Device for sound wave transmission of while-drilling bottom pressure data and using method thereof

A pressure data and sound wave technology, applied in the field of drilling data transmission device, can solve problems such as the inability to transmit signals normally, and achieve the effect of wide application prospect, convenient use, and rapid underbalanced drilling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

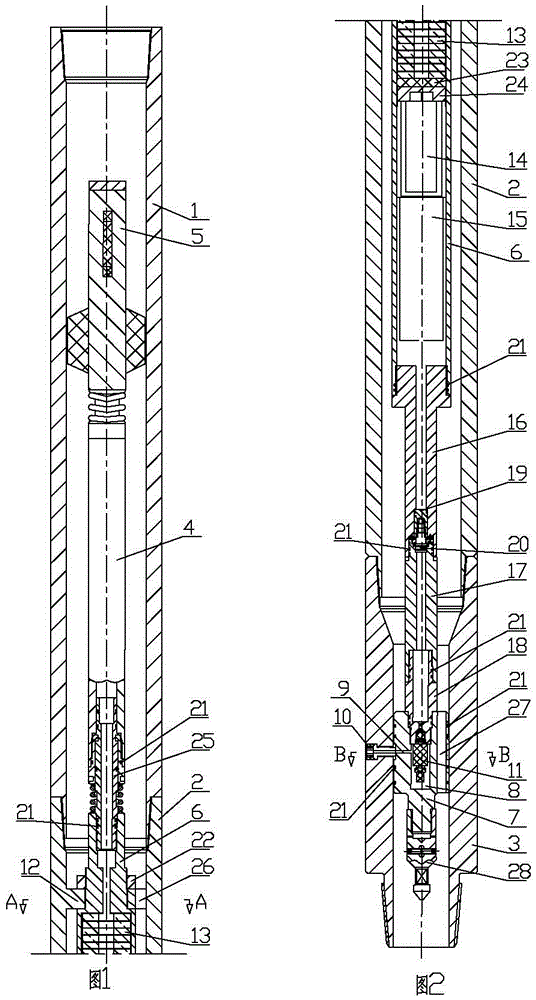

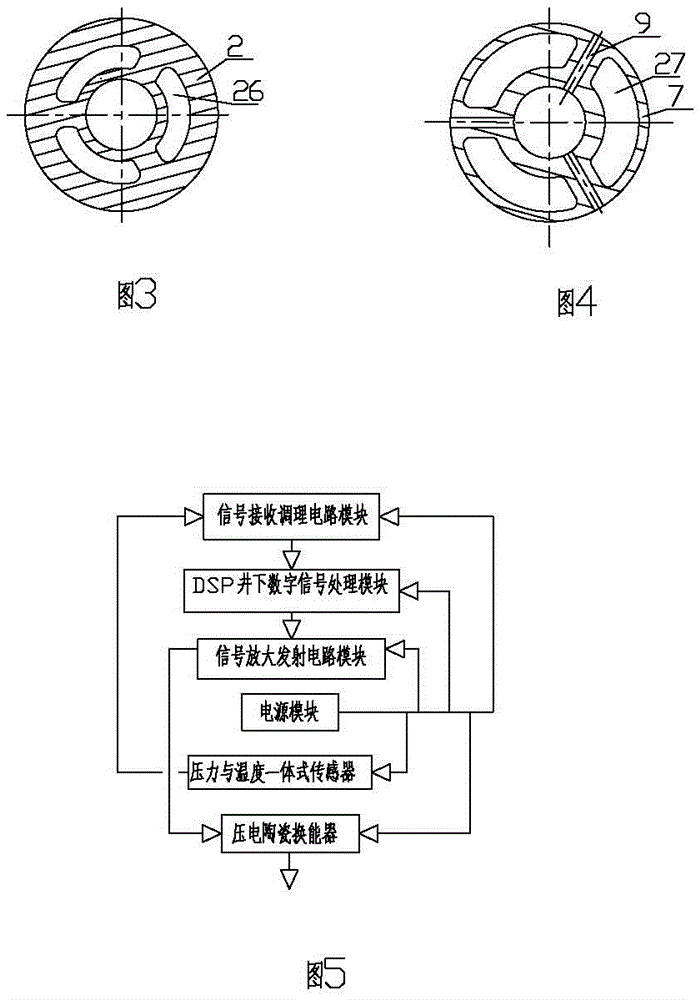

[0024] Embodiment 1: as attached Figures 1 to 5 As shown, the device for acoustic wave transmission of bottomhole pressure data while drilling includes a short drill collar 1, an outer cylinder for acoustic wave transmission 2, an outer cylinder for pressure measurement while drilling 3, a battery cylinder 4, an instrument cabin cylinder 6 and a mandrel 7, and a short drill collar 1 , the sound wave transmission outer cylinder 2 and the pressure measurement while drilling outer cylinder 3 are fixedly installed together from top to bottom in sequence, and a mandrel 7 is built in the middle of the pressure measurement while drilling outer cylinder 3, and an opening is arranged on the mandrel 7 toward The blind hole 8 on the top, at least one radial through hole 9 communicating with the blind hole 8 is distributed along the circumference in the middle of the mandrel 7, and the radial through hole 9 connected with the radial through hole 9 is distributed along the circumference in...

Embodiment 2

[0032] Embodiment 2: as attached Figure 5 As shown, the using method of the device for acoustic transmission of bottomhole pressure data while drilling is carried out as follows: the device for acoustic transmission of bottomhole pressure data while drilling described in Embodiment 1 is connected to the drill string through a short drill collar 1, and By connecting the pressure measurement while drilling outer cylinder 3 with the drill bit, the device for acoustic wave transmission of bottomhole pressure data while drilling as described in Embodiment 1 is lowered into the well, and the drilling annulus and the blind hole are connected through the radial through hole 9 and the communication hole, Make the pressure and temperature integrated sensor 11 obtain the data of annular bottomhole fluid column pressure and temperature (downhole data), and the pressure and temperature integrated sensor 11 transmit the obtained annular bottomhole fluid column pressure and temperature data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com