Method for preparing feed grade calcium formate

A technology of calcium formate and feed grade, which is applied in the field of preparation of feed grade calcium formate, can solve the problems of slow heating and cooling speed of the reactor, unsightly appearance of calcium formate products, long reaction time, etc., and achieve good appearance, shortened reaction time, The effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

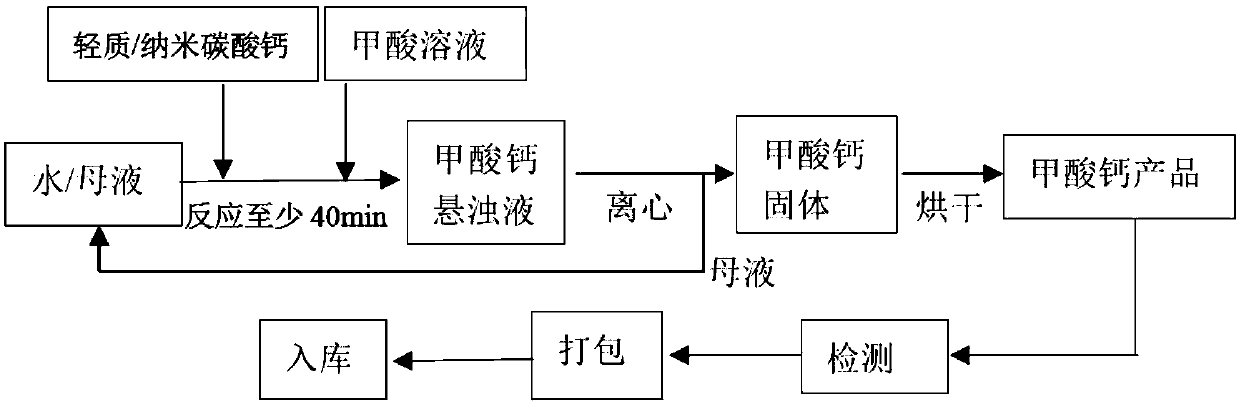

Method used

Image

Examples

Embodiment 1

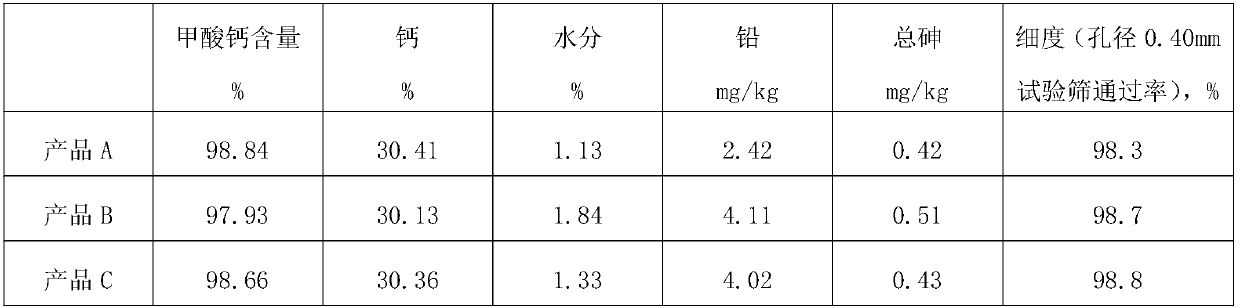

[0026] Produce feed grade calcium formate product A according to the following method:

[0027] (1) Inject 1m into the reactor 3 water, start stirring (stirring speed 80r / min).

[0028] (2) Put light calcium carbonate (CaCO3) into the reactor 3 =99.2%) 200kg, after stirring evenly, slowly adding mass concentration in the reactor is 220kg of formic acid solution of 95%; Control the addition rate of formic acid solution, the reaction temperature is maintained between 60~80 ℃.

[0029] (3) The calcium formate generated by the reaction becomes crystals and precipitates to the lower part of the reaction kettle, and continues to stir for 50 minutes, maintaining a stirring rate of 80 r / min, so that the reaction is fully carried out, and the reaction is completed to obtain a reaction product.

[0030] (4) The reaction product is sent into the centrifuge, and the centrifuge is turned on to separate the calcium formate solid and the mother liquor at a centrifugal rate of 800r / min to o...

Embodiment 2

[0034] Produce feed grade calcium formate product B according to the following method:

[0035] (1) Inject 1m into the reactor 3 The mixture of mother liquor A and water, start stirring (stirring speed 40r / min).

[0036] (2) Put light calcium carbonate (CaCO3) into the reactor 3 =98.4%) 190kg, after stirring evenly, slowly add mass concentration in reactor and be the formic acid solution 228kg of 88%; Control the addition rate of formic acid solution, the reaction temperature is maintained between 65~75 ℃.

[0037] (3) The calcium formate generated by the reaction becomes crystals and precipitates to the lower part of the reaction kettle, and continues to stir for 60 minutes, maintaining a stirring rate of 40 r / min, so that the reaction is fully carried out, and the reaction is completed to obtain a reaction product.

[0038] (4) The reaction product is sent into the centrifuge, and the centrifuge is turned on to separate the calcium formate solid and the mother liquor at a ...

Embodiment 3

[0042] Produce feed grade calcium formate product C according to the following method:

[0043] (1) Inject 1m into the reactor 3 The mixture of mother liquor B and water, start stirring (stirring speed 90r / min).

[0044] (2) Putting nano calcium carbonate (CaCO3) into the reactor 3 =98.9%) 206kg, after stirring evenly, slowly add mass concentration in reactor and be 213kg of formic acid solution of 98%; Control the addition rate of formic acid solution, the reaction temperature is maintained between 65~75 ℃.

[0045] (3) The calcium formate generated by the reaction becomes a crystal and precipitates to the lower part of the reactor, and continues to stir for 45 minutes, maintaining a stirring rate of 90 r / min, so that the reaction is fully carried out, and the reaction is completed to obtain a reaction product.

[0046] (4) The reaction product is sent into the centrifuge, and the centrifuge is turned on to separate the calcium formate solid and the mother liquor at a centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com