55 parts by weight of 6-functional acrylate DPEA-12 (manufactured by Nippon Kayaku Co., Ltd.), 40 parts by weight of 2-functional acrylate M-280 (manufactured by Miwon Specialty Chemical Company) and 5 parts by weight of photoinitiator Irgacure-184 (manufactured by BASF Company) parts were mixed to prepare a free radically polymerizable composition.

manufacture example 2

[0119] Production Example 2. Production of Radical Polymerizable Compound (A-2)

[0120] 30 parts by weight of 6-functional acrylate DPEA-12 (manufactured by Nippon Kayaku Co., Ltd.), 25 parts by weight of 10-functional urethane acrylate oligomer UV-1700 (manufactured by SK-cytec), Nanocryl C165 (manufactured by Evonik Ltd. .manufactured) 40 parts by weight and 5 parts by weight of a photoinitiator Irgacure-184 (manufactured by BASF Corporation) were mixed to prepare a radically polymerizable composition.

manufacture example 3

[0121] Production example 3. Production of cationically polymerizable composition (B)

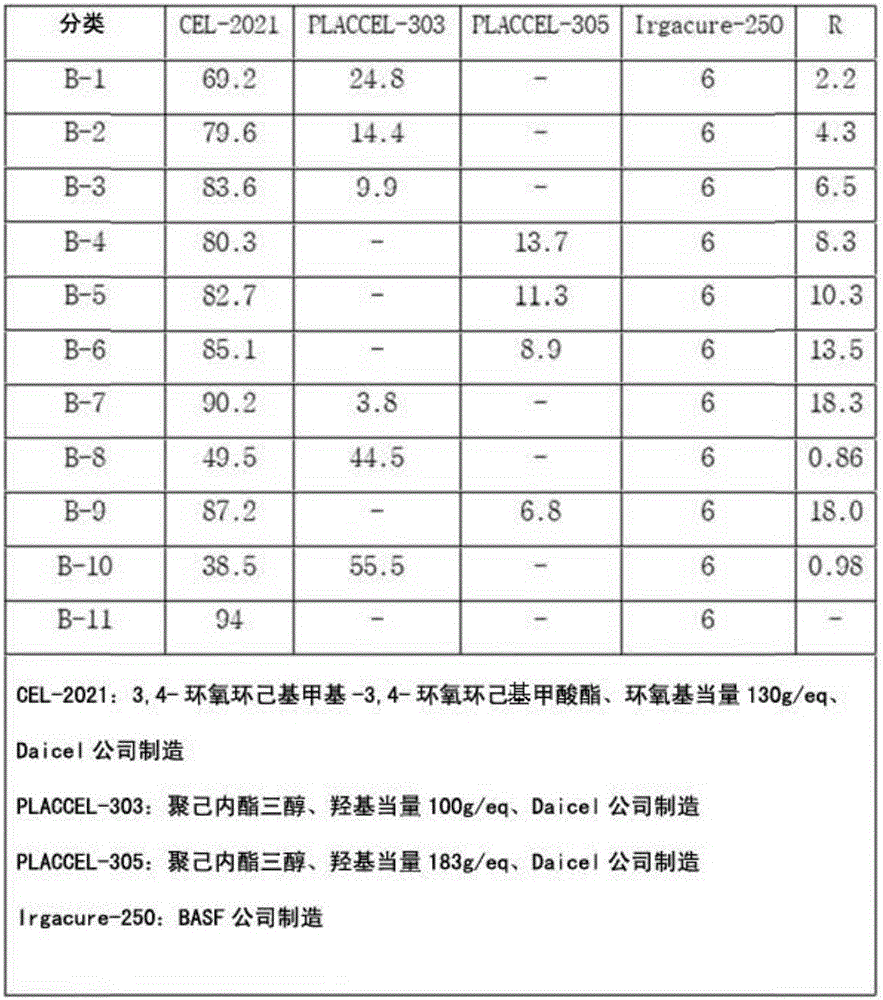

[0122]A cationically polymerizable composition was prepared according to the composition and parts by weight shown in Table 1 below.

[0123] [Table 1]

[0124]

[0125] Examples and Comparative Examples

[0126] The composition for hard-coat layer formation was prepared according to the composition and weight part shown in following Table 2.

[0127] [Table 2]

[0128]

[0129] Manufacture and evaluation of hard coat film

[0130] The compositions of Examples and Comparative Examples were coated on one side of a polyimide film (manufactured by Mitsubishi Gas Chemical Co., Ltd., 100 μm, L-3430) so that the thickness after drying became 20 μm, and the composition was dried in an oven at 80° C. Let dry for 5 minutes. Then, it hardened|cured with the light quantity of 1000mJ by the metal halide lamp (FE), and performed the post-processing for 30 minutes in the oven of 80 degreeC, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com