Preparation method and material stirring device of self-adhesion type medical paper

A stirring device and self-adhesive technology, applied in the field of papermaking, can solve the problems that strength and air permeability cannot meet high requirements, and achieve the effects of improving folding endurance and strength, saving costs and avoiding losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

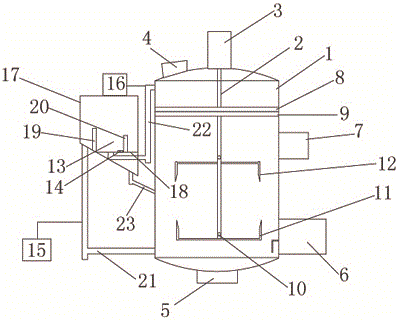

Image

Examples

Embodiment 1

[0020] Embodiment 1: A kind of preparation method of self-adhesive medical paper comprises the following steps: disintegrate into a concentration of 3% in a hydraulic disintegrator mixed with sodium bicarbonate with Yinxing and Fenya in a ratio of 1:1.5 Paper slurry, after refining the pulp, control the pulp size to 32°SR, and wet weight to 2.0g; mix the slurry evenly with the auxiliary agent gelatinized at 95°C, the auxiliary agent includes dry pulp 0.5% of the raw material and the esterified cationic modified corn starch with a minimum viscosity of 1ps.S, 6.1% of wet strength agent and 0.2% of carboxymethyl cellulose, after purifying the proportioned slurry, send it to the drying cylinder The top roll adopts fourdrinier forming drying cylinders in combination of hydraulic and air pressure for drying treatment. The pressure of the top roll of the hydraulic drying cylinder is 4Mpa, and the pressure of the top roll of the pneumatic drying cylinder is 0.4Mpa. In the middle of dry...

Embodiment 2

[0021] Embodiment 2: A kind of preparation method of medical self-adhesive type medical paper comprises the following steps: disintegrate into a concentration of 5 with Yinxing and Fenya in a hydraulic disintegrator mixed with sodium bicarbonate in a ratio of 1:0.8 % paper pulp liquid, the paper pulp liquid is subjected to pulping treatment, and the pulp size is controlled to be 33°SR, and the wet weight is 2.2g; the slurry is mixed evenly with the auxiliary agent gelatinized at 95°C, and the auxiliary agent includes absolute 0.5% of the dry slurry and the esterified cationic modified corn starch with a minimum viscosity of 1ps.S, 6.1% of wet strength agent and 0.2% of carboxymethyl cellulose, after cleaning the proportioned slurry, send it into The top roll of the drying cylinder is dried by fourdrinier forming dryers in a combination of hydraulic and air pressure. The pressure of the top roll of the hydraulic drying cylinder is 4Mpa, and the pressure of the top roll of the pn...

Embodiment 3

[0022] Embodiment 3: A kind of preparation method of self-adhesive medical paper comprises the following steps: Disintegrate into a concentration of 7% in a hydraulic disintegrator mixed with sodium bicarbonate with Yinxing and Fenya in a ratio of 1:0.43 The paper pulp liquid, the paper pulp liquid is subjected to pulping treatment, and the pulp size is controlled to be 34°SR, and the wet weight is 2.5g; the slurry is mixed evenly with the auxiliary agent gelatinized at 95°C, and the auxiliary agent includes dry 0.5% of the slurry and the esterified cationic modified corn starch with a minimum viscosity of 1ps.S, 6.1% of the wet strength agent and 0.2% of carboxymethyl cellulose, the slurry after the proportioning is purified and sent to the oven The cylinder top roll adopts fourdrinier drying cylinder drying treatment in combination of hydraulic type and pneumatic type. The hydraulic type drying cylinder top roll pressure is 4Mpa, and the pneumatic type drying cylinder top rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com