A preparation method of highly water-resistant food packaging paper and its beating and stirring device

A water-based food and stirring device technology, which is applied in pulp beating methods, textiles and papermaking, papermaking, etc., can solve the problems of softness, poor folding resistance, and low water resistance requirements, and achieve cost savings, increase strength and burst resistance Degree, the effect of avoiding loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

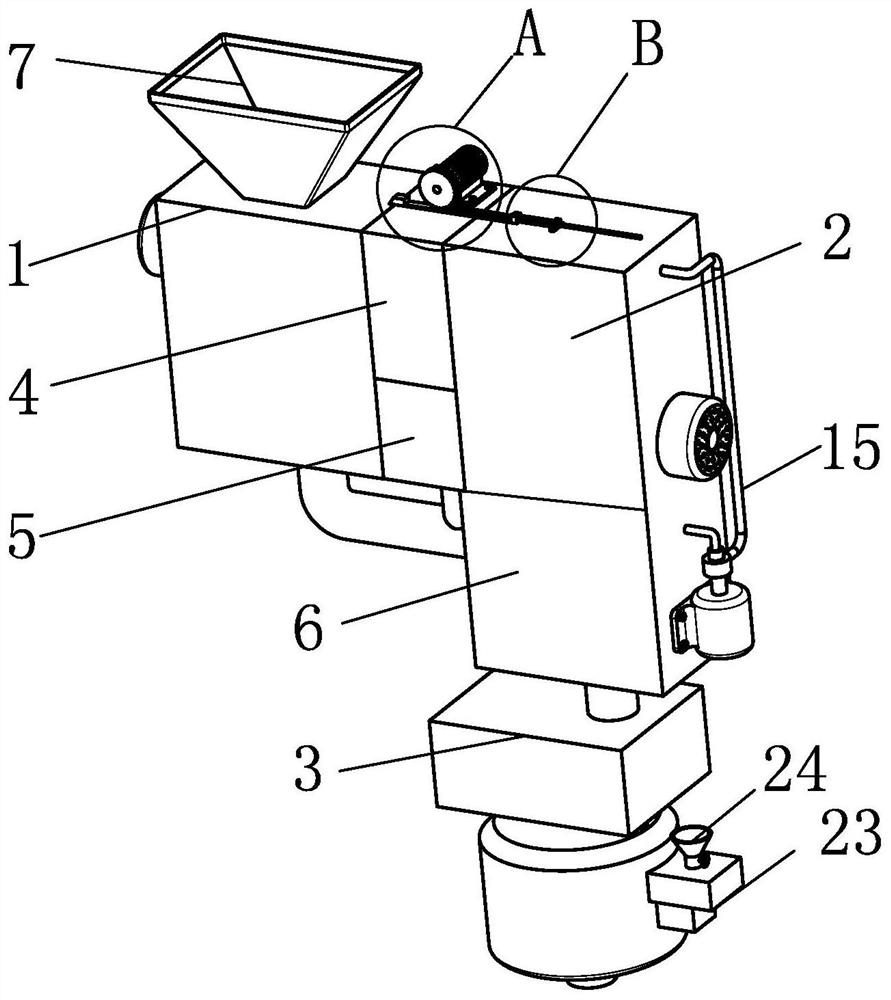

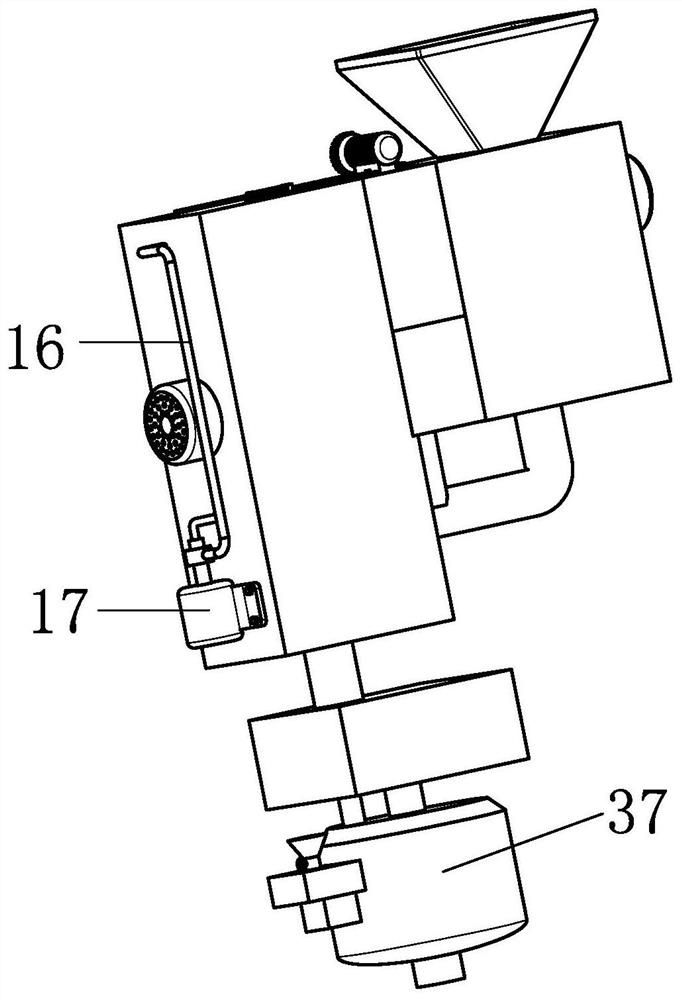

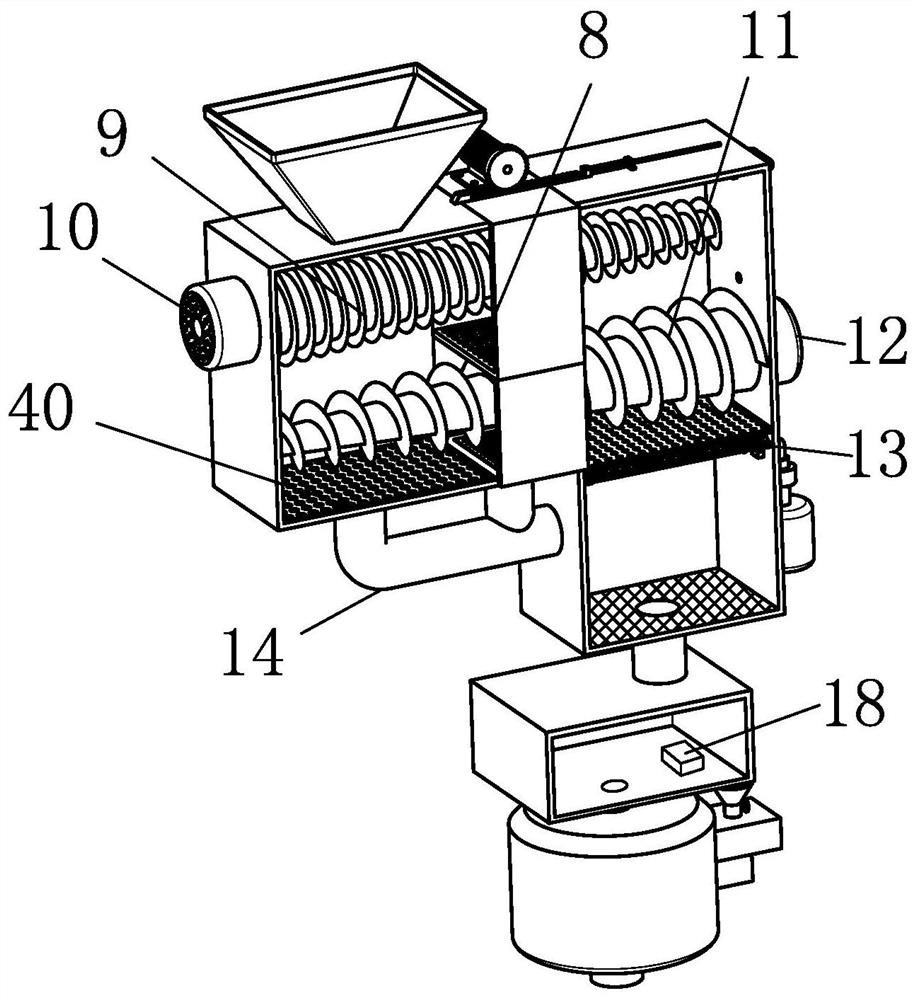

[0031]A preparation method of high water-resistance food wrapping paper, comprising the steps of: disintegrating bleached softwood pulp and hardwood pulp in a ratio of 1.5:1 into a pulp solution with a concentration of 3% in a disintegrator, passing through a beating device Processing, control the pulp degree of pulp liquid is 35 ° SR, and fiber wet weight is 3.0g, adds 0.2% food-grade wet-strength agent of absolute dry pulp total mass in the slurry after beating treatment, and the viscosity of food-grade wet-strength agent is in It is 40mpa.s at 25°C, and the pH value at 21°C is 4. Purify the proportioned slurry and dry it in multiple cylinders by fourdrinier netting. In the middle of drying, apply food-grade polyvinyl alcohol and soft The mixed solution of food grade polyvinyl alcohol, after soaking in cold water at 20°C for 1 hour, prepared to a concentration of 2%, heated to 95°C to accelerate dissolution, stirring speed 70-100r / min, stopped stirring after complete dissolut...

Embodiment 2

