Silk-ramie interwoven fabric

A fabric, silk and hemp technology, applied in the field of silk and hemp interwoven fabrics, can solve problems such as strength reduction, and achieve the effects of reduced bending stiffness, high bacteriostatic rate, and improved elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

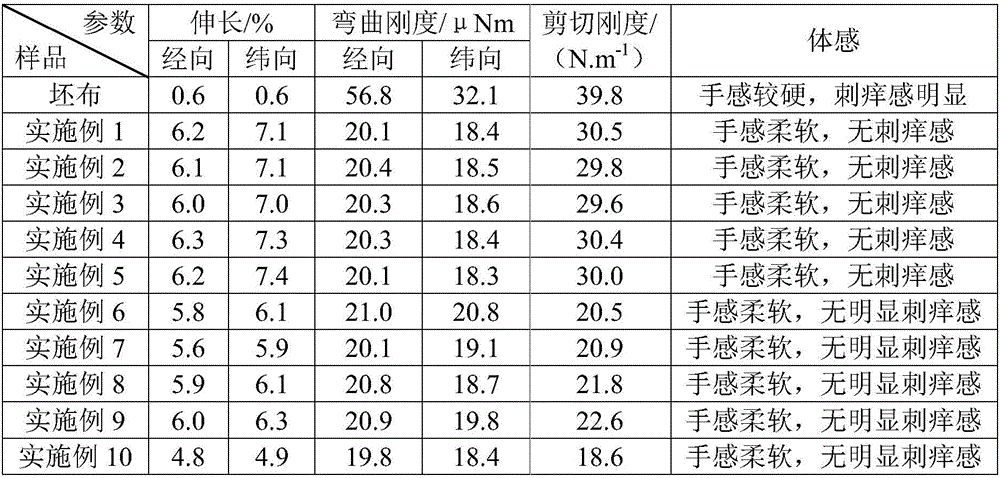

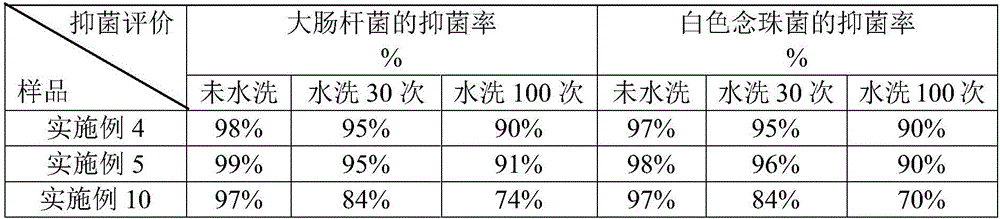

Examples

Embodiment 1-5

[0022] Embodiment 1-5: silk hemp interweaving fabric, selects for use with mulberry silk as warp yarn, ramie as weft yarn interweaving and mulberry silk denier 44dtex (40D), ramie yarn 278dtex (36N m ) interwoven fabric is gray cloth, and silk and hemp interwoven fabrics are processed sequentially as follows:

[0023] A. Singeing: Take the qualified gray cloth and perform singeing treatment at a speed of 50-55m / min;

[0024] B. Scouring: Dip the singeed gray cloth in the scouring solution at 45-50°C for two times, wash with water, dry, and the scouring time is 30-45min;

[0025] C. Finishing: Dip and roll the scoured gray cloth in softening solution at 25-30°C for 2-10 minutes;

[0026] D. Drying: Dry the finished fabric at 45-50°C until dry, then bake at 125-130°C for 1-2min;

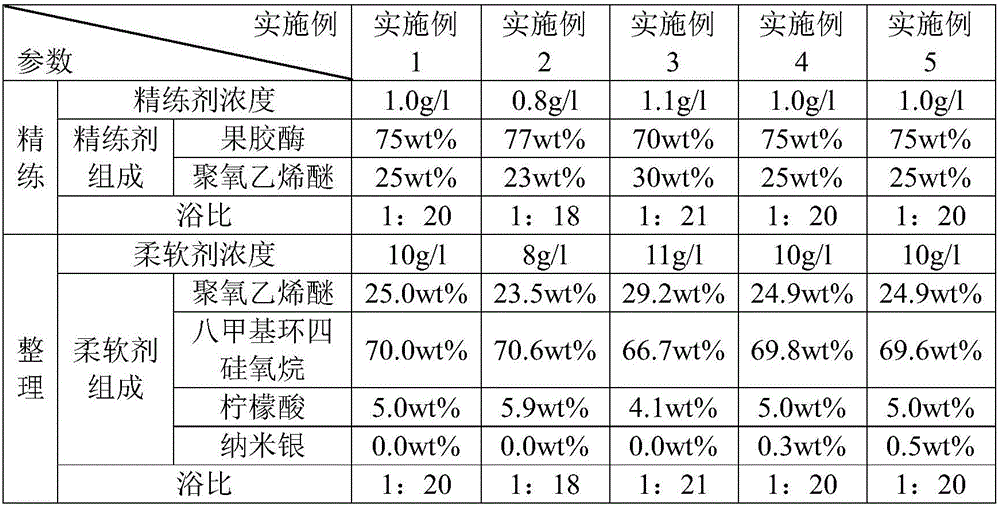

[0027] Wherein, each specific parameter among the embodiment 1-5 is as shown in table 1.

[0028] Processing parameters in table 1 embodiment 1-5

[0029]

Embodiment 6

[0030] Embodiment 6: silk and hemp interwoven fabric, the difference from embodiment 1 is that the scouring agent is changed into a mixture of 80wt% pectinase and 20wt% polyoxyethylene ether.

Embodiment 7

[0031] Embodiment 7: silk and hemp interwoven fabric, the difference from embodiment 1 is that the scouring agent is changed into a mixture of 60wt% pectinase and 40wt% polyoxyethylene ether.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com