Method for producing Luzhou-flavor liquor in liquid state

A Luzhou-flavor liquor, liquid technology, applied in the field of food processing, can solve the problems of the mechanization difficulty of Luzhou-flavor liquor, unfavorable transfer and transportation of materials, easily interrupted material conveying chain, etc. The effect of pure, stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

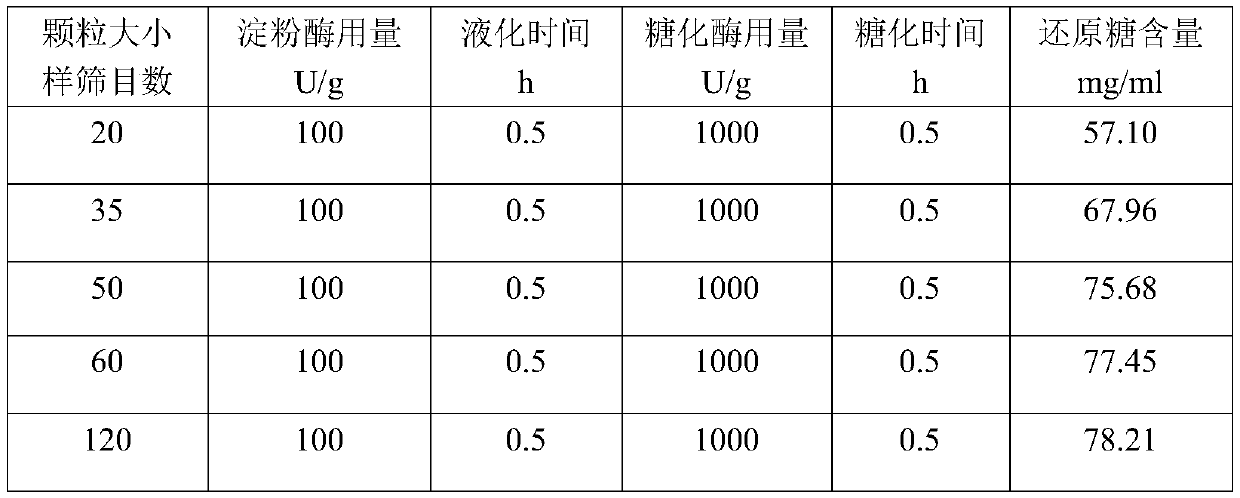

[0051] Example 1 Effect of sorghum crushing degree on liquefaction

[0052] Solid-to-liquid ratio 1:5, amylase action temperature 90°C, pH 5.5-6.0; glucoamylase action temperature 60°C, pH 4.5-5.0

[0053] Table 1 Effect of sorghum crushing degree on liquefaction

[0054]

[0055] From the data in Table 1, it can be seen that the smaller the sorghum crushing degree, the better the liquefaction effect; but the effect on the liquefaction effect becomes smaller and smaller when the sorghum crushing degree is 50 to 60 mesh. For the convenience of practical operation, we choose the sorghum grinding degree to be 50 to 60 mesh.

