A kind of mixed acid system containing ionic liquid and nitric acid catalyzes the method for synthesizing alkylated oil

An ionic liquid and alkylated oil technology, which is applied in the production of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc., can solve the problems of high price of ionic liquids and low economical efficiency of new processes, and can accelerate the pace of gasoline upgrading, The effect of improving competitiveness and productivity, increasing octane rating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

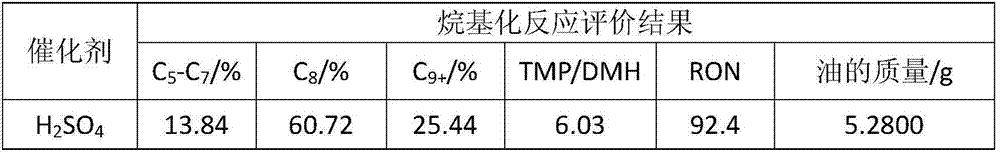

Embodiment 1

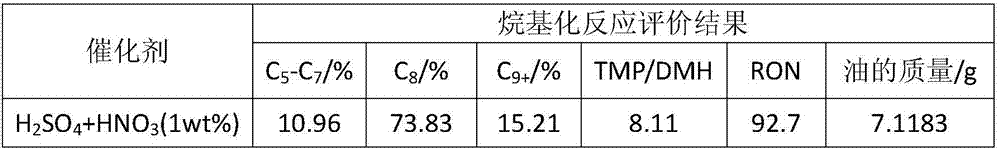

[0026] Concentrated H 2 SO 4 and HNO 3 The mixed acid acts as a catalyst to catalyze the C4 alkylation reaction. HNO 3The addition amount of is 1wt%. Add an appropriate amount of catalyst to the reaction kettle cleaned with ethanol and dried, tighten the lid of the kettle, fill the reaction kettle with nitrogen to ensure a pressure of 0.4MPa, start the stirrer, and set the rotation speed to 1000r / min. Turn on the feed gas sampling pump and set the sampling rate to 500ml / h. Set the temperature of the circulating alcohol bath to 1°C, and when the thermometer in the reaction kettle reaches the set temperature, add 50ml of raw material gas, and continue the reaction for 10 minutes after the addition is complete.

[0027] After the reaction was over, the stirring was stopped and left to stand for 15 min. After the liquid product is left to stand for stratification, take the upper layer liquid, wash it with 0.05M NaOH solution three times, then wash it with water three times, ...

Embodiment 2

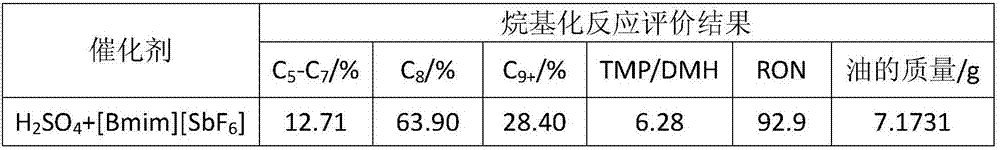

[0032] Concentrated H 2 SO 4 and ionic liquids [Bmim][SbF 6 ] as a catalyst to catalyze the C4 alkylation reaction. The added amount of ionic liquid is 0.1wt%. Reaction steps are as embodiment 1, and evaluation result is as shown in table 3:

[0033] table 3

[0034]

Embodiment 3

[0036] Use H 2 SO 4 and ionic liquids [Bmim][HSO 4 ] as a catalyst to catalyze the C4 alkylation reaction. The addition amount of ionic liquid is 0.6wt%. Reaction steps are as embodiment 1, and evaluation result is as shown in table 4:

[0037] Table 4

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com