Pipe pile with incomplete ribs

A non-integral, pipe pile technology, applied in sheet pile wall, building, foundation structure engineering, etc., can solve the problems of obvious soil squeeze effect, no obvious improvement in the physical and mechanical properties of soft soil, complicated construction plan, etc. Test the effect of sensors, accelerate the drainage and consolidation of soft soil, and improve the bearing capacity of single piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be described below in conjunction with specific embodiments.

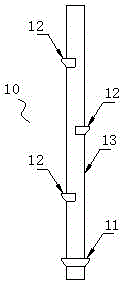

[0030] Such as Figure 1~Figure 5 As shown, the pipe pile with incomplete ribs described in the present invention includes: a hollow body 13 of the pipe pile 10, a first rib 11 is provided at the bottom of the body 13, and the first rib 11 starts from the bottom on the outside of the body 13. There are a plurality of ribs 12 distributed upward, and the ribs 12 are distributed in a staggered manner according to the outside of the main body 13 .

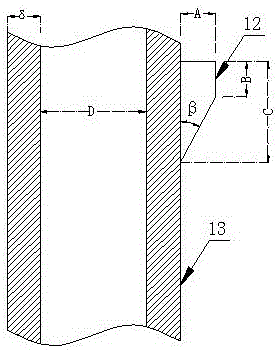

[0031] Such as image 3 As shown, a rib is composed of elements such as rib integrity, rib height C, rib thickness B, rib wall thickness A, and rib working angle β. Rib integrity refers to the ratio of the angle of a rib around the body 13 of the pipe pile to 360 degrees. The rib height C refers to the height of the rib if it is extracted separately, that is, the distance from the pinch-out point where the thickness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com