Embodiment 2

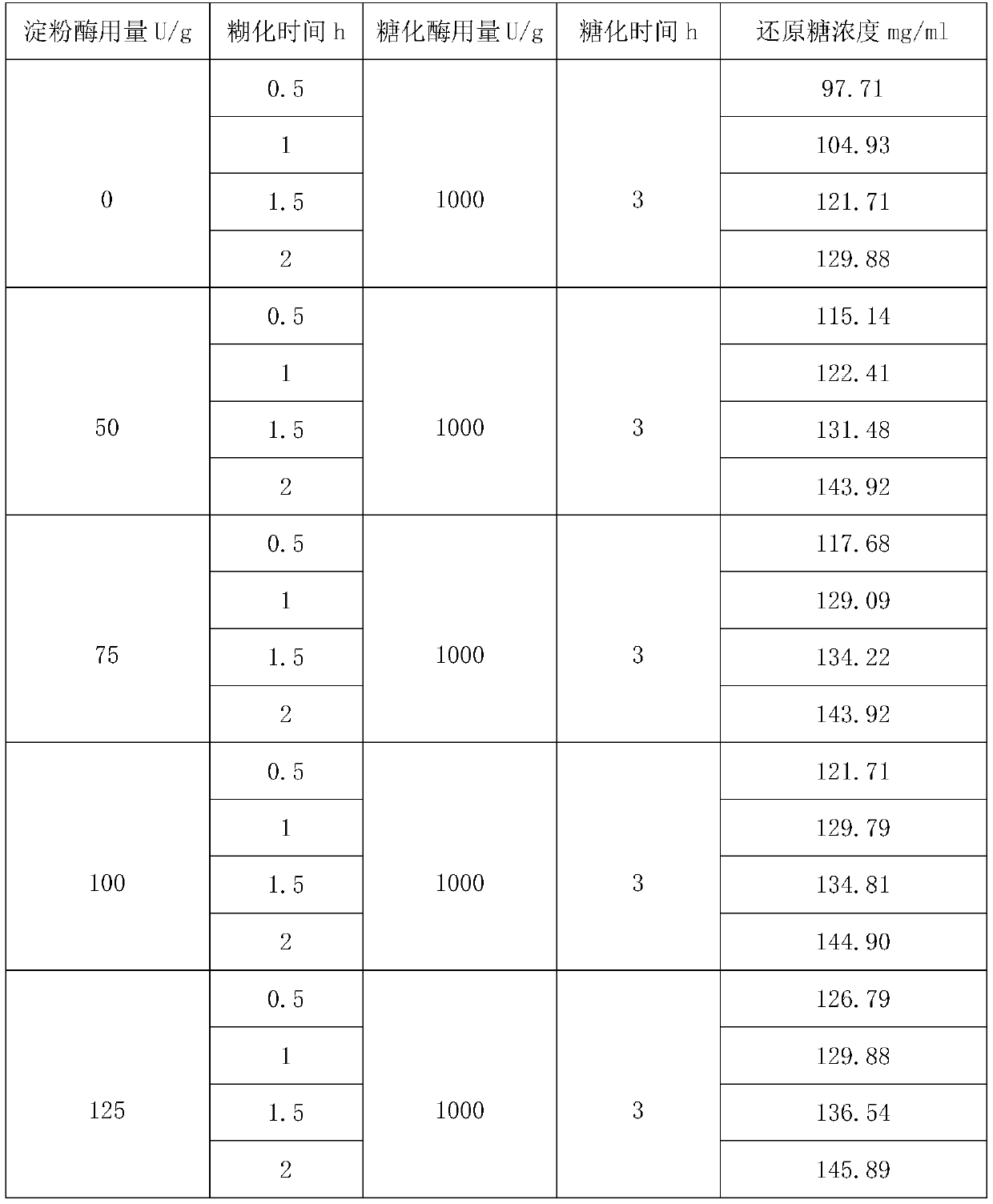

[0056] The consumption of embodiment 2 amylases and the selection of action time

[0057] Solid-to-liquid ratio 1:5, amylase action temperature 90°C, pH 5.5-6.0; glucoamylase action temperature 60°C, pH 4.5-5.0

[0058] The consumption of table 2 amylase and the selection of action time

[0059]

[0060] It can be seen from Table 2 that when the amount of amylase increases from 0 to 75U / g, the content of reducing sugar increases rapidly, and the growth rate of reducing sugar content gradually slows down after 75U / g. Because amylase can still play a certain role in the subsequent long-term saccharification and fermentation process, considering the comprehensive consideration of economic energy consumption, we choose the amylase dosage to be 50U / g, and the action time to be 1h (90°C, pH5.5- 6.0).

Embodiment 3

[0061] Embodiment 3 The mode of saccharification and fermentation and the selection of parameters

