High-pressure silencer

A muffler and high-pressure technology, applied in muffler devices, machines/engines, sound absorption, etc., can solve the problems of human environmental hazards, inability to meet the requirements of gas noise reduction and noise reduction, and achieve good mechanical performance, high strength, and reduced mechanical effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

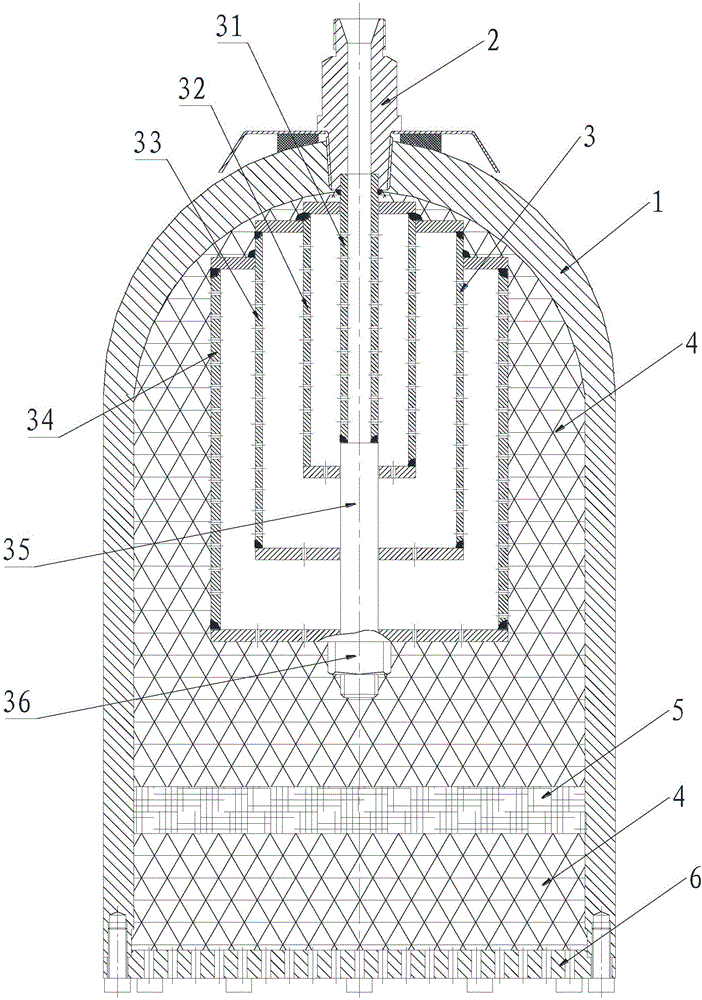

[0020] Such as figure 1 As shown, the high-pressure muffler of the present invention includes a shell 1, a muffler body 3 and a sound-absorbing material. The shell 1 is a cylinder with a spherical head at one end, and an air inlet nozzle 2 is arranged on the spherical head. The other end of the shell 1 passes through the The orifice plate 6 is closed, and an exhaust hole is arranged on the orifice plate 6 . The shell 1 is preferably made of damping alloy material. In order to avoid the influence of the weld seam on the structural strength, the shell 1 adopts a hot spinning integral molding process. In the case of complete ice blockage, it can withstand a high pressure of 35MPa and meet the ambient temperature of -40°C. ~+60°C operating requirements. The inner and outer walls of the shell 1 are sprayed with wear-resistant and anti-corrosion paint, which can adapt to workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com