Processing method for obtaining high-proportion special grain boundary from tin bronze

A special grain boundary and processing method technology, applied in the field of grain boundary engineering, can solve a wide range of problems such as immaturity, inability to determine the crystal geometric relationship of the grain interface, and difficulty in defining the degree of freedom, so as to achieve simple equipment and stable texture , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0010] The invention provides a processing method for obtaining a high proportion of special grain boundaries in tin bronze, which is characterized in that it comprises the following steps:

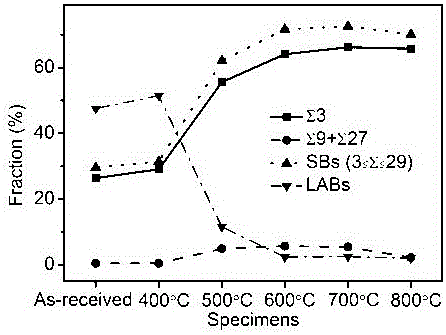

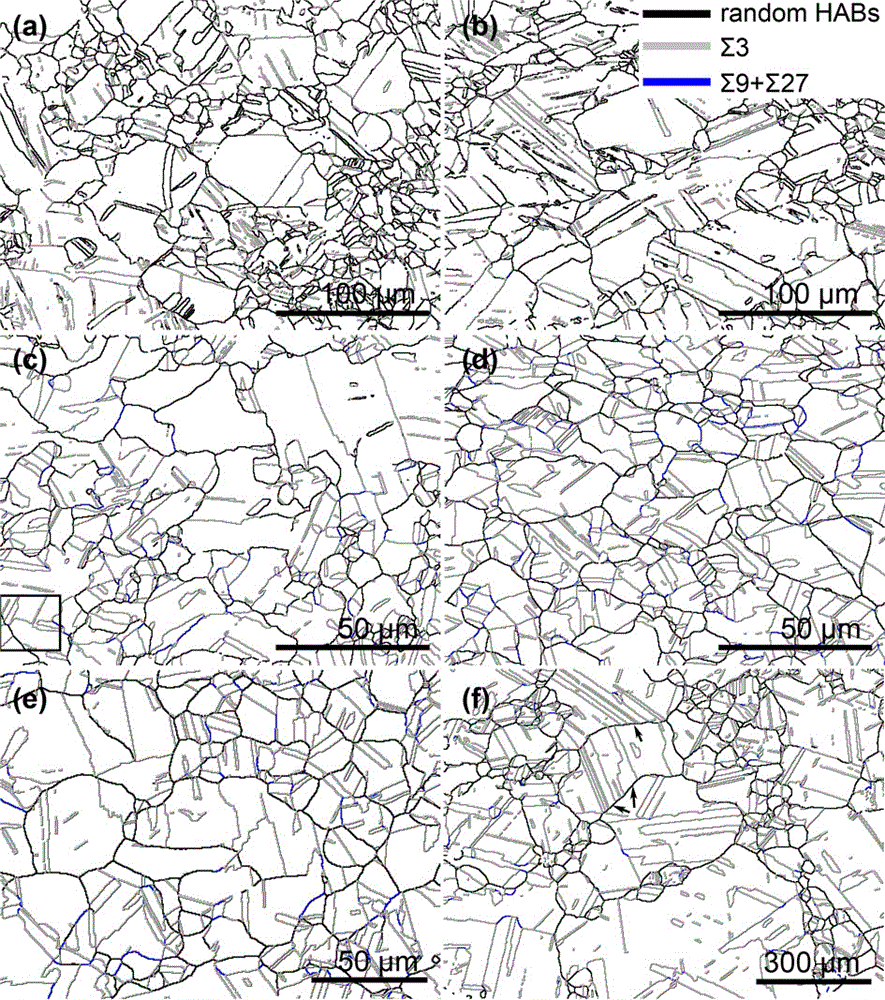

[0011] Utilize the wire cutting tool to cut the tin bronze material, the tin bronze material is specifically the tin bronze plate with a cold deformation of 5%~40%, and cut the length required by the process along the rolling direction, transverse direction and normal direction respectively to obtain a three-dimensional shape. The number of pieces, such as cutting 20, 9 and 3 millimeters respectively along the rolling direction, transverse direction and normal direction, obtains a cuboid block workpiece, and then anneals the workpiece in an environment of 400 ~ 800 ° C; the annealing process is to first place the workpiece Keep warm at 400~800℃ for 0.5~5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com