Magnetron sputtering vacuum coating equipment

A vacuum coating and magnetron sputtering technology, applied in the field of magnetron sputtering vacuum coating equipment, can solve the problems of easy interference of discharge voltage, inconvenient popularization and application, and high production cost, so as to improve film thickness uniformity and coating effect, Improve the film deposition rate and the effect of good shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

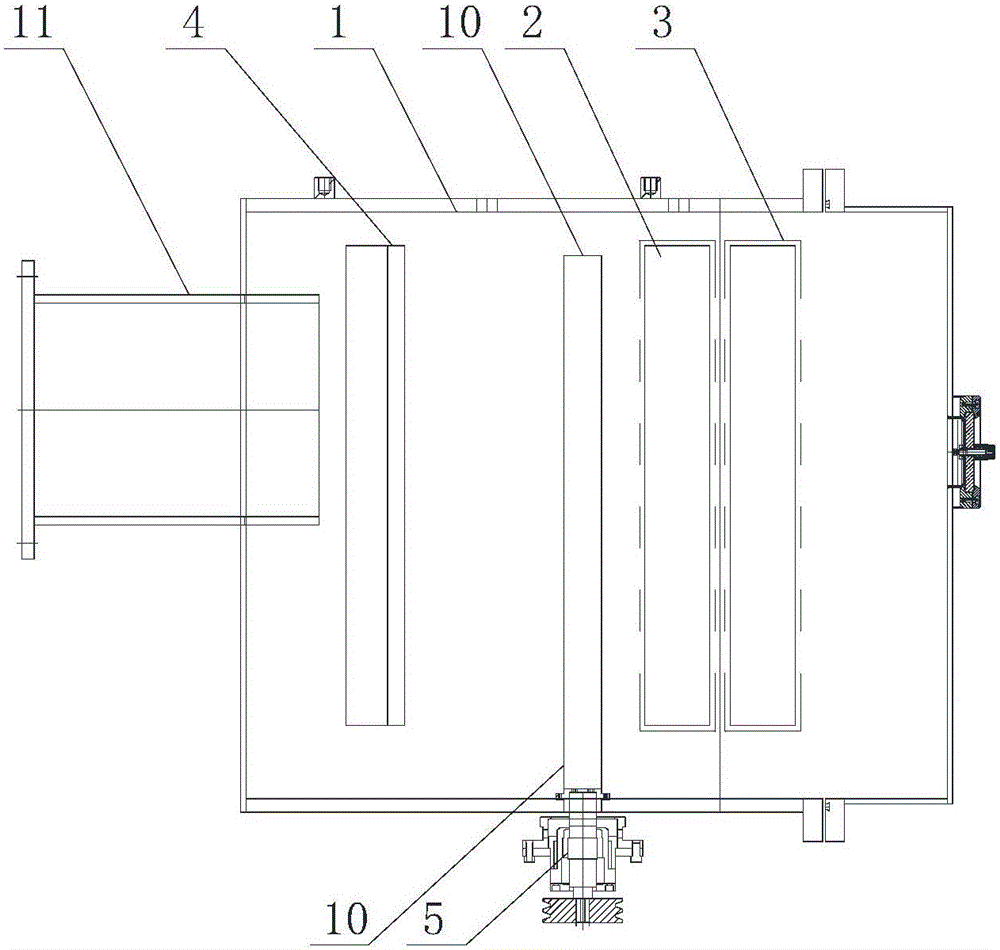

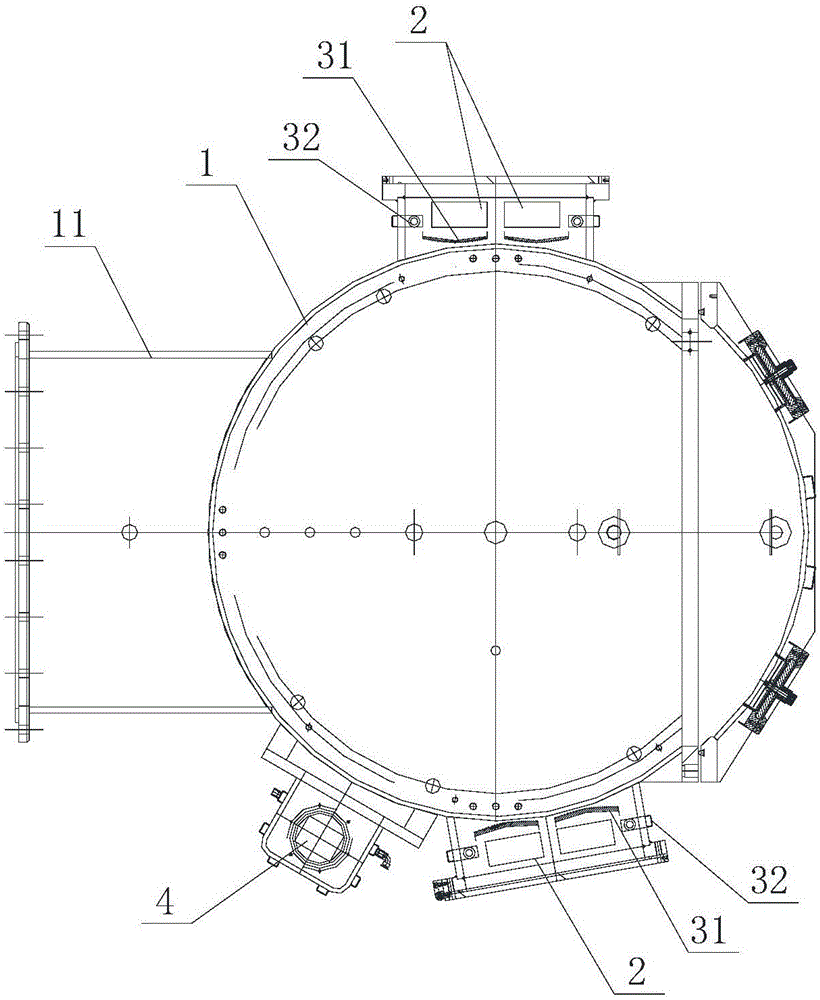

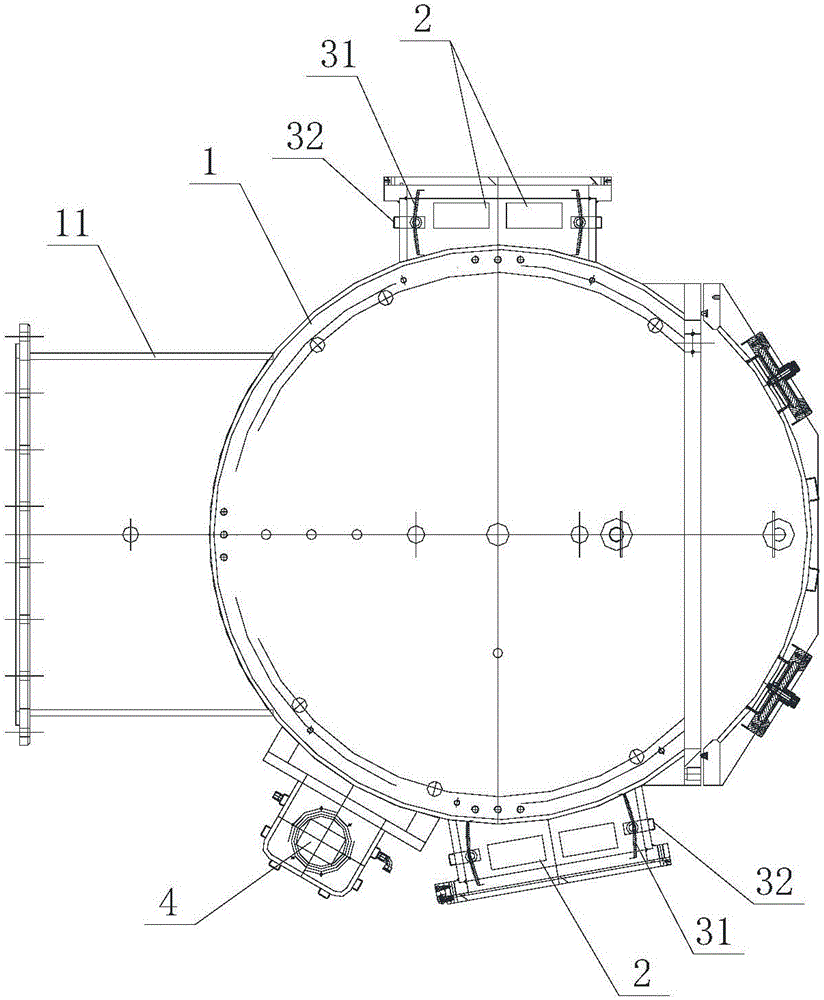

[0023] Such as Figure 1 to Figure 3 As shown, a kind of magnetron sputtering vacuum coating equipment described in the present invention includes a vacuum coating chamber 1 with a suction port 11 and a control power supply. Two groups of vertical plane twins are arranged on the side walls of the vacuum coating chamber 1. A magnetron target 2 , an open-close baffle device 3 is arranged around the planar twin magnetron target 2 , and a vertical planar ion source 4 is arranged on the side wall of the vacuum coating chamber 1 .

[0024] Such as figure 1 As shown, the planar twin magnetron target 2 includes two opposite vertical strip-shaped target heads, and the planar ion source 4 is a strip-shaped ion source standing upright on the side wall of the vacuum coating chamber 1 . The middle part in the vacuum coating chamber 1 is also provided with a rotary work platform 5 for installing the workpiece 10 to be coated and can drive the rotation of the workpiece 10 to be coated. sex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com