[0033] A preparation method of high water-resistance food wrapping paper, comprising the following steps: disintegrate bleached softwood pulp and hardwood pulp with a ratio of 2:1 in a calculator into a pulp liquid with a concentration of 5%, and pass through a beating device Processing, control the pulp degree of pulp liquid is 38 ° SR, and fiber wet weight is 3.5g, adds 1.0% food-grade wet-strength agent of absolute dry pulp total mass in the slurry after beating treatment, and the viscosity of food-grade wet-strength agent is in It is 100mpa.s at 25°C, and the PH value at 21°C is 6. Purify the proportioned slurry and dry it through fourdrinier forming in multiple cylinders. In the middle of drying, apply food-grade polyvinyl alcohol and soft The mixed solution of food grade polyvinyl alcohol, after soaking in cold water at 20°C for 1 hour, prepared to a concentration of 2%, heated to 95°C to accelerate dissolution, stirring speed 70-100r / min, stopped stirring after complete ...

Embodiment 3

[0035] A preparation method of high water-resistance food wrapping paper, comprising the following steps: disintegrate bleached softwood pulp and hardwood pulp with a ratio of 3:1 in a calculator into a pulp liquid with a concentration of 5%, and pass through a beating device Processing, control the pulp degree of pulp liquid is 40 ° SR, and fiber wet weight is 4.0g, adds 2.0% food grade wet strength agent of absolute dry pulp total mass in the slurry after beating treatment, and the viscosity of food grade wet strength agent is in It is 100mpa.s at 25°C, and the PH value at 21°C is 6. Purify the proportioned slurry and dry it through fourdrinier forming in multiple cylinders. In the middle of drying, apply food-grade polyvinyl alcohol and soft The mixed solution of food grade polyvinyl alcohol, after soaking in cold water at 20°C for 1 hour, prepared to a concentration of 2%, heated to 95°C to accelerate dissolution, stirring speed 70-100r / min, stopped stirring after complete ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com