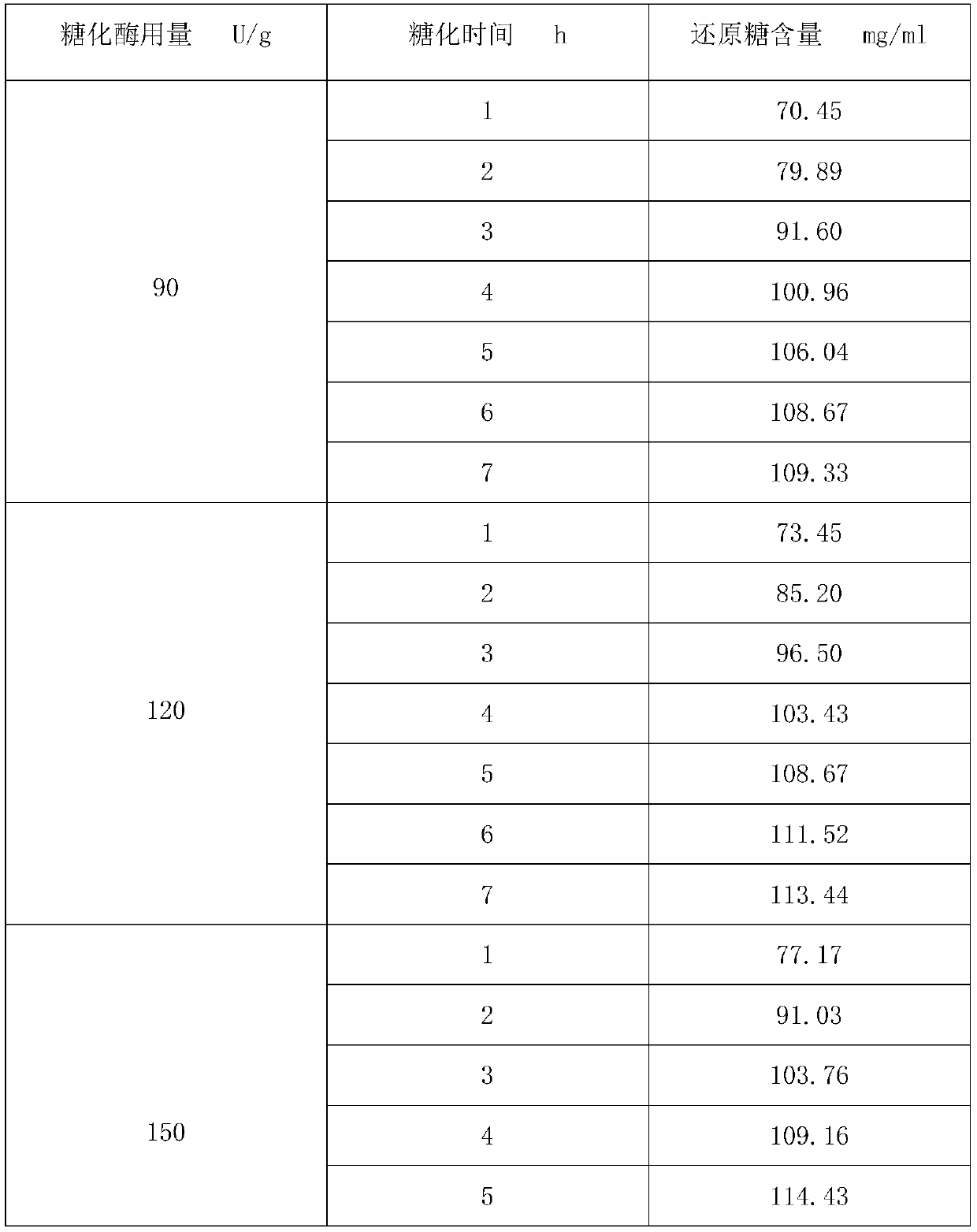

[0062] 1) The dosage of glucoamylase and the selection of saccharification time in the method of saccharification first and then fermentation

[0063] The solid-to-liquid ratio is 1:5, with dilute H 2 SO 4 Adjust the pH to 5.5-6.0, add 50 U / g of amylase, liquefy at 90°C for 1 hour, and stir at intervals; use dilute H 2 SO 4 Adjust the pH to 4.5-5.0; the action temperature of glucoamylase is 60°C.

[0064] Table 3 The dosage of glucoamylase and the selection of saccharification time in the method of saccharification first and then fermentation

[0065]

[0066]

[0067] It can be seen from Table 3 that at the same concentration of glucoamylase, the content of reducing sugar increases with the prolongation of saccharification time, but the increase is very small after 6 hours; at the same saccharification time, the content of reducing sugar increases with the increase of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com