Seawater-electrolysis chlorine producing electrolytic bath used for resisting manganese pollution

An electrolytic cell and seawater technology, applied in the electrolytic process, electrolytic components, electrodes, etc., can solve problems such as manganese poisoning, reduced current efficiency of the electrolytic cell, and shortened anode life, so as to prolong the service life, avoid excessive falling off, and seal the effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

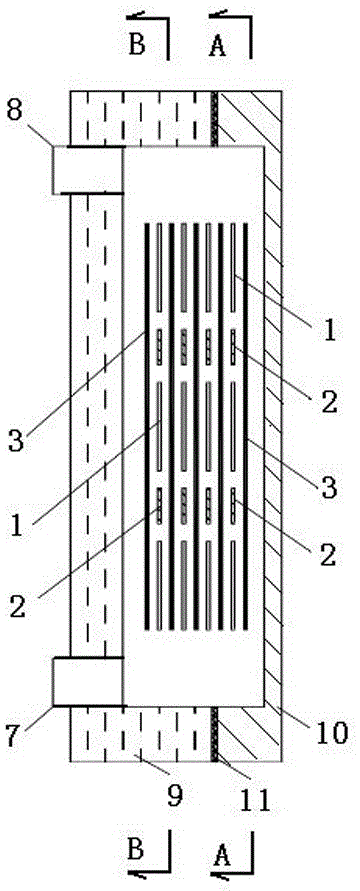

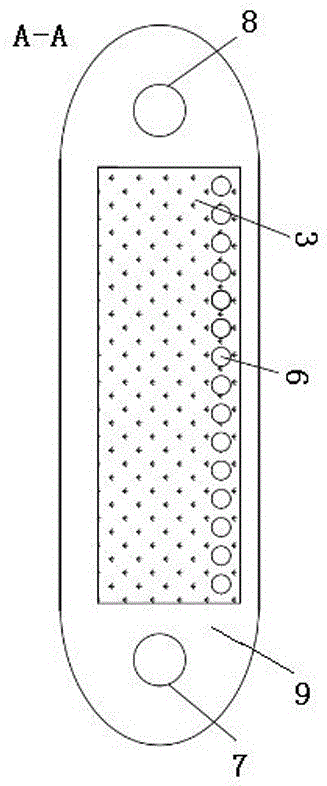

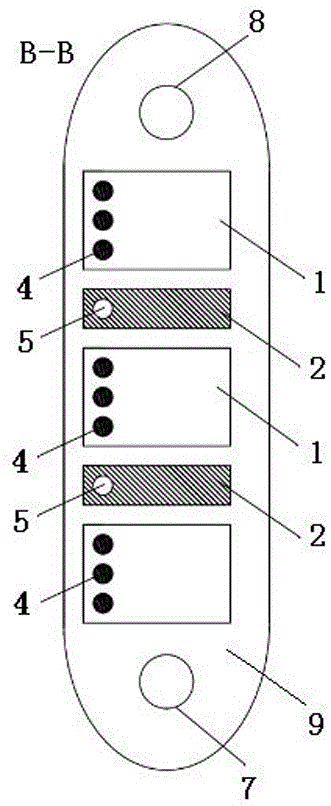

[0020] see Figure 1 ~ Figure 3 , the present invention is an electrolytic seawater chlorine production cell for anti-manganese pollution, comprising a cell body 9, a cover plate 10, a cathode 1, an anode and a conductive rod, the cell body 9 and the cover plate 10 are interlocked to form a shell, and the The cathode 1 and the anode are installed at intervals through the conductive rod in the cavity in the casing, the cathode 1 and the anode are respectively connected to the conductive rod, and one end of the conductive rod is led out of the casing to connect with the electrolysis power supply and the controller. It is characterized in that the anode includes Reverse electrolysis anodes 2 and reverse electrolysis resistant oxide anodes 3, multi-layer reverse electrolysis resistant oxide anodes 3 are arranged at equal intervals, and their plane normals are arranged horizontally; alternately in the middle of adjacent reverse electrolysis resistant oxide anodes 3 A plurality